Product

Product

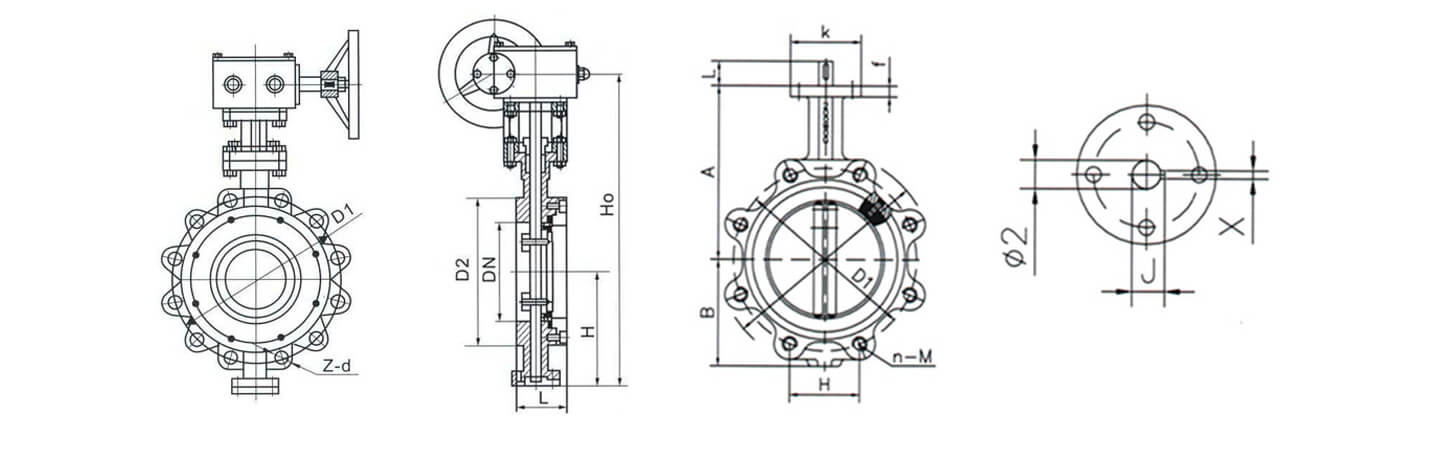

Lug butterfly valve

Size:2”~24”

Pressure Rating:PN10/PN16, 150LB

Material:Cast Iron, Ductile Iron, WCB,Stainless Steel

Design Standard: BS5 155,EN593,API609

Inspection Standard: EN12266, API 598, GB/T 13927-92

Application medium:water

Application Temperature:-10℃~120℃

Applied projects: Petroleum/Electricity/Metallurgy/Water/Sewage/Energy

/Construction

WESDOM could provide various butterfly valves which can be widely applied in all many kind of industrial fluids. The sizes from DN25~DN2400 are all available. The standard we can comply DIN, JIS, GB, API 609, etc. CHOOSE WESOM, CHOOSE QUALITY!

This butterfly valve is a lug type valve with through holes and can be used for many applications. The through holes makes it easy to install or uninstall the valve from the pipeline. The valve can be used as a stopper, a tap for discharging at the end of the pipeline, open/close and flow control. The threaded holes make it easy to install or uninstall from the pipeline. Operation can be manual, pneumatic, hydraulic or electric.

Lug type butterfly valve features:

(1)Simple structure and easy operation

(2)Easy installation and good sealing

(3)Long service life and high reliability

(4)Good interchangeability of parts and cost saving

(5)Wafer type butterfly valve with concentric design

(5)Using backless structure, Rubber fusion bonded on valve body

(6)Replaceable, resilient seat

(7)Streamlined disc, one-piece stem

Lug Type ductile iron butterfly valve Standard:

(1)Design and Manufacture Conform to EN 593, API609, JIS

(2)Flange dimensions Conform to EN 1092-2 PN10, PN16, JIS5K, JIS10K,ANSI B16.1,DIN2501,BS4504

(3)Face to Face dimensions Conform to EN558 series

(4)Top Flange dimensions Conform to ISO5211

(5)Testing Conform to API598、EN12266-1

Lug type butterfly valve Standard Test :

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.

| Design standard | API609, ANSI16.34, JISB2064, GB T12238 |

| Face to Face | API609, DIN3202, ISO5752, BS5155 |

| Flange drilling | DIN2501 PN10/16, ANSI 125/150/300, BS4504, JIS10K |

| Top Flange | ISO5211 |

| Test Inspection | API598 |

Product parameters:

| DN | A | B | L | H | K | D1 | n-M | J | f | X | ø2 |

| 50 | 161 | 80 | 32 | 88.38 | 77 | 125 | 4-M16 | 13.8 | 13 | 3 | 12.6 |

| 65 | 175 | 89 | 32 | 102.54 | 77 | 145 | 4-M16 | 13.8 | 13 | 3 | 12.6 |

| 80 | 181 | 95 | 32 | 61.23 | 77 | 160 | 8-M16 | 13.8 | 13 | 3 | 12.6 |

| 100 | 200 | 114 | 32 | 68.88 | 92 | 180 | 8-M16 | 17.77 | 13 | 5 | 15.77 |

| 125 | 213 | 127 | 32 | 80.36 | 92 | 210 | 8-M16 | 20.92 | 13 | 5 | 18.92 |

| 150 | 226 | 139 | 32 | 91.84 | 92 | 240 | 8-M20 | 20.92 | 13 | 5 | 18.92 |

| 200 | 260 | 175 | 45 | 112.89 | 115 | 295 | 8-M20 | 24.1 | 13 | 5 | 22.1 |

| 250 | 292 | 203 | 45 | 90.59 | 115 | 350 | 12-M20 | 31.45 | 13 | 8 | 29.45 |

| 300 | 337 | 242 | 45 | 103.52 | 140 | 355 | 12-M20 | 34.6 | 20 | 8 | 31.6 |

| 350 | 386 | 267 | 45 | 89.74 | 140 | 400 | 12-M20 | 34.6 | 20 | 8 | 31.6 |

Material:

| Body | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Disc | Ductile Iron, Carbon Steel, Stainless Steel |

| Stem | Stainless Steel |

| Seat | EPDM, NBR, PTFE, VITON, HYPALON |

| O ring | EPDM, NBR |

| Bushing | PTFE, BRONZE |

Installation:

Before installation, clean the inside and outside of the pipe to ensure no sundries; Carefully check whether the use of the valve is consistent with its performance specifications;

Install the valve in time after opening, do not invert; The screw shall be tightened before installation, and the sealing surface shall be completely fitted.

Tanzania Water Project

Main Products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WESDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WESDOM;

Project pictures:

Application

(1)Potable water supply pipelines and treatment plants.

(2)Transportation of filtered and recycled water.

(3)Irrigation distribution networks.

(4)Water-pumping stations and hydroelectric plants.nuclear

(5)Industry, fire safety and storage facilities.