Product

Product

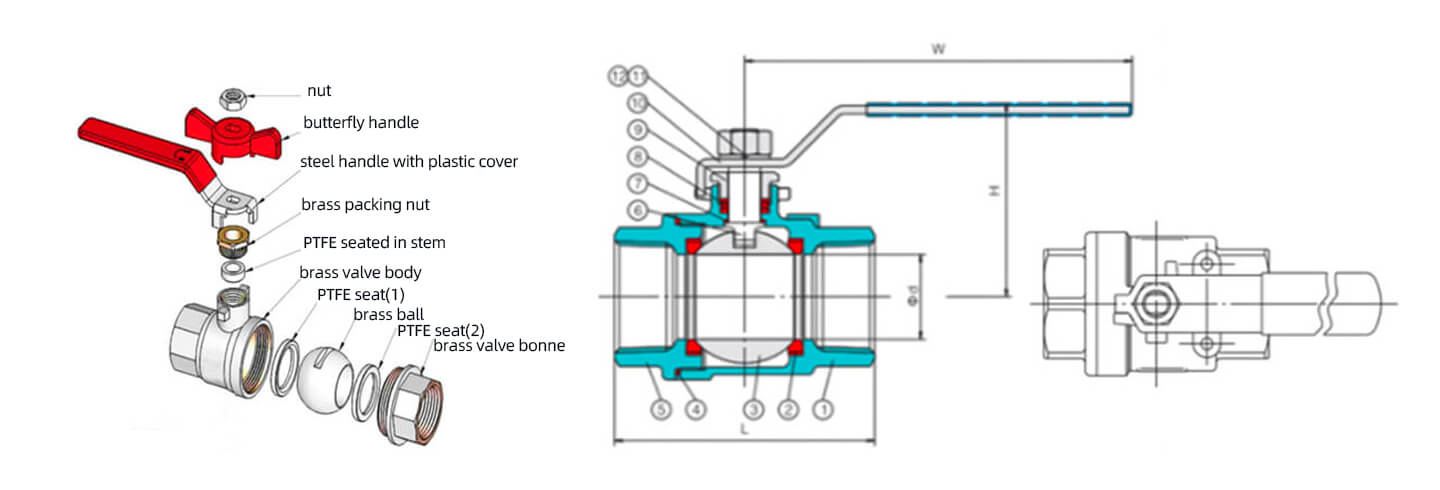

SS Thread Ball Valves

Size: 1/2”~4”

Pressure Rating: 1000WOG

Material: SS304, SS316

Design Standard: API598,GB/T13927,JISB2003

Inspection Standard: Technical data conform to international standard lSO 4064

Application medium: Water, Sewage, Gas

Application Temperature: 0-150℃

Applied projects: Petrochemical, Power plant, Refining, Oil & Gas, Metallurgy etc

The stainless steel two-piece ball valve and the flange gate valve are the same type of valve. The difference is that the closing part is a ball. The ball rotates around the center line of the valve body to achieve opening and closing.

The ball valve is mainly used in the pipeline to cut off, distribute and change the flow direction of the medium. The two-piece ball valve and the three-piece ball valve are a new type of valve widely used in recent years.

The fluid resistance is small, and the resistance coefficient is equal to that of the pipe section of the same length. Simple structure, small size and light weight. It is tight and reliable. At present, the sealing surface materials of ball valves are widely used with plastics and have good sealing performance. It is easy to operate and quick to open and close. It only needs to rotate 90° from fully open to fully closed to facilitate remote control.

The maintenance is convenient, the structure of the ball valve is simple, the sealing ring is generally movable, and the disassembly and replacement are more convenient. When fully open or fully closed, the sealing surfaces of the ball and the valve seat are isolated from the medium. When the medium passes through, it will not cause corrosion of the valve sealing surface.

It has a wide range of applications, from small diameters to a few millimeters to a few meters, from high vacuum to high pressure.

The stainless steel two-piece ball valve can be divided into straight-through type, three-way type and right-angle type according to its channel position. The latter two kinds of ball valves are used to distribute the medium and change the flow direction of the medium.

Feature:

(1)Good sealing performance and small fluid resistance.The sealing surface between the ball and valve is isolated from the media so that the passing medium will not cause its erosion.

(2)Widely used to control and regulate the flow of media such as water, oil and non-flammable gas.The working temperature is -20~200째C, the length is 10.5cm, and the hole diameter is 6.8cm.

(3)With simple structure, small volume and light weight, convenient for maintenance,and it is also suitable for medium with poor working conditions.

(4)The full-bore ball valve has excellent internal thread and durable material. It is made of selected high-quality materials. It is durable and solid.

(5)Simple to operate, with a heavy-duty blue vinyl insulated handle handle that rotates 90 degrees for quick opening and closing. The flow direction of the media is not limited by the direction of installation.

Standard Features:

(1)BSP End Connections

(2)Pipe thread in accordance with ANSI B2.1, BS 21 1973, DIN 259/2999, ISO 228

(3)Blowout Proof Stem / Reduce Port

(4)Investment Casting Body and In-Screw

(5)800 PSI (55 BAR)/1 000 PSI (69 BAR)

Specification:

| Size | 1/2” to 2” (DN15 to DN50) |

| Bore | Full Bore |

| Pressure Rating | 1000PSI / 1000WOG |

| Temperature Range | -20 to 180°C |

| Standard Material | Stainless Steel |

| Seat | PTFE |

Application