Product

Product

Stainless Steel Wafer Butterfly Valve

Size:2”~40”

Pressure Rating:PN10, PN16, CL150, JIS 5K/10K

Material:SS304, SS316

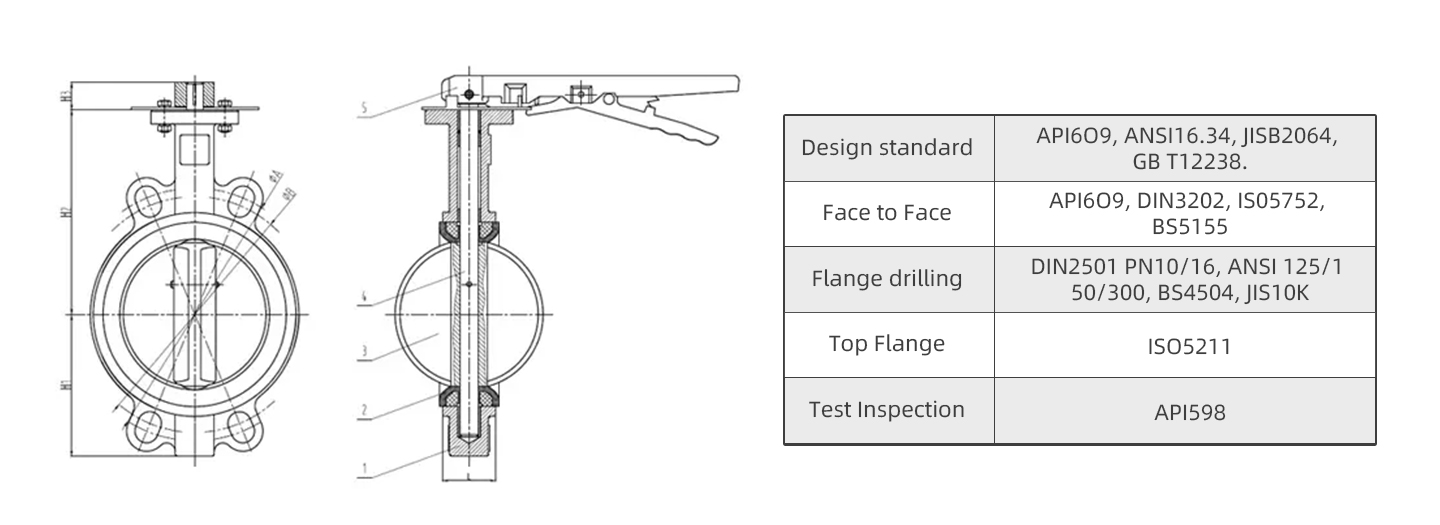

Design Standard: EN 593, MSS SP67, API 609, BS5155

Inspection Standard: API 598, ISO 5208, EN 12266

Application medium:water, oil and gas

Application Temperature:-10 °C to 150°C

Applied projects:Petroleum/Electricity/Metallurgy/Water/Sewage/Energy/Construction

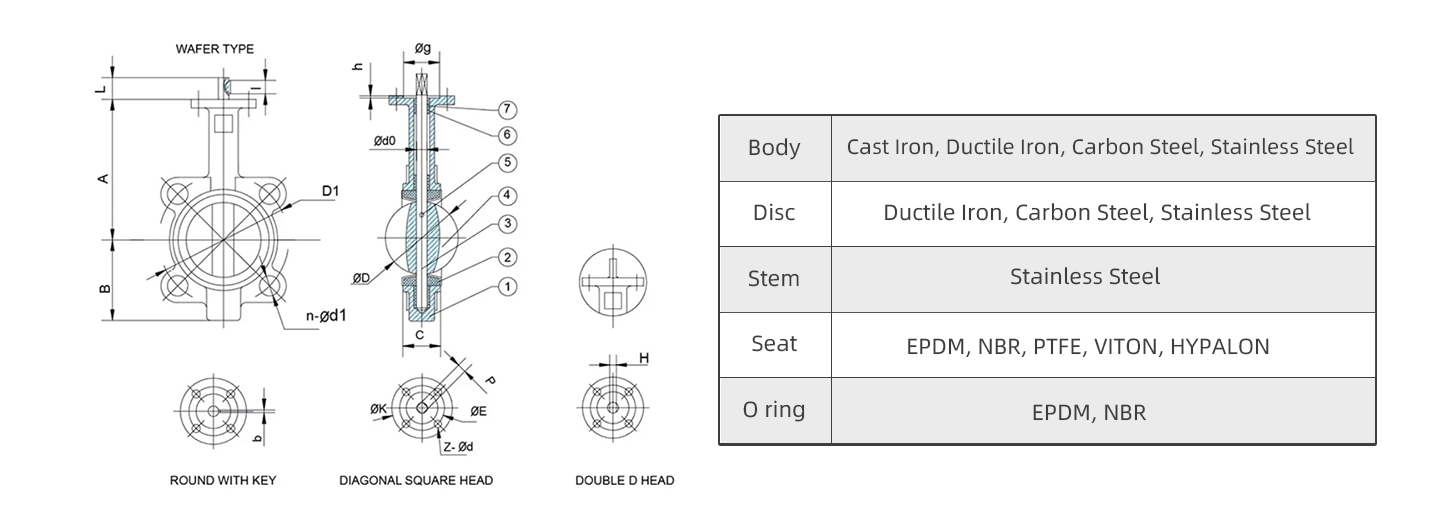

| SIZE | A | B | C | L | ANSI 150B | DIN PN 10 | DIN PN 16 | JIS 10K | ISO 5211 | Top Flange | |||||||

| mm | in | øK | N-ød | øK | N-ød | øK | N-ød | øK | N-ød | øD | øD1 | N-øG | |||||

| 40 | 1.5″ | 67 | 141 | 32 | 33 | 98.5 | 4-ø16 | 110 | 4-ø18 | 110 | 4-ø18 | 105 | 4-ø19 | 65 | 50 | 4-ø8 | F05 |

| 50 | 2″ | 67 | 141 | 32 | 43 | 120.6 | 4-ø19 | 125 | 4-ø18 | 125 | 4-ø18 | 120 | 4-ø19 | 65 | 50 | 4-ø8 | F05 |

| 65 | 2½” | 75 | 151 | 32 | 46 | 139.7 | 4-ø19 | 145 | 4-ø18 | 145 | 4-ø18 | 140 | 4-ø19 | 65 | 50 | 4-ø8 | F05 |

| 80 | 3″ | 95 | 160 | 32 | 46 | 152.4 | 4-ø19 | 160 | 8-ø18 | 160 | 8-ø18 | 150 | 8-ø19 | 65 | 50 | 4-ø8 | F05 |

| 100 | 4″ | 111 | 180 | 32 | 52 | 190.5 | 8-ø19 | 180 | 8-ø18 | 180 | 8-ø18 | 175 | 8-ø19 | 90 | 70 | 4-ø10 | F07 |

| 125 | 5″ | 129 | 193 | 32 | 56 | 215.9 | 8-ø22.4 | 210 | 8-ø18 | 210 | 8-ø18 | 210 | 8-ø23 | 90 | 70 | 4-ø10 | F07 |

| 150 | 6″ | 142 | 207 | 32 | 56 | 241.3 | 8-ø22.4 | 240 | 8-ø22 | 240 | 8-ø22 | 240 | 8-ø23 | 90 | 70 | 4-ø10 | F07 |

| 200 | 8″ | 170 | 240 | 45 | 60 | 298.4 | 8-ø22.4 | 295 | 8-ø22 | 295 | 12-ø22 | 290 | 12-ø23 | 125 | 102 | 4-ø12 | F10 |

| 250 | 10″ | 206 | 270 | 45 | 68 | 361.9 | 12-ø25.4 | 350 | 12-ø22 | 355 | 12-ø26 | 355 | 12-ø25 | 125 | 102 | 4-ø12 | F10 |

| 300 | 12″ | 238 | 316 | 45 | 78 | 431.8 | 12-ø25.4 | 400 | 12-ø22 | 410 | 12-ø26 | 400 | 16-ø25 | 125 | 102 | 4-ø12 | F10 |

| 350 | 14″ | 267 | 368 | 45 | 78 | 476.2 | 12-ø28.4 | 460 | 16-ø22 | 470 | 16-ø26 | 445 | 16-ø25 | 125 | 102 | 4-ø12 | F10 |

| 400 | 16″ | 298 | 400 | 51 | 86 | 539.7 | 16-ø28.4 | 515 | 12-ø26 | 525 | 16-ø30 | 510 | 16-ø27 | 175 | 140 | 4-ø18 | F14 |

| 450 | 18″ | 318 | 422 | 51 | 105 | 577.8 | 16-ø31.8 | 565 | 20-ø26 | 585 | 20-ø30 | 565 | 20-ø27 | 175 | 140 | 4-ø18 | F14 |

| 500 | 20″ | 349 | 479 | 57 | 130 | 635 | 20-ø31.8 | 620 | 20-ø26 | 650 | 20-ø33 | 620 | 20-ø27 | 175 | 140 | 4-ø18 | F14 |

| 600 | 24″ | 410 | 562 | 70 | 152 | 749.3 | 20-ø35.1 | 725 | 20-ø30 | 770 | 20-ø36 | 730 | 24-ø33 | 210 | 165 | 4-ø22 | F16 |

Material:

Features:

1、The length of the short structure can save raw materials and installation space, and also effectively support the strength of the pipeline

2、The valve block is the correct movement of the gate, extrusion fast, to ensure effective sealing valve

3、Triangle support material, guarantee the required mechanical properties

4、According to different working conditions demand design V, triangle, or five corners and other ports, in order to meet the needs of various flow regulation

5、No groove at the bottom to make sure no slag and full bore flow

6、The valve strict implementation of the API598 experimental standard, for each product to implement 100% positive and negative double pressure test, guarantee delivery to customers is 100% qualified products

Famous Textile Factory Project in Pakistan

Main products:

flow meters and SS valves

Project description:

This is a relatively special case. Because the customer know less about valves, but the demand is very large. So WESDOM assigns a professional team (salesmen and engineers from the International Trade Department) to conduct on-site inspections and give customer some Pertinent suggestions, and this customer are very shocked and moved by our service, and have established a long-term cooperative relationship with us without hesitation;

Client feedback:

The customer said: “Thank you very much for the on-the-spot inspection and very professional guidance of the WESDOM team.” He was really shocked by the warm and considerate service and professional technical guidance of WESDOM. WESDOM is trustworthy!

Project pictures:

Standard

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.

Application

Stainless steel butterfly valves are also widely used as regulating and intercepting devices on the pipelines of SO2, steam, air, gas, ammonia, CO2 gas, oil, water, brine, lye, seawater, nitric acid, hydrochloric acid, sulphuric acid, phosphoric acid and other media in the chemical, petrochemical, smelting, pharmaceutical and food industries.