Product

Product

High-Performance Butterfly Valve

Size:2”-60”

Pressure Rating:150LB,300LB

Material:WCB, Stainless Steel

Design Standard: API 609

Inspection Standard: API598

Application medium:Water, Sewage, Gas

Application Temperature: -20℃-150℃

Applied projects:Fast and frequent switching, high temperature and high pressure, vacuum environment

Stainless steel high performance butterfly valve is an innovative double offset design product with advanced world leading technology. This butterfly valve has a unique structure with ultra reliable sealing performance, wide working conditions and low operation torque. The stainless steel material would provide the excellent corrosion resistance performance.

Wafer Type High Performance Double Offset Butterfly Valve;Stainless steel high performance butterfly valve is an innovative double offset design product with advanced world leading technology. This butterfly valve has a unique structure with ultra reliable sealing performance, wide working conditions and low operation torque. The stainless steel material would provide the excellent corrosion resistance performance.

Features & Benefits:

High Pressure, High Temperature, Zero Leakage Butterfly Valves

The high performance butterfly valve (also known as a double offset butterfly valve) features an innovative design that offers rugged reliability and extremely easy maintenance in the field. Independent and internal tests prove the Series McCannalok valve’s superior service life capability, with zero leakage shutoff.

Testing Standard:API 598

Body Style:Wafer, Lug, Double Flanged

Temperature Range:-62°F to 500°F (-52°C to 260°C)

Size Range:NPS 2 to 66 / DN 50 to 1500

Body Materials:Carbon Steel, Stainless Steel, Nickel Aluminum Bronze

Stem Materials:Stainless Steel

Face to Face:API 609, ISO 5752

Applications: High Pressure, High Temperature, Critical Service

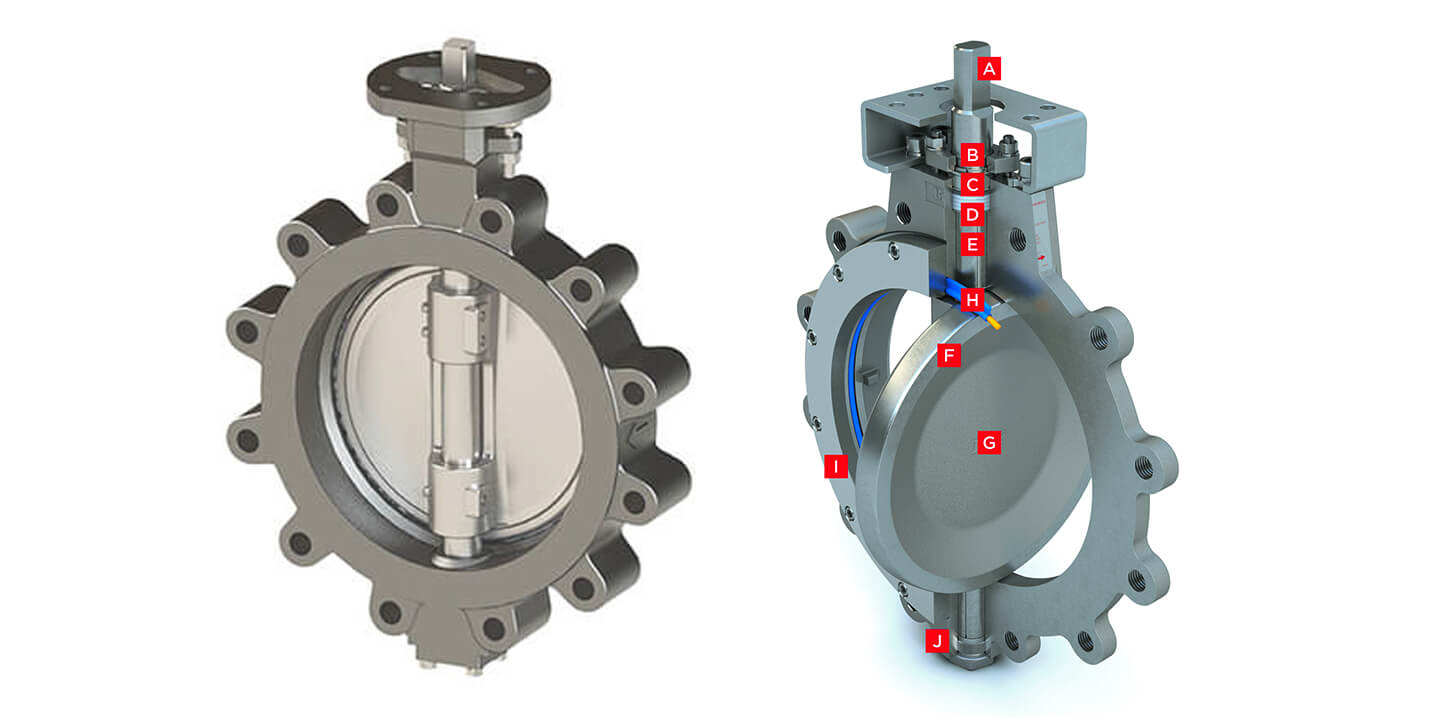

| A. Stem | The high-strength, one piece stem is Stainless Steel. The valve stem is standardized for interchangeability of wesdom actuators. |

| B. Blow-out Proof Stem

|

A retaining ring is installed between the machined stem groove and gland retainer step. |

| C. Adjustable Stem Packing

|

The stem packing system features easy access to adjusting hex head nuts without requiring removal of the actuator. |

| D. Stem Seal

|

The stem seal system provides constant compression for a positive seal around the stem. PTFE packing seals the stem and a carbon fiber anti–extrusion ring contains the packing. Flexible graphite rings are available for high temperature applications and are standard on fire safe valves. |

| E. Stem Bearings

|

Top and bottom bearings, consisting of a 316 Stainless Steel shell with a TFE/glass fabric liner bearing surface securely support the stem. The stem bearings provide excellent resistance to corrosion and distortion from high temperatures and mechanical loading forces. |

| F. Taper Pins

|

Taper pins are precision fit into reamed holes. |

| G. Disc

|

The disc has been engineered to maximize flow and minimize resistance providing a high Cv. Stainless Steel is standard. |

| H. Internal Travel Stop

|

Designed to prevent travel of the disc and minimizing possible seat damage, therefore extending the service life of the seat. |

| I. Resilient Seat

|

Energizer encapsulated in RTFE |

| J. Full-faced Seat Retainer

|

Retainer is firmly attached by bolts located outside of sealing area, protecting the bolts from corrosion. |

| K. Body

|

All body styles offer bi-directional sealing as standard to full ASME Class 150, 300 or 600 ratings. Extended neck allows for 2″ of pipeline insulation and easy access to stem packing adjustments and actuator mounting. |

| Name | stainless steel high performance butterfly valves |

| Design | API 609/ASME B16.34 |

| End Connection | Wafer/Lug/Double flanged |

| Operation | Manual/Pneumatic/Electric |

| Size Range | NPS 2″-60″(DN50-DN1500) |

| Pressure Rating | ASME Class150-300-600(PN16-PN25-PN40) |

| Body Material | Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel |

| Seat Material | PTFE, RPTFE, PPL |

| Temperature | -29℃ to 250℃ |

| Brand | WESDOM |

| WESDOM is a leading quality high performance butterfly valve manufacturer. | |

Application