Product

Product

Float valve

Flange standard:EN1092-2, BS4504

Valve Test:EN12266

Face to Face Length: BS EN558

Inspection Standard:EN13709-2002

Application medium:Water

Application Temperature:≤80℃

Applied projects:Water conservancy construction

The piston type multi -function pump control system Is the intellient valve installed In the outlet of the pump outlet of the large- -caliber water supply pipe network, preventing the backflow of the medium, waiter hammer and water hammer, The valve has three functions of electric valve, reverse stop valve and water hammer eliminator,which can effectively improve the safety and ability of water supply system.

Double Chambers and double disc structure can make the valve after the pump stopped quickly closed90% (to prevent the back flow medium pump inversion), and then aiowly Closing the remaining 10% (eliminate destructive water hammer) piston valve ls reliable In performance, high strength, smooth movement, prevent pumping water hammer and 8top the pump water hammer, The valve can automatically realize the opening and closing according to the operating procedures of the pump motor, and the discharge volume and pressure loss are small.

What is a float valve?

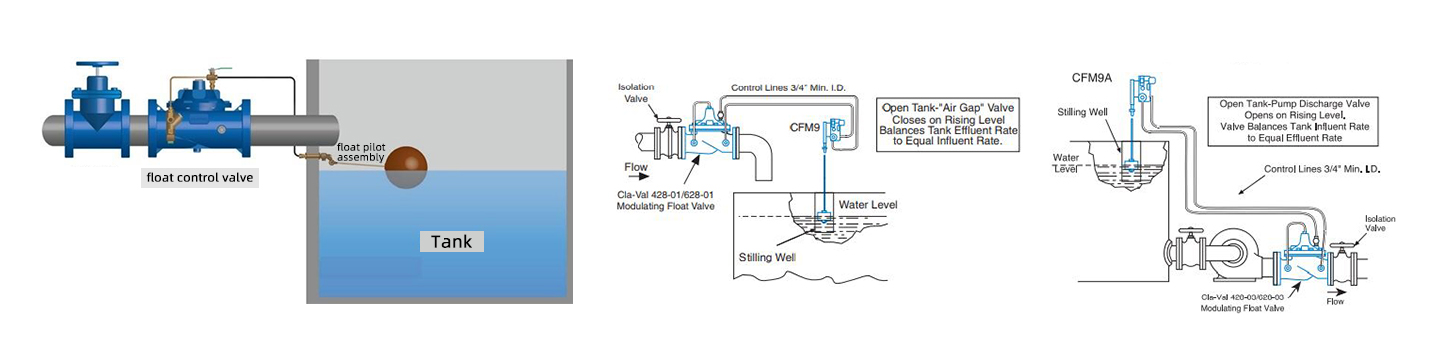

A float monitors changes in the liquid free surface’s height and opens or closes a valve in response. In-home water systems, a large number of small float valves are used. The level in the cold water header tank is maintained by a float valve, which controls the pressure in the hot water system.

What is a float valve and what does it do?

This valve can be used to manage the amount of water in a tank, and it can open and close as the liquid level changes. This valve is mechanically operated by a float. These are liquid level control valves, which are commonly seen in industrial refrigeration systems. The float valves are employed as a throttling device in large refrigeration systems. Float valves are actuated lever valves used to control the level of liquids in a tank.

Function of a float valve:

Float valves are utilized in a variety of industrial applications and can be used in conjunction with other valves. The liquid level measured by the float causes the float valves to open and close. A hollow metal or plastic ball could be used as the float. The employment of a float valve in flow pressure-lowering valves is an example of float valve action. The float valve can control the main valve by utilizing a sub-valve. The sub valve would set a water level in the tank, and if the water level rose over that level, it would close, allowing the main valve’s back pressure chamber to rapidly handle the pressure. As a result, in major industrial plants, the float valve can be utilized to manage the water level.

Product advantages:

(1)Accurate Level Control

(2)Completely Automatic Operation

(3)Simple Operation

(4)Easy Installation and Maintenance

Optional Features:

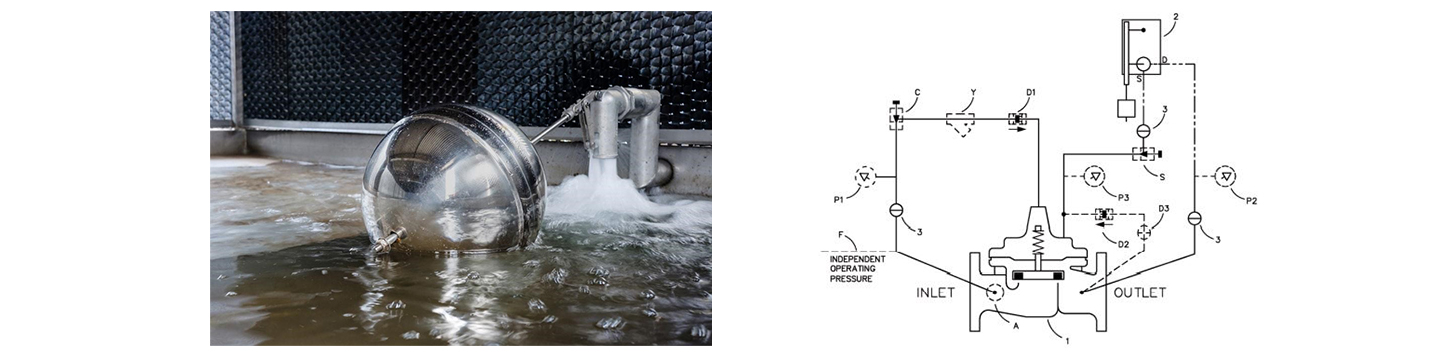

Item Description

A X46A Flow Clean Strainer

D Check Valves with Isolation Valve

C CV Speed Control

F Independent Operating Pressure

P X141 Pressure Gauge

S CV Speed Control

Y X43 “Y” Strainer

What’s in the float valve?

The valve is made up of a horizontally sliding cylinder. The chamber of the float lever forces it against the water intake in the closed position, blocking the water flow. The piston leaves the gate when the float drops, allowing the water to flow.

Flow valve against float switch:

In the toilet, you’ll find an air-filled balloon connected to a bar, which is connected to a filling valve. The float lowers below the water level when you unload, the rod opens the filling valve, and water begins to flow towards the tank. When the stem closes the valve and the water stops, the float rises to a certain extent with the water. This is an example of a float valve in action.

The float switch works on the same concept as the valve, but instead of activating the valve, it triggers a switch that runs the pump. The pump may be used to fill the reservoir (as in some well systems) or to drain the well (as in a discharge pump). The switch in the sump system is turned on to start the pump and does not turn off when the water level rises.

Technical Request:

(1)Inspection: EN13709-2002

(2)Face to Face Length: BS EN558

(3)Valve Test: EN12266

(4)Flange standard: EN1092-2, BS4504

There are several important variables to consider when selecting a float valve, such as:

(1)According to the size of the valve

(2)Media

(3)Connections

(4)Maximum operating pressure

(5)Globe or angle pattern

(6)Maximum temperature

(7)The discharge pressure of the valve if other than the atmosphere

Float valve installation:

The float valve must be installed horizontally; it cannot be installed vertically to discharge water. In order to perform thorough maintenance, an isolation valve should be fitted before the automatic float control valve so that the pipe system can be drained. The installation of the float valve should only be done by a professional.

If you want to install the float valve properly, follow this guide step by step:

First, remove the bulkhead fitting from the tank when installation. Then, install the valve assembly after removing the drain stopper. When placing float valves in water tanks, the float should be placed at the surface of the water, where it will be least affected by the waves. The discharge pipes would prevent the waves from forming. The stem of the valve must be vertical to avoid friction on the inner valve slipping.

Applications of a float valve:

These valves are used in water tanks and cisterns to keep the water level consistent and avoid overflow.

The water’s flow is regulated by the ball’s rise and fall.

Low pressure, high pressure, and medium pressure applications are all suitable for these valves.

In big industrial refrigeration systems, it is employed as a throttling device.

Other main applications of a float valve are:

(1)Condensate tanks

(2)Water heaters

(3)Sprinkler services

(4)Reservoirs

(5)Cooling tower

(6)Swimming pools

(7)Open or closed storage tanks

(8)Selection of a Float Valve

Application