Product

Product

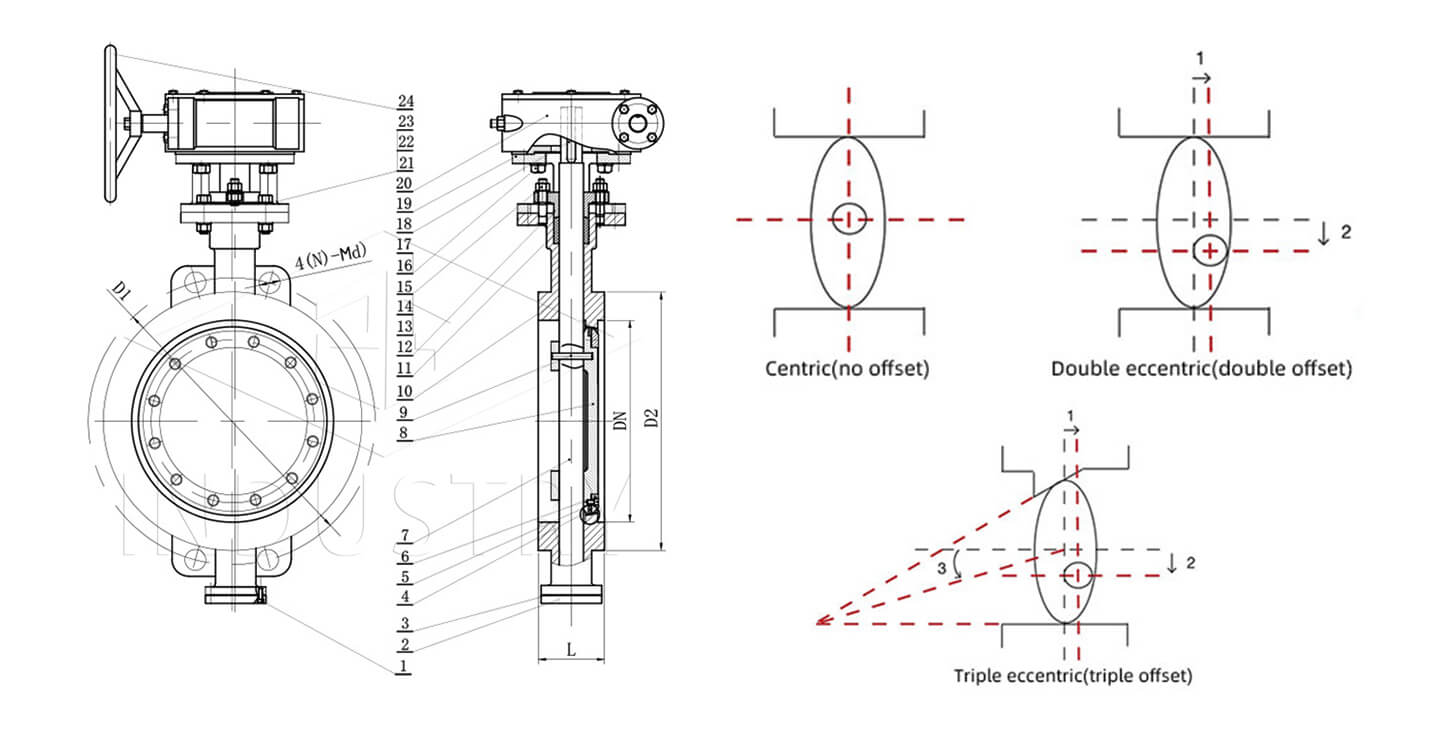

Three eccentric metal seals wafer butterfly valve

Size:2~48"(DN50~DN1200)

Pressure Rating:PN10,PNPN16-PN40,150LB-300LB,5K-16K

Material:WCB,Stainless Steel,Cr -Mo steel,Allay steel

Design Standard: BS 5155,API609,JIS B2064

Inspection Standard: EN12266, API 598, GB/T 13927-92

Application medium:Water, Sewage, Gas

Application Temperature:-29-300℃

Applied projects:Petroleum/Electricity/Metallurgy/Water/Sewage/Energy/Construction

The range of WESDOM valves can be used for overground installation, in valve chambers and buried systems. It includes a full range of operating accessories and actuators.

WESDOM valves are installed all over the Asia,Africa continent, the Middle East and throughout Europe. They have justifiably acquired a faultless reputation for their durability, reliability and quality worldwide.

The valve stem axis deviates from the center of the disc and the center of the body at the same time, and the rotation axis of the valve seat has a certain angle with the axis of the valve body passage, which is called a triple eccentric butterfly valve.

The biggest feature of the triple eccentric butterfly valve is that the sealing structure is fundamentally changed. It is no longer a position seal, but a torsion seal, that is, it does not rely on the elastic deformation of the valve seat, but completely relies on the contact surface pressure of the valve seat to achieve the sealing effect. Therefore, the problem of zero leakage of the metal valve seat is solved in one fell swoop, and because the contact surface pressure is proportional to the medium pressure, the high pressure and high temperature resistance can also be solved easily.

The range of WESDOM valves can be used for overground installation, in valve chambers and buried systems. It includes a full range of operating accessories and actuators.

WESDOM valves are installed all over the Asia,Africa continent, the Middle East and throughout Europe. They have justifiably acquired a faultless reputation for their durability, reliability and quality worldwide.

Features:

1.The triple eccentric butterfly valve integrates adjustment and cut-off, with strong controllability.

The triple eccentric butterfly valve produced by wesdom valve is designed with double safety structure to prevent the deformation of the butterfly plate, the misalignment of the valve stem, and the biting of the sealing surface caused by the influence of fluid pressure and temperature. The wesdom valve is equipped with two independent thrust rings on the lower side of the butterfly plate, so as to ensure the normal operation of the triple eccentric butterfly valve under any working conditions;

2.No dead zone design, small opening torque.

The shape of the valve plate of the triple eccentric butterfly valve is an elliptical cone, and its surface is welded with hard alloy, which has excellent wear resistance. The floating U-shaped stainless steel seat has the function of automatically adjusting the center. When the valve is opened, the elliptical cone sealing surface valve plate first detaches from the U-shaped elastic valve seat, and then rotates.

The seat applies pressure to deform the valve seat until the valve seat closely matches the oval conical sealing surface of the valve plate. The butterfly plate does not scratch the valve seat when the valve is opened and closed, and the torque of the valve stem is directly transmitted to the sealing surface through the butterfly plate, and the opening torque is small, thereby eliminating the common jumping phenomenon when opening the valve.

3.Zero leakage, high temperature and high pressure resistance.

The biggest feature of triple eccentricity is that it fundamentally changes the sealing structure. It is no longer a positional seal, but a torsion seal, that is, it does not rely on the elastic deformation of the valve seat, but completely relies on the contact surface pressure of the valve seat to achieve the sealing effect.

This kind of sealing structure enables the triple eccentric butterfly valve to achieve hard sealing VI level, achieving true zero leakage. At the same time, due to the selection of the metal valve seat and the structural characteristics of the face seal, the problem of high temperature and high pressure resistance is also solved.

Standard:

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Special Test: On request, any other test can be carried out according to special instruction by client.

| DN | L | H | D373H/Y | D673H | 0.6MPA | 1.0MPA | ||||||

| H1 | A1 | B1 | H2 | A2 | B2 | D1 | Z-d | D1 | Z-d | |||

| 50 | 43 | 112 | 350 | 180 | 200 | 625 | 245 | 72 | 110 | 4–14 | 125 | 4–18 |

| 65 | 46 | 115 | 370 | 180 | 200 | 625 | 245 | 72 | 130 | 4–14 | 145 | 4–18 |

| 80 | 49 | 120 | 380 | 180 | 200 | 645 | 245 | 72 | 150 | 4–18 | 160 | 8–18 |

| 100 | 56 | 138 | 420 | 180 | 200 | 645 | 355 | 92 | 170 | 4–18 | 180 | 8–18 |

| 125 | 64 | 164 | 460 | 180 | 200 | 715 | 355 | 92 | 200 | 8–18 | 210 | 8–18 |

| 150 | 70 | 175 | 555 | 270 | 280 | 800 | 250 | 92 | 225 | 8–18 | 240 | 8–22 |

| 200 | 74 | 208 | 605 | 270 | 280 | 850 | 250 | 170 | 280 | 8–18 | 295 | 8–22 |

| 250 | 76 | 243 | 680 | 380 | 280 | 925 | 450 | 170 | 335 | 12–18 | 350 | 12–22 |

| 300 | 83 | 283 | 800 | 380 | 420 | 1035 | 450 | 200 | 395 | 12–22 | 400 | 12–22 |

| 350 | 92 | 310 | 835 | 380 | 420 | 1070 | 450 | 220 | 445 | 12–22 | 560 | 16–22 |

Famous Textile Factory Project in Pakistan

Main products:

Flow meters and SS valves

Project description:

This is a relatively special case. Because the customer know less about valves, but the demand is very large. So WESDOM assigns a professional team (salesmen and engineers from the International Trade Department) to conduct on-site inspections and give customer some Pertinent suggestions, and this customer are very shocked and moved by our service, and have established a long-term cooperative relationship with us without hesitation;

Client feedback:

The customer said: “Thank you very much for the on-the-spot inspection and very professional guidance of the WESDOM team.” He was really shocked by the warm and considerate service and professional technical guidance of WESDOM. WESDOM is trustworthy!

Project pictures:

Application

The triple eccentric butterfly valve is widely used in metallurgy, electric power, petrochemical, water supply and drainage, and municipal construction and other industrial pipelines with a medium temperature of 425 ℃ or less to adjust the flow rate and load and cut off the fluid.

The maximum pressure rating of the triple eccentric butterfly valve produced by wesdom Valve can reach 2500 pounds, and the standard diameter can reach 120 inches.

The connection mode of the triple eccentric butterfly valve: the clamp, the lug, the flange, the ring connection, the butt welding, the jacket, etc. can be selected, and various structural lengths and standards can be corresponded.

The triple eccentric butterfly valve has a large choice of materials, high and low temperature, and various acids, alkalis and other corrosive media.

Which is widely used in medium temperature under 425°c of metallurgical, power, petrochmical, and municipal construction, drainage and industrial pipe, for regulating traffice and truncated fluid to use.