Product

Product

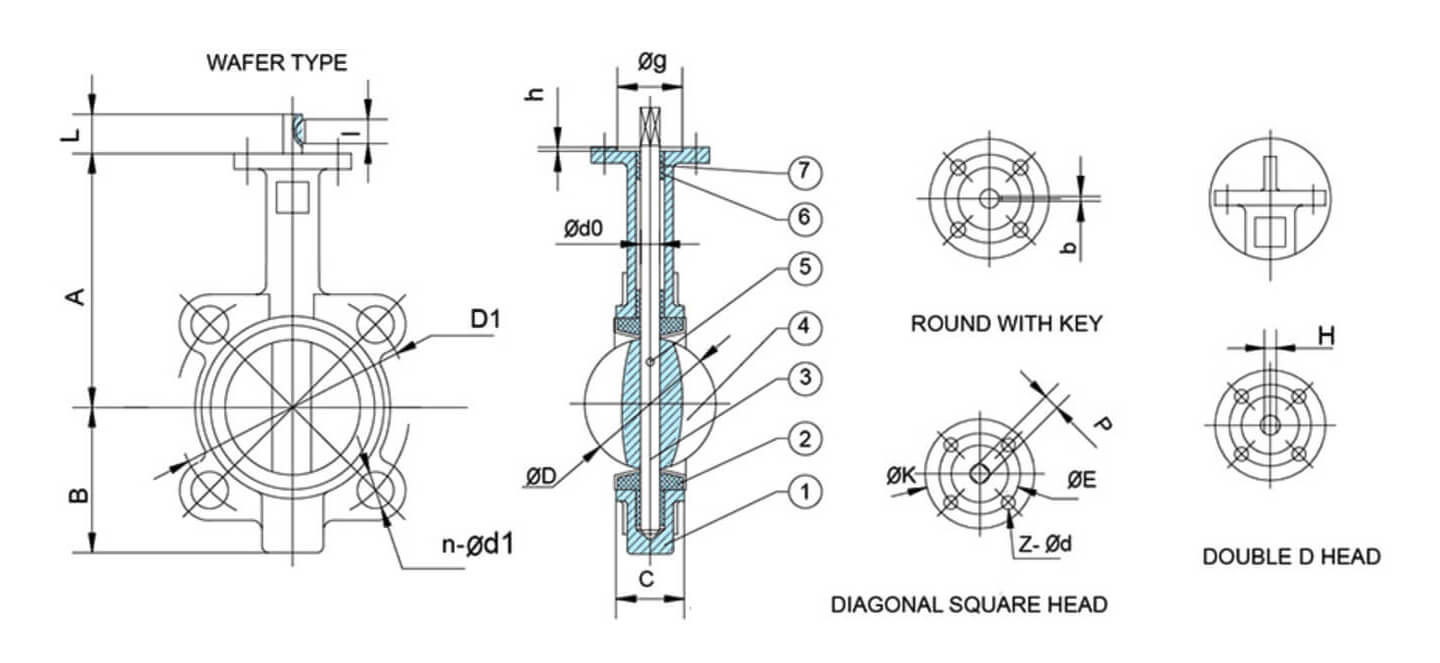

Wafer Butterfly Valve

Size:2”~32”

Pressure Rating:PN10, PN16, CL150, JIS 5K/10K

Material:Gray iron 、Ductile Iron, WCB, Stainless Steel

Design Standard: BS 5155,EN593, API 609, JIS B2064,

Inspection Standard: BS 6755, EN12266, API 598, FIS B2003-87, GB/T 13927-92,M

Application medium:water, oil, gas

Application Temperature:-10℃~150℃

Applied projects:Petroleum/Electricity/Metallurgy/Water/Sewage/Energy

Description

Wafer butterfly valve is one of the most common types of butterfly valves in the industrial pipeline, wafer butterfly valve is small structure, light weight,and only made of a few parts. Rotate only 90°can quickly open and close the valve, easy operation.

Double flange wafer butterfly valve is especially suitable for small space or short distance between pipelines, butterfly valve in the fully open position, the thickness of the valve plate is the only resistance when the medium flows through the valve body, so the pressure drop through the valve is very small, so it has a good flow control characteristics.

Commonly used butterfly valves are wafer butterfly valve and flange type butterfly valve. The wafer butterfly valve is connected between two pipe flanges with a double-headed bolt, flange butterfly valve has the flange on the ends, just need a bolt can connect the valve flange and the pipe flange together.

Features

1.wafer butterfly valve can be configured with pneumatic, electric, hydraulic, manual devices according to customer’s requirement to meet the needs of remote control and program control ;

2.Compared to gate valve, butterfly valve is small size, occupy small space ;

3.The butterfly valve has two seal types: resilient seal and metal seal. resilient seal butterfly valve, seal ring can be inlaid on the valve body or attached to the butterfly plate around, resilient seal butterfly valve has good seal performance;

4.The clever wedge design makes the valve have the automatic sealing function of the closer and tighter, and the sealing surface has the compensatory function, which can ultilize zero leakage;

5.The lining can replaced withgood anti-corrosion materials, which can adapt to corrosive, strong acid medium ;

Material:

| Body | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Disc | Ductile Iron, Carbon Steel, Stainless Steel |

| Stem | Stainless Steel |

| Seat | EPDM, NBR, PTFE, VITON, HYPALON |

| O ring | EPDM, NBR |

Parameters:

| SIZE | A | B | C | L | DIN PN 10 | DIN PN 16 | ANSI 150LB | JIS 10K | ISO5211 | Top Flange | B1XB1 | nb | |||||||

| DN | NPS | øK | N-ød | øK | N-ød | øK | N-ød | øK | N-ød | øD | øD1 | N-øG | |||||||

| 40 | 1.5″ | 67 | 141 | 32 | 33 | 110 | 4-ø18 | 110 | 4-ø18 | 98.5 | 4-ø16 | 105 | 4-ø19 | 65 | 50 | 4-ø8 | F05 | 9X9 | |

| 50 | 2″ | 67 | 141 | 32 | 43 | 125 | 4-ø18 | 125 | 4-ø18 | 120.6 | 4-ø19 | 120 | 4-ø19 | 65 | 50 | 4-ø8 | F05 | 9X9 | |

| 65 | 2½” | 75 | 151 | 32 | 46 | 145 | 4-ø18 | 145 | 4-ø18 | 139.7 | 4-ø19 | 140 | 4-ø19 | 65 | 50 | 4-ø8 | F05 | 9X9 | |

| 80 | 3″ | 95 | 160 | 32 | 46 | 160 | 8-ø18 | 160 | 8-ø18 | 152.4 | 4-ø19 | 150 | 8-ø19 | 65 | 50 | 4-ø8 | F05 | 9X9 | |

| 100 | 4″ | 111 | 180 | 32 | 52 | 180 | 8-ø18 | 180 | 8-ø18 | 190.5 | 8-ø19 | 175 | 8-ø19 | 90 | 70 | 4-ø10 | F07 | 11X11 | |

| 125 | 5″ | 129 | 193 | 32 | 56 | 210 | 8-ø18 | 210 | 8-ø18 | 215.9 | 8-ø22.4 | 210 | 8-ø23 | 90 | 70 | 4-ø10 | F07 | 14X14 | |

| 150 | 6″ | 142 | 207 | 32 | 56 | 240 | 8-ø22 | 240 | 8-ø22 | 241.3 | 8-ø22.4 | 240 | 8-ø23 | 90 | 70 | 4-ø10 | F07 | 14X14 | |

| 200 | 8″ | 170 | 240 | 45 | 60 | 295 | 8-ø22 | 295 | 12-ø22 | 298.4 | 8-ø22.4 | 290 | 12-ø23 | 125 | 102 | 4-ø12 | F10 | 17X17 | |

| 250 | 10″ | 206 | 270 | 45 | 68 | 350 | 12-ø22 | 355 | 12-ø22 | 361.9 | 12-ø25.4 | 355 | 12-ø25 | 125 | 102 | 4-ø12 | F10 | 22X22 | |

| 300 | 12″ | 238 | 316 | 45 | 78 | 400 | 12-ø22 | 410 | 12-ø26 | 431.8 | 12-ø25.4 | 400 | 16-ø25 | 125 | 102 | 4-ø12 | F10 | 22X22 | |

| 350 | 14″ | 267 | 368 | 45 | 78 | 460 | 16-ø22 | 470 | 16-ø26 | 476.2 | 12-ø28.4 | 445 | 16-ø25 | 125 | 102 | 4-ø12 | F10 | 22X22 | |

| 400 | 16″ | 298 | 400 | 51 | 86 | 515 | 12-ø26 | 525 | 16-ø30 | 539.7 | 16-ø28.4 | 510 | 16-ø27 | 175 | 140 | 4-ø18 | F14 | 1–10 | |

| 450 | 18″ | 318 | 422 | 51 | 105 | 565 | 20-ø26 | 585 | 20-ø30 | 577.8 | 16-ø31.8 | 565 | 20-ø27 | 175 | 140 | 4-ø18 | F14 | 1–10 | |

| 500 | 20″ | 349 | 479 | 57 | 130 | 620 | 20-ø26 | 650 | 20-ø33 | 635 | 20-ø31.8 | 620 | 20-ø27 | 175 | 140 | 4-ø18 | F14 | 1–12 | |

| 600 | 24″ | 410 | 562 | 70 | 152 | 725 | 20-ø30 | 770 | 20-ø36 | 749.3 | 20-ø35.1 | 730 | 24-ø33 | 210 | 165 | 4-ø22 | F16 | 1–16 | |

Project location: Tanzania

Application industry: Water Project

Main products: Gate Valves, wafer Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

We have three branch companies all over the world, Tanzania branch company is the one. Before receiving the order, we did many works to the customer, we visit customer’s factory, learn the project field situation and measure the data on the site, so we gave the proper solution and quotation to our customer, which is highly recognized by the customer and customer decided to cooperate with WESDOM. after valves and fittings arrive to the site, we also arranged engineer to guide for installation.

Application