Product

Product

Rubber Joint

Size: 1-1/4”~64”

Pressure Rating: PN10/PN16/PN25

Material: NR/ EPDM/NBR, Flange: Q235,304,316

Design Standard: GB/T26121-2010

Application medium: Water, Oil,Gas

Application Temperature: -15℃--+115℃( -30℃--+250℃ )

Applied projects: Rubber joints are used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire, power and other basic engineering. According to different materials can be made of acid resistance, alkali resistance, corrosion resistance, oil resistance, high temperature resistance, radiation resistance, wear resistance, aging resistance and other varieties, adapt to a variety of media and environment.

Rubber joints are used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire, power and other basic engineering. According to different materials can be made of acid resistance, alkali resistance, corrosion resistance, oil resistance, high temperature resistance, radiation resistance, wear resistance, aging resistance and other varieties, adapt to a variety of media and environment.

The Rubber Expansion Joint has a spherical design that gives it four-way movement. It allows for axial compression and extension, lateral deflection, angular and torsional movement.

Aside from absorbing directional movement, this expansion joint also dampens noise and vibration caused by mechanical equipment. It can be used to correct minor pipe misalignments during installation and relieve pipe stress caused by thermal expansion or mechanical movements.

This rubber expansion joint is suited to transporting fluids, slurries, or gases. Steel reinforcement embedded in grooved rubber ends provides strength under pressure or vacuum. Spherical design distributes internal pressure in all directions, reduces turbulence, and prevents sediment build-up.

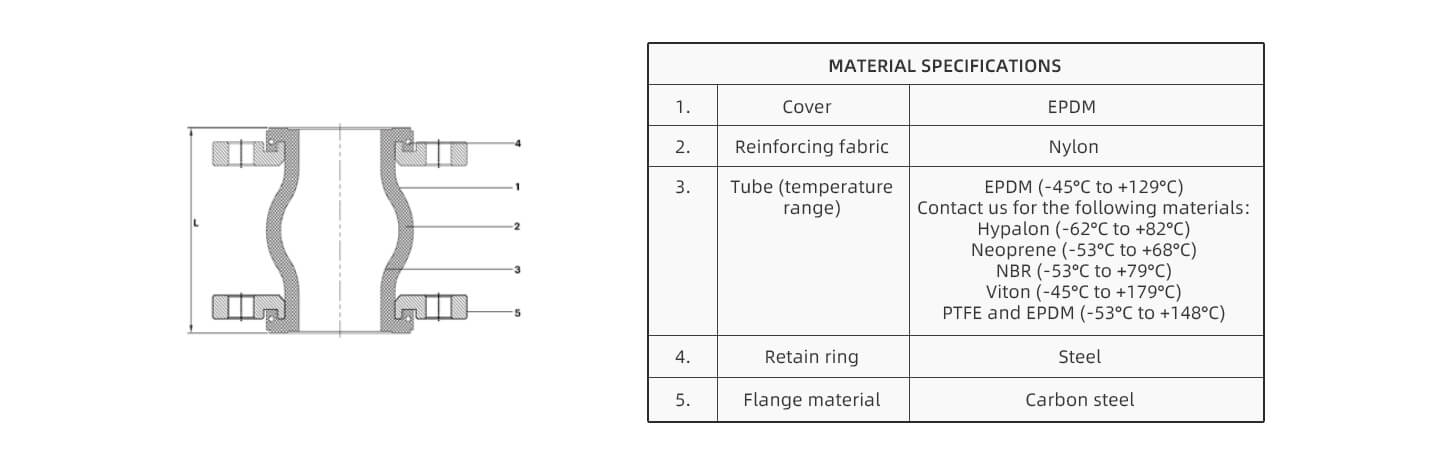

Choose from a range of inner tube and outer lining materials to suit your media and site conditions.

Key features:

(1)The spherical design distributes internal pressure in all directions,

reduces turbulence, and prevents sediment build-up.

(2)Inner tube and outer lining use a wide variety of elastomers to

prevent leakage, provide thermal resistance, and offer protection

from various media.

(3)Steel reinforcement embedded in grooved rubber ends provides

strength under pressure or vacuum.

(4)High strength supporting canvas gives additional pressure resistance.

(5)Floating flanges ensure a reliable seal and are easy to install.

| Technical Specifications | |

| Size range | 1-1/4”~64” |

| Pressure class and

model |

PN10 (E11)

PN16 (E12) PN25 (E13*) *Only for >DN300 and with limit rods |

| End connections

|

DIN PN10, PN16, others flange drilling

as BS EN1092, PN16 AS2129 Table D, E ANSI150 and JIS10K available on request |

| Vacuum

|

660mm Hg*

*Anything higher requires a vacuum spiral or ring |

Our product

Application