Product

Product

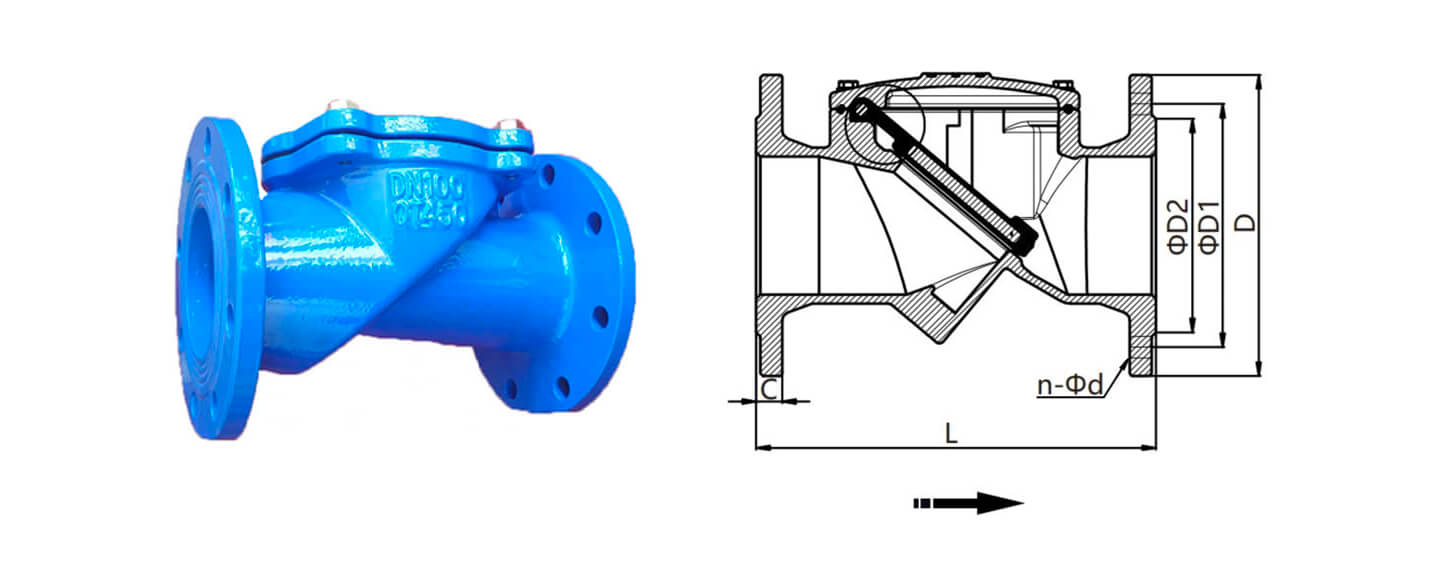

Rubber Seal Check Valve

Size:2”~20”

Pressure Rating:PN10-PN16,150LB,10K

Material:Ductile Iron

Design Standard:BS5153

Inspection Standard:EN12266

Application medium:water

Application Temperature:0-85℃

Applied projects:Hydraulic system

We are professional on valves, fittings and water meters, own 5 factories in China. In addition to valves, pipe fittings and water meters, WESDOM is also committed to the development of piping relating products in order to provide customers with more convenient services. Now WESDOM is not only a valve manufacturer, but also an industrial piping solution provider.

The rubber flap check valve has a complete 100% flow area, low head loss and resistance to clogging. To ensure long-term reliability, because the valve’s reinforced rubber floppy disk is the only moving part, its integral O-ring provides a drop-proof seal under low and high working pressures.

The rubber flap check valve has a unique and simple design with only one moving part. The flap does not swing from the hinge pin; it just flexes open. The seat is at a 45° angle. The baffle moves 35° from opening to closing, usually before column reversal occurs. It has non-slam characteristics.

The valve does not require regular maintenance. At the same time, the combination of 45-degree seat angle, short stroke and the inherent memory of its flexible disc can provide quick closing and anti-impact operation. Recommended for water, sewage, gas, oil and rubber lining chemicals.

Features:

1.Disc 45 Degree design to reduce water hammer;

2.Full rubber coated disc;

3.Horizontal or Vertical installation;

4.FBE coating inside and outside Min 250pm.

5.Due to the inclined design of the sealing ring of the rubber flap check valve, the closing time is short and the water hammer pressure can be reduced.

6.The valve flap is made of nitrile rubber and steel plate after being pressed at high temperature. It is resistant to erosion and has good sealing performance.

7.The product structure is simple, maintenance, repair, transportation is very convenient.

8.It is mainly applied to oil, chemical, food, medicine, textiles, paper making, water supply and drainage, smelting and energy department ,also used as single direction valves.

Standard:

Desing: BS5153

Flanges: BS EN1092-2, ADMEB16.1

Face to Face: EN558-1, DIN F6

Test: BS EN 12266. API 598

Materials:

| Item | Parts | Material |

| 1 | Body | Ductile Iron |

| 2 | Disc | Ductile Iron+EPDM |

| 3 | Stem | SS304 |

| 4 | Bonnet | Ductile Iron |

| 5 | O-ring | NBR |

| 6 | Bolt | SS304 |

| Dimension (mm) | |||

| NPS | DN | L | D |

| 2 | 50 | 203 | 165 |

| 21/2 | 65 | 216 | 185 |

| 3 | 80 | 241 | 200 |

| 4 | 100 | 292 | 220 |

| 5 | 125 | 330 | 250 |

| 6 | 150 | 356 | 285 |

| 8 | 200 | 795 | 340 |

| 10 | 250 | 622 | 405 |

| 12 | 300 | 698 | 460 |

| 14 | 350 | 787 | 520 |

| 16 | 400 | 914 | 580 |

| 18 | 450 | 914 | 640 |

| 20 | 500 | 978 | 705 |

Pakistan Petroleum Project

Main products:

API valves and fittings

Project description:

All valves and fittings were through SGS Inspection.

Client feedback:

WESDOM is a very trustworthy team, not only professional, but also caring and enthusiastic in service. If there is a demand in the future, we will choose WESDOM without hesitation.

Project pictures:

Application