Product

Product

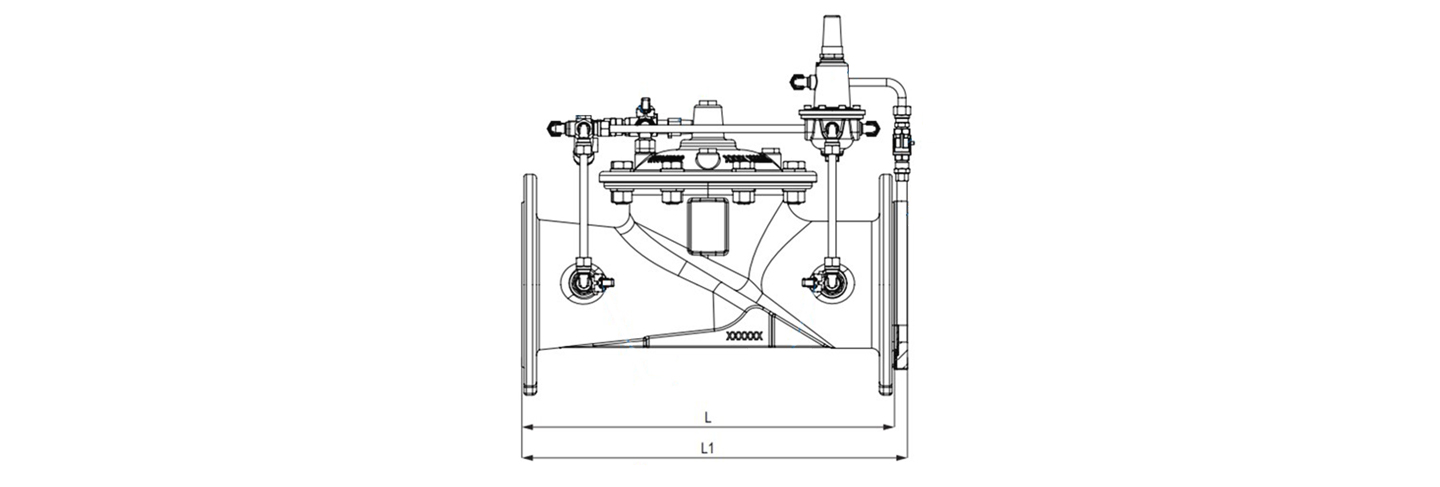

Flow control valve

Flange standard:EN1092-2, BS4504

Valve Test:EN12266

Face to Face Length: BS EN558

Inspection Standard:EN13709-2002

Application medium:Water

Application Temperature:<=80℃

Applied projects:Water conservancy construction

The piston type multi -function pump control system is the intelligent valve installed in the outlet of the pump outlet of the large-caliber water supply pipe network, preventing the backflow of the medium, waiter hammer and water hammer. The valve has three functions of electric valve, reverse stop valve and water hammer eliminator, which can effectively improve the safety and ability of the water supply system. Double Chambers and double disc structure can make the valve after the pump stopped quickly closed90% (to prevent the back flow medium pump inversion), and then aiowly Closing the remaining 10% (eliminate destructive water hammer) piston valve ls reliable In performance, high strength, smooth movement, prevent pumping water hammer and 8top the pump water hammer, The valve can automatically realize the opening and closing according to the operating procedures of the pump motor, and the discharge volume and pressure loss are small.

Rate of Flow Control Valves prevent excessive flow by limiting flow to a preselected maximum rate, regardless of changing line pressure. They are hydraulically operated, pilot controlled, diaphragm valves. The pilot control responds to the differential pressure produced across an orifice plate installed downstream of the valve. Accurate control is assured as very small changes in the controlling differential pressure produce immediate corrective action of the main valve. Flow rate adjustments are made by turning an adjusting screw on the pilot control.

A typical application for this type of automatic control valve is as a pressure type filter effluent control valve where a constant flow rate is maintained despite variation in head loss through the filter, or anywhere a constant rate of flow is desired.

Control valve, constant flow, for drinking water or other neutral liquids to max. 70°C. The series offer two ranges, reduced bore and full bore. The full bore has increased capacity compared to reduced bore.

Features:

(1)The lifted seat design controls the flow around the plug so that in case of cavitation this happens with minimal damage away from plug and seat

(2)The parabolic shape of the plug creates a smooth regulating characteristic with low gain around the near-closed positions improving control performance at low flow

(3)Non-symmetric axial position of rubber diaphragm results in low stretch stress when closed

(4)Body and bonnet of ductile iron coated with fusion bonded epoxy

(5)All rubber parts approved for drinking water

(6)All non-coated internals made of stainless steel or bronze

(7)Seat and pilot in stainless steel AISI 304

(8)A needle valve fitted between the upstream side and the control chamber allows for adjustment of the regulation reaction time

(9)Closing the needle valve isolates the control chamber and fixes the position of the main valve allowing for service of the pilot valve

(10)Fittings, pipes and accessories in Ni-plated brass

Test/Approvals:

Hydraulic test: 1.5 x PN |

Tested according to EN12266-1. Seat: 1.1 x PN (in Bar), Body: 1.5 x PN (in Bar)

WRAS approved Materials

Standards:

Designed according to EN 1074 – 5

Face to face according to EN558 Table 2 Basic Series 1

Standard flange drilling to EN1092 (ISO 7005-2), PN 10/16

Technical Request:

(1)Inspection: EN13709-2002

(2)Face to Face Length: BS EN558

(3)Valve Test: EN12266

(4)Flange standard: EN1092-2, BS4504

Application