solution

solution

Paper pulp is a raw material used in the manufacturing of paper and pulp-based products that play a key role in our daily life. The majority of the worlds pulp is produced by chemical pulping. As a leading global flow control solutions provider, WEIZIDOM's expertise in flow control solutions for pulp and paper ensures higher productivity, reduced downtime, and lower total cost of ownership.

For paper mills, the main media encountered in production are: pulp, steam, water, sewage and black liquor, etc. These media, in addition to the bleaching section of the pulp contains a small amount of chloride ions, washing and sieving and alkali recovery department of the black liquor containing alkali, other media less corrosive. In the entire production process of the above media in the pipeline, the pressure in the container generally does not exceed 1.6MPa. all media in the steam temperature is the highest, for 1.6MPa steam, its saturation temperature of 203 ℃.

From the above analysis of the performance of the medium can be seen, used in the production of media control valves do not have to specifically consider high temperature, high pressure, strong corrosion resistance, anti-explosion and other factors, in the selection and calculation can also be omitted such as liquid flash, blockage and high pressure difference caused by noise and other complexities.

So the main valves used in paper mills are: butterfly valves, gate valves, check valves, pressure reducing valves, traps, exhaust valves, globe valves, throttle valves, ball valves,etc.

Chemical pulping is a process by which wood or other fibrous feedstocks are processed to separate the non-cellulose components of wood, mainly lignin, from the cellulose fibers used to produce paper and other paper products. There are four chemical pulping processes used to produce paper pulp: kraft, sulfite, neutral sulfite semi-chemical (NSSC), and soda.

Strong acids and caustic alkaline bases present challenges to valves and other process equipment in Chemical pulping. Wesdom works closely with our Pulp & Paper Industry customers to deliver flow control solutions optimized for the chemical pulping process. With more than 20 years of service and a global client base, you can trust Wesdom to provide valves absolutely high-quality.

Pulp bleaching is the process by which wood pulp is whitened or brightened, without damaging the fibers. Bleaching wood pulp is accomplished by oxidizing the pulp using peroxide or chlorine which are both aggressive chemicals. Bleaching is is important for the production of not only white but also colored paper since a bleached surface is needed for dyeing.

The process also contributes to the chemical balance and removes dirt/foreign particles. Valves are essential in all stages of the pulp bleaching process including screening, cleaning, bleaching and washing/rinsing the pulp in the bleach plant and bulk bleached pulp storage. Wesdom valves are designed for exceptional performance with harsh bleaching chemicals and reliability in the pulp bleaching process.

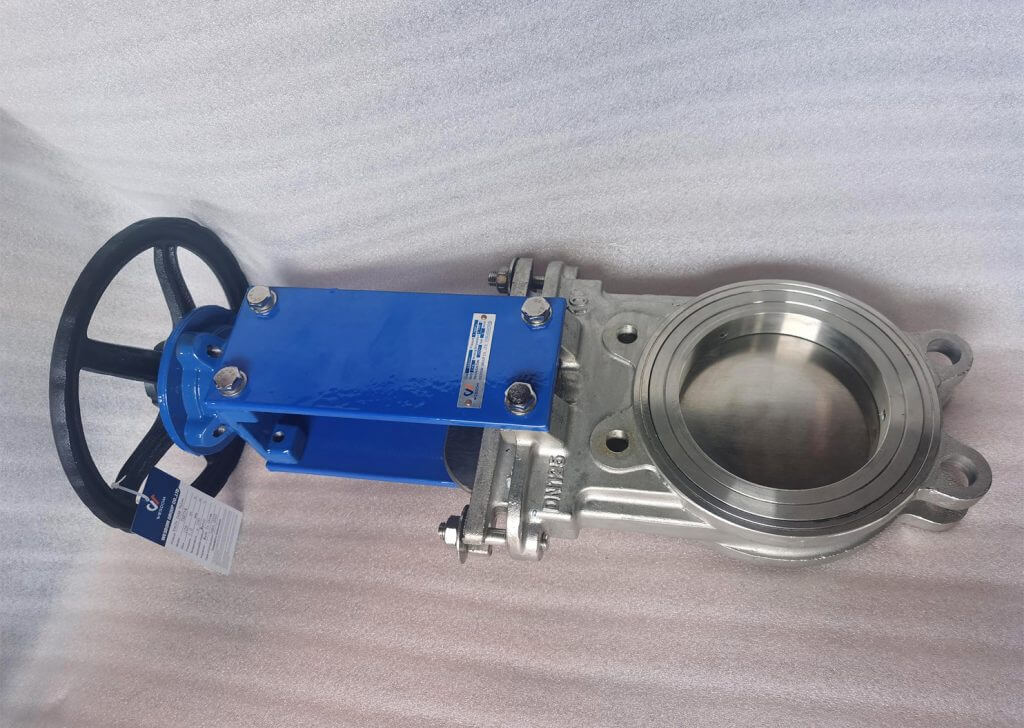

Recycling paper represents both an environmentally conscious and financially superior alternative to virgin paper pulp manufacturing. Wesdom Knife Gate Valves are engineered specifically for on/off service and isolation in pulp and paper recycle and rejects applications.

The WEIZIDOM Knife Gate Valves deliver superior performance in some of the toughest knife gate applications in the pulp and paper industry, high-cycle services that require shearing capabilities such as cyclone separators and recycle high density cleaners.

Pakistan Cardboard Factory

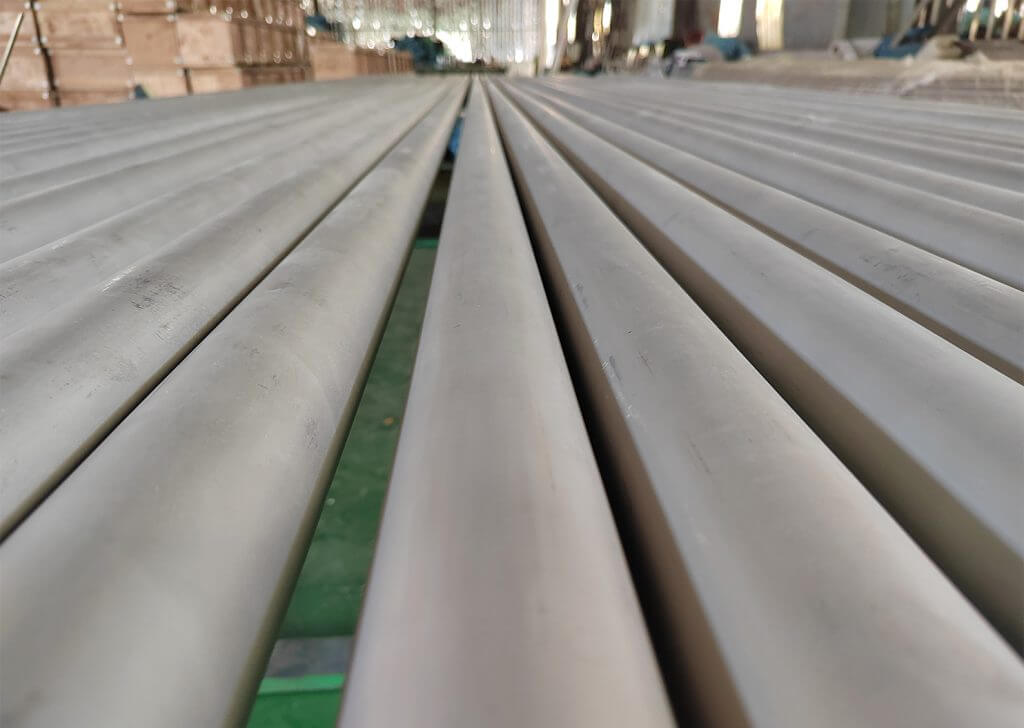

Main products: DIN SS316 seamless pipes, DIN SS316 fittings, DIN SS316 flanges, SS knife gate valves, SS316 ball valves

Although it is the first time to cooperate with each other, but the final customer also gave us a high evaluation, WEIZIDOM is very good!

Project pictures:

Email:info@wsdsolution.com

Tel:+86-17319732766