Product

Product

Flange butterfly valve

Size:2”~56”

Pressure Rating:PN10, PN16, CL150

Material:Ductile Iron, WCB, Stainless Steel

Design Standard: BS 5155,EN593, API 609,

Inspection Standard: EN12266, API 598,GB/T 13927-92

Application medium:water, oWater, Sewage, Gas

Application Temperature:-10℃~150℃NBR0-70℃,EPDM0-120'℃,PTFE 0-150℃

Applied projects: Petroleum/Electricity/Metallurgy/Water/Sewage/Energy

/Construction

A flanged butterfly valve is a valve with flanges at the inlet and outlets sides. The flanges have holes used to secure bolts when connecting the valve to the pipe. A gasket is placed between the valve and pipe to enhance a tight seal.These valves operate by turning the disc for a quarter turn to start and stop fluid flow. The operation of the valve can be manual or it can be done using valve actuators. Butterfly valve flange types are stronger when compared to other types of butterfly valves.

The range of WESDOM valves can be used for overground installation, in valve chambers and buried systems.

Advantages of flanged butterfly valves :

①These valves can be operated manually or automatically.

②Butterfly valve flange types are small in size and light in weight compared to gate valve, check valve and globe valve.

③They are of compact and simple design.

④These valves can be used in both high-pressure and high-temperature applications depending on the valve seat material.

⑤Flanged butterfly valves are free from fluid leakage.

⑥They can be installed where space is limited, unlike other large-sized valves.

⑦These valves are used in shut-off and throttling fluid flow applications.

⑧These valves operate by making a quarter turn which makes their operations very fast.

⑨Flanged butterfly valves are easy to install, clean, and repair.

Troubleshooting flanged butterfly valves:

1)Valve is hard to operate

①Clogged materials inside the valve. Open the valve and remove such materials.

②Corroded internal parts. Open the valve and clean off any corrosion.

2)Internal fluid leakage

①Damaged seats. Replace the valve seats.

②Worn out O-rings. Replace the O-rings.

③Dirt in the valve. Open the valve and clean the dirt.

3)External fluid leakage

①High fluid pressure. Ensure the valve is working at the pressure level recommended by the flange butterfly valve manufacturer.

②Loose bolts. Tighten the bolts to the torque required by the flanged butterfly valve manufacturer.

③Worn out gasket. Replace the gasket.

④Worn out packing. Replace the packing.

Test/Approvals:

(1)Tested according to EN 12266.

(2)WRAS approved materials

Standards:

(1)EN 593

(2)Face-to-face dimension according to EN 558 Table 2 Basic Series 13

(3)Flange drilling to EN1092, PN10/16

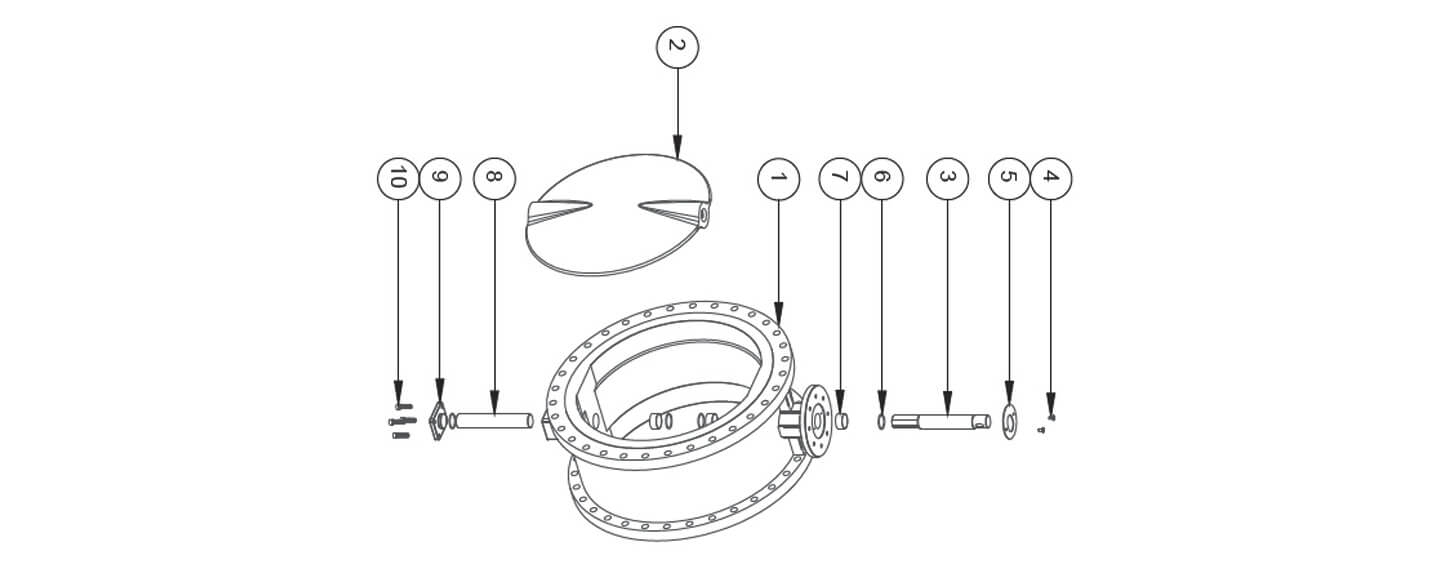

| NO. | Part name | Material |

| 1 | Body | ASTM A536 65-45-12, WCB, CF8M Bonded with NBR or EPDM |

| 2 | Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

| 3 | Stem | SS420,SS431 |

| 4 | Screw | SS304 |

| 5 | Retainer | SS201 |

| 6 | Weather seal | NBR |

| 7 | Bearing | RPTFE with Graphite on I.D. |

| 8 | Lower Stem | SS420, SS431 |

| 9 | Bottom cover | Same as body |

| 10 | Bolt | SS304 |

| 11 | Screw | SS304 |

| DN | L | L1 | D | D1 | D3 | D4 | H1 | H2 | H3 | b | Z-ød | |||

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | |||||||||

| 50 | 108 | 160 | 165 | 1665 | 125 | 125 | 70 | 50 | 83 | 130 | 60 | 18 | 4–18 | 4–18 |

| 65 | 112 | 160 | 186 | 185 | 145 | 145 | 70 | 50 | 93 | 140 | 60 | 18 | 4–18 | 4–18 |

| 80 | 114 | 160 | 200 | 200 | 160 | 160 | 70 | 50 | 100 | 150 | 60 | 20 | 8–18 | 8–18 |

| 100 | 127 | 160 | 220 | 220 | 180 | 180 | 90 | 70 | 110 | 165 | 60 | 20 | 8–18 | 8–18 |

| 125 | 140 | 160 | 250 | 250 | 210 | 210 | 90 | 70 | 123 | 180 | 60 | 22 | 8–18 | 8–18 |

| 150 | 140 | 160 | 285 | 285 | 240 | 240 | 90 | 70 | 143 | 200 | 60 | 22 | 8–22 | 8–22 |

| 200 | 152 | 210 | 340 | 340 | 295 | 295 | 125 | 125 | 171 | 230 | 72 | 24 | 8–22 | 12–22 |

| 50 | 165 | 210 | 390 | 405 | 350 | 355 | 125 | 125 | 203 | 270 | 72 | 24 | 12–22 | 12–26 |

| 300 | 178 | 210 | 440 | 460 | 400 | 410 | 150 | 140 | 230 | 320 | 75 | 26 | 12–22 | 12–26 |

| 350 | 190 | 210 | 50 | 520 | 460 | 470 | 150 | 140 | 260 | 350 | 75 | 26 | 16–22 | 16–26 |

| 400 | 216 | 320 | 565 | 580 | 515 | 525 | 175 | 165 | 300 | 390 | 126 | 28 | 16–26 | 16–30 |

| 450 | 222 | 320 | 615 | 640 | 565 | 585 | 175 | 165 | 335 | 428 | 126 | 30 | 20–26 | 20–30 |

| 500 | 229 | 320 | 670 | 715 | 620 | 650 | 210 | 254 | 373 | 450 | 126 | 32 | 20–26 | 20–33 |

| 600 | 267 | 340 | 780 | 840 | 725 | 770 | 210 | 254 | 430 | 520 | 127 | 34 | 20–30 | 20–36 |

| 700 | 292 | 380 | 895 | 910 | 840 | 840 | 300 | 254 | 470 | 600 | 167 | 36 | 24–30 | 24–36 |

| 800 | 318 | 380 | 1015 | 1025 | 950 | 950 | 300 | 254 | 523 | 662 | 167 | 36 | 24–30 | 24–39 |

| 900 | 330 | 400 | 1115 | 1125 | 1050 | 1050 | 300 | 254 | 589 | 710 | 193 | 40 | 28–33 | 28–39 |

| 1000 | 410 | 400 | 1230 | 1255 | 116 | 1170 | 300 | 254 | 656 | 780 | 193 | 42 | 28–36 | 28–42 |

| 1200 | 471 | 440 | 1405 | 1485 | 1340 | 1390 | 300 | 254 | 732 | 840 | 205 | 46 | 32–37 | 32–49 |

| 1400 | 530 | 440 | 1630 | 1685 | 1560 | 1590 | 300 | 254 | 840 | 905 | 212 | 50 | 36–37 | 36–49 |

Project Name: Pakistan Sewage Treatment Plant Project

Customer name: a customer in Pakistan

Products to Buy: Flanged Butterfly Valves and Gate Valves

Customer demand: the use of sewage treatment plant projects

Engineering Content:

This case is an old customer from Pakistan. Because he has purchased valve products from WESDOM many times, he has very high trust and evaluation on WESDOM. He needs a lot of butterfly valves and gate valve products in the sewage treatment plant project which he is responsible for. They sent the requirements to the businessman of WESDOM’s international trade department without hesitation. Of course, WESDOM still returns this old customer in Pakistan with high-quality products and preferential prices;

After that, the customer also sent us the installation pictures of the WESDOM product in the working condition project, and feedback that the quality is still very good, and will maintain a long-term cooperative relationship with WESDOM;

Project pictures:

Application

①Flanged butterfly valves are used in steam power plants.

②They are used in mining.

③Butterfly valves flange type is used in food and beverage processing plants because they are easy to clean.

④These valves are also used in the manufacturing of pharmaceutical products since they can be cleaned to enhance high levels of hygiene.

⑤They are used in municipal water supply and wastewater treatment.

⑥They are used in fire protection.

⑦They are used in the manufacturing of paper and pulp.

⑧They are used in the refinery of petroleum products.

⑨Butterfly valve flange type is used in the manufacturing of different chemicals.

⑩SS butterfly valves are used in HVAC systems.