Product

Product

Cast Iron Y Type Strainer

Size: 2”~24”

Pressure Rating:PN10-40, 150LB-300LB

Material:Ductile Iron, WCB, Stainless Steel

Design Standard:EN13709,ASME B16.34

Inspection Standard:EN12266,API598

Application medium:For Water, Oil ,Gas

Application Temperature:0-200℃

Applied projects:Petroleum、Electricity、Metallurgy、Water、Sewage、Energy、Construction

The Y-type strainer is an indispensable device for the pipeline series conveying the medium. It is usually installed at the inlet end of the pressure reducing valve, pressure relief valve, fixed water level valve or other equipment to eliminate impurities in the medium to protect the valve and the normal use of the device.

Products real shot

Application

The Y-type strainer is an indispensable device for the pipeline series conveying the medium. It is usually installed at the inlet end of the pressure reducing valve, pressure relief valve, fixed water level valve or other equipment to eliminate impurities in the medium to protect the valve and the normal use of the device.

Strainer are your most economical choice for large debris removal. They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacuum conditions.

Y Strainer has the advantage of being able to be installed in either a horizontal or vertical position. However, in both cases, the screening element or “leg” must be on the “downside” of the strainer body so that entrapped solids can be properly collected and held for disposal.

Standard body materials offered are Cast Iron, Ductile Iron, Cast Steel, Stainless Steel, Chrome-Moly and Bronze. The Y-Strainer are equipped with a blow off port. A ball valve can be fitted to flush debris that is easily removable from the screen and exhaust to atmosphere or a drain system. This feature allows for easy cleaning without interrupting the process.

Cast iron strainers are designed to remove solid particles from the medium. This reduces levels of contamination and therefore maintains the quality of end product. PN40 cast iron Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Cast Iron Y strainers PN40 are very cost-effective straining solutions in many applications. Where the amount of material to be removed from the flow is relatively small, resulting in long intervals between screen cleanings, the strainer screen is manually cleaned by shutting down the line and removing the strainer cap.

For applications with heavier dirt loading, Y-Strainers can be fitted with a “blow-off” connection that permits the screen to be cleaned without removing it from the strainer body.

Cast Iron Y strainers PN40 are used in a wide variety of liquid straining applications to protect downstream process system components in many industries, including chemical processing, petroleum, power generation and marine. Water handling applications, where Y-Strainers are used to protect equipment that could be damaged or clogged by unwanted sand, gravel or other debris, are very common.

Besides steam, Cast Iron Y strainers PN40 are often used in air and natural gas applications.

Here again, high pressures are not uncommon. However, unlike steam high air pressure does not automatically mean high temperature and so, ordinary carbon steel bodies of sufficient wall thickness will generally suffice.

Construction:

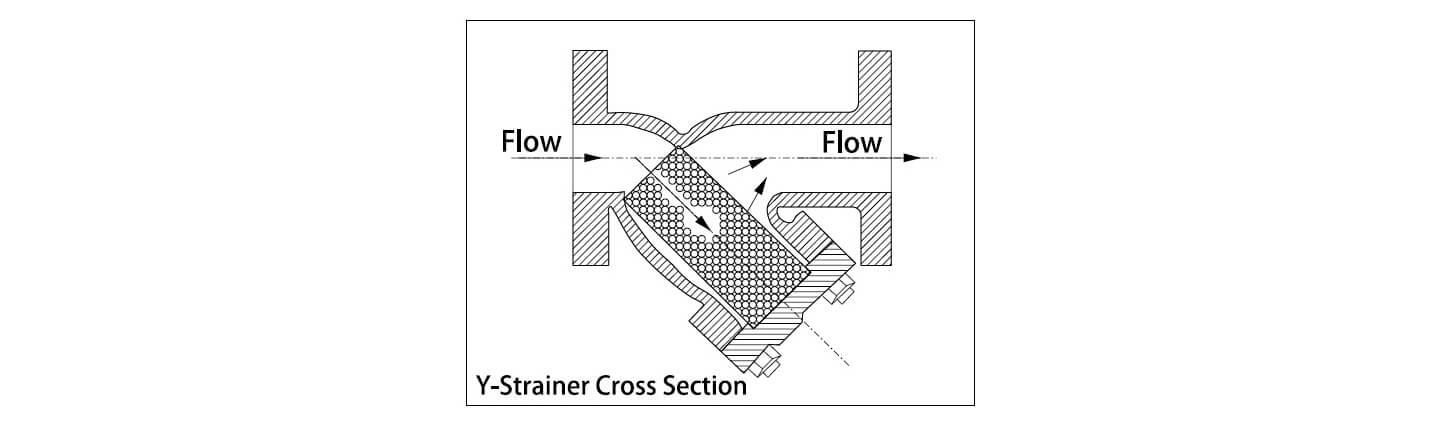

Y-Strainers are threaded or socket welded or flanged. They have a strainer basket as shown below.

Project Name: Zimbabwe LPG Project

Customer Name: A customer in Zimbabwe

Main products: API valves and fittings

Customer demand: used for oil project

project description:

WESDOM valves are applied in Zimbabwe LPG project.

The high quality products won praise from customers!

client feedback:

We received the goods in good condition. They are so nice keep it up.

Project pictures:

Products real shot

Application

Strainers are widely used in the fields of metallurgy, chemical industry, petroleum, paper making, medicine, food, mining, electric power and urban water supply.

They are used in industrial wastewater, filtration of circulating water, regeneration of emulsions, filtration of waste oil, continuous casting water systems in the metallurgical industry, blast furnace water systems, and high pressure water descaling systems for hot rolling. It is an advanced, efficient and easy to operate fully automatic filtration device.