Product

Product

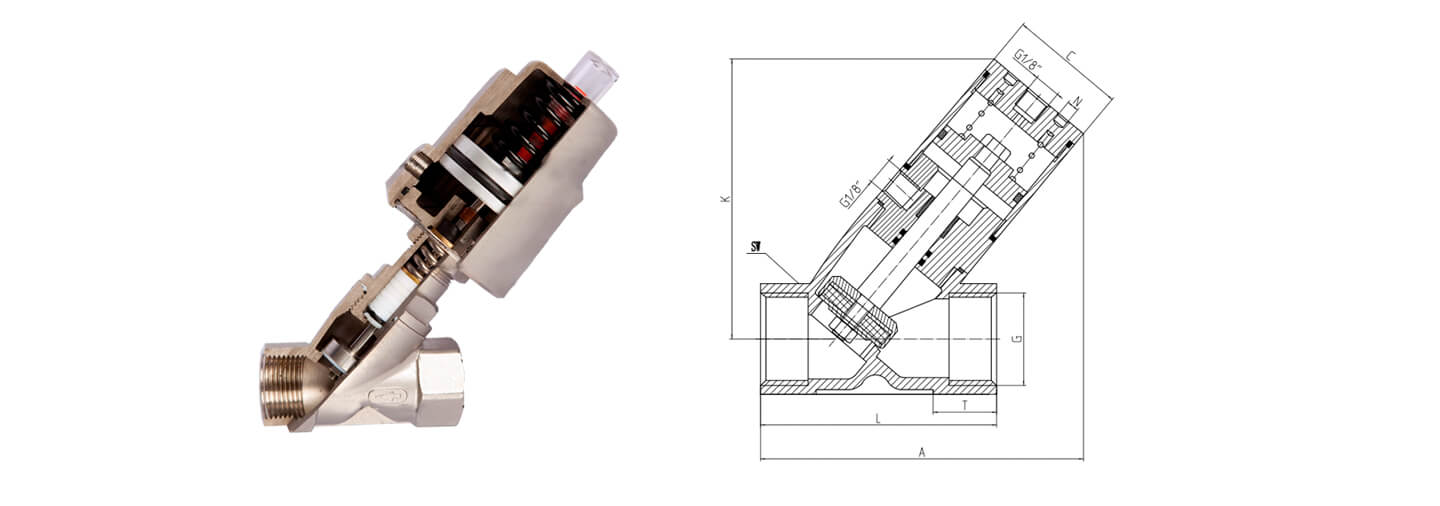

Pneumatic Angle Seat Valve Control valve

Size: 1/2”-2”

Pressure Rating: PN10-PN40,150LB-300LB

Material: Stainless Steel

Design Standard: API6D,ASME B16.34

Inspection Standard: API598

Application medium: water, oil, powder

Application Temperature: 0-200℃

Applied projects: Pneumatic Angle seat valve used in textile printing and dyeing, petrochemical, biological pharmaceutical, cleaning and disinfection, food and beverage and other fields.

Pneumatic angle seat valve is a pilot angle seat valve operated by a single-acting pneumatic actuator with spring safety protection. When in use, normally open or normally closed should be selected. Pneumatic angle seat valve is widely used in short-term frequent start, with the characteristics of sensitive response and accurate action. When used with solenoid valve, the gas and liquid flow can be accurately controlled by pneumatic control. Accurate temperature control, dripping liquid and other requirements can be achieved.

Pneumatic angle seat valve is a common pipeline switch in automatic control system. It is widely used in printing and weaving, printing and dyeing, bleaching, food, washing, chemical industry, water treatment, medicine and other automatic machinery and equipment. It has no water hammer and no noise. , reliable sealing performance and so on.

Product description:

Angle seat valves are 2/2-way pneumatically actuated piston valves. The piston actuator provides a linear motion to lift the seal off its seat. Because the seat is positioned under an angle, the flow is minimally impeded in the open position, resulting in an excellent flow rate and a low pressure loss. They are used to regulate the flow of liquids, gases, steam, vacuum and even aggressive fluids. They can also operate with high temperatures and high viscosity media, even under zero differential pressures.

The robust design makes angle seat valves a popular choice for harsh applications and they have very high cycle lives. Therefore, they are excellent long-life alternatives to ball valves. These valves are also suitable alternatives for solenoid valves, especially with contaminated, viscous media where typical solenoid valves would fail. They may be operated using a single acting or double acting configuration, which has an influence on its pressure rating. They can also be designed as manually operated or electrically operated.

Working principle:

Angle seat valves are operated pneumatically such that air pressure is used to control the piston actuator, which lifts the valve plug off its seat. Normally Closed (NC) valves usually have the valve closed in unpressurized conditions and use a spring to return the valve to the rest state.

Normally Open (NO) valves have the valve opening always open unless air pressure acts to close it. A NO valve can be obtained if the spring is placed on the opposite side of the piston actuator. Double Acting valves can be used to handle flow in both directions. These valves have no spring and depend on the supply air to determine the valve position.

These configurations influence the pressure rating of the valve. Flow up and under the valve (causing valve to open) will reduce water hammer effect but reduces the maximum working pressure of the valve by typically 50%. However, fitting a strong return spring will help increase the working pressure but a larger actuator will be required to overcome this increased spring strength. With flow over seat (causing valve to close), a full working pressure is achieved and water hammer can be reduced by restricting the compressed air supply flow.

Construction and design:

They have a robust construction similar to globe valves, but use a piston operated angle seat valve with a closure spring. The body is normally cast or die-forged in one piece. A plug is connected to the end of the piston which is seated on PTFE seats. The piston is designed to retract further from the seat, thereby providing maximum flow rate. They may be Normally Closed (NC), Normally Open (NO) or Double Acting. The piston actuator comes with threaded ports or with NAMUR ports which allows for direct mounting of NAMUR style solenoid valves.

Often, the actuator head can be rotated 360° to allow optimum position of air and electric lines in tight locations. The valve body is generally made of brass or stainless steel. Connection types include threaded, clamped or welded. Typically, a visual indicator on the top of the piston shows whether the valve is open or closed.

Advantages:

1.Large Flux, low Resistance, No Water-hammer Y-type Shape Enlarged The Flowing Section, which Could Raise The Flux By 30% And Make Flow More Smooth

2.Super Long Life.

3.Which Help The Stem Adjust And Lubricate Itself Automatically.

4.The Cylinder Material is Stainless Steel.Lubricating Automatically,360 Rolling Freely.

Technical data:

Fluid Pressure : Max×1.6MPa(232psi)

Control Pressure:0.3-0.8MPa(43.5-116psi)

Control Fluid:Neutral gas,Air

Actuator Size:27mm,32mm,40mm,50mm,63mm,80mm,100mm,125mm

Applicable Fluid:Water,Alcohol,Oil,Dye,Steam,Neutral gas or liquid,Organic solvent,Acid and lye

Fluid temperature:-10℃-+180℃,25℃-+220℃

Ambient temperature:-10℃-+80℃

Control Type:Normally closed,Normally open,Double acting

Connection: Threaded(BSP.BSPT,NPT),Welded, Flanged, Tri-clamp

Main materials:

Body Material:CF8M(SS316),CF8(SS304)

Seals Material:PTFE

Actuator Material:CF8 (SS304)

Pakistan AL-MORIZE Sugar Factory

Main products:

Control/On-off butterfly valves, Control globe valves, Control ball valves, Angle seat valves.

Project description:

The customer found WESDOM through Google advertisements, because he himself is relatively familiar with valves, so he sent the required products, product materials and required medium to our salesman in the international trade department, and the WESDOM salesman also promptly contacted with our factory’s sales department and the engineering department, and then gave the customer the best price;

Client feedback:

WESDOM’s valves are not only of high quality, but also of very good service and price. At the same time, you can also customize your own logo and color. The delivery time is very punctual. They are very satisfied with the cooperation with WESDOM, and they will choose WESDOM if you need it;

Project pictures:

Application

Beer& Drink Filling Machinery

Textile printing& Dyeing

Gas industry

Pharmacy& Medical Equipment

Chemical industry

Disinfection

Frothing Equipment

Water/sewage Disposal