Product

Product

Electromagnetic Water Meter

Size: DN50~DN300

Pressure Rating: 1.6MPa(Special customizable)

Material: Carbon Steel/Stainless Steel

Design Standard: GB/T778-2018/ JJG162-2009

Application medium: Clean Water

Application Temperature: -10℃~+75℃

Applied projects: Water Treatment

Advantages of electromagnetic water meter:

Electromagnetic water meter fault maintenance:

LXE series electromagnetic water meter is a kind of instrument for measuring the volume flow of conductive liquid based on Faraday’s principle of electromagnetic induction. It has the characteristics of wide range, low initial flow, low pressure loss, real-time measurement, cumulative measurement, Bi-direction measurement, etc. It mainly uses DMA zoning, online monitoring, water loss analysis and statistical settlement of water supply mains.

The product complies with national standards GB/T778-2018 “Drinking Cold Water Meter and Hot Water Meter”, JJG162-2009 “Cold Water Meter”.

Electromagnetic water meter features:

* No blocking parts inside of measuring tube, low pressure loss and low requirements for straight pipeline.

* Variable diameter design, improve measurement accuracy and sensitivity, reduce excitation power consumption.

* Select suitable electrodes and liner, with good corrosion resistance and wear resistance.

* Full electronic design, strong anti-interference ability, reliable measurement, high accuracy, wide flow range.

* Microprocessor technology, fast calculation speed, high precision, low frequency rectangular wave excitation, adjustable excitation frequency, low power consumption design.

* SMT component placement technology, the circuit is stable and reliable.

* Converter high-definition LCD backlight display, easy to learn and operate.

* Communication:RS485/Bluetooth/LORA/NBIOT etc.

* Protocol: CJT188 protocol or MODBUS protocol.

* With self-diagnosis and self-monitoring functions

* All stainless steel case and infrared remote control operation, protection grade IP68

* High-capacity lithium battery pack, the continuous working time of the measuring part is not less than 10 years

* Reserved external power supply interface, pressure/temperature sensing interface

* Wireless transmission part, battery replaceable designn

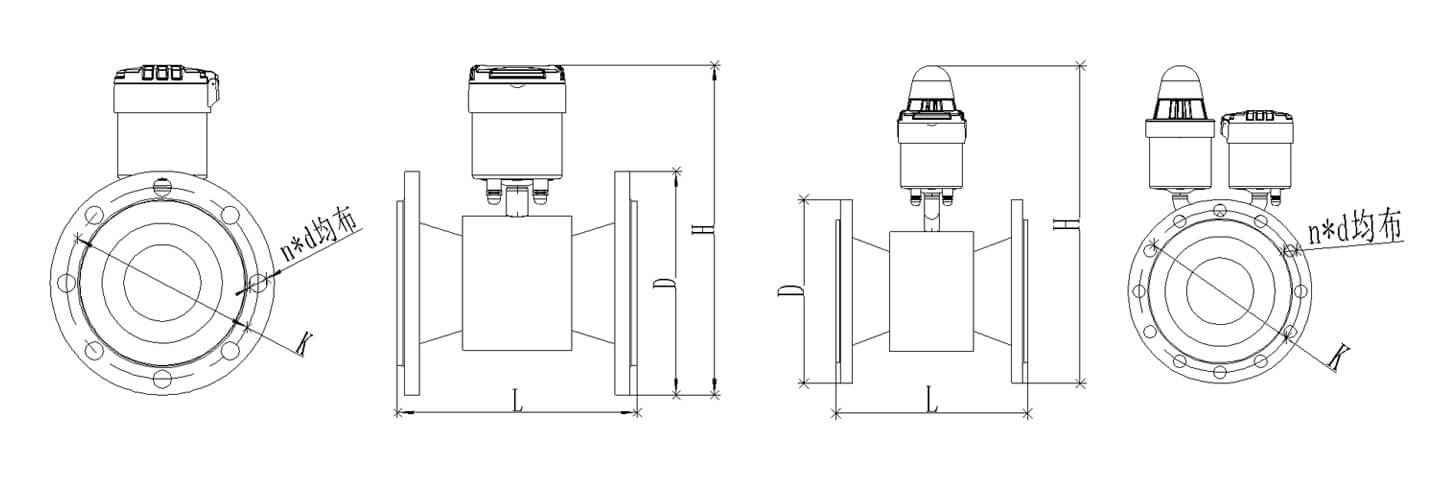

Dimension

| Size(mm) | Nominal flow rate(m3/h) | Range ratio (R) | L(mm) | D(mm) | H(mm) | K(mm) | n*d(mm) |

| 50 | 40 | 400 | 200 | 165 | 328 | 125 | 4*Φ19 |

| 270 | 410 | ||||||

| 65 | 63 | 400 | 200 | 185 | 340 | 145 | 4*Φ19 |

| 270 | 420 | ||||||

| 80 | 100 | 400 | 200 | 200 | 355 | 160 | 8*Φ19 |

| 270 | 436 | ||||||

| 100 | 160 | 400 | 250 | 220 | 365 | 180 | 8*Φ19 |

| 270 | 446 | ||||||

| 125 | 250 | 400 | 250 | 250 | 370 | 210 | 8*Φ19 |

| 270 | 452 | ||||||

| 150 | 400 | 400 | 300 | 285 | 413 | 240 | 8*Φ23 |

| 478 | |||||||

| 200 | 630 | 400 | 350 | 340 | 498 | 295 | 12*Φ23 |

| 580 | |||||||

| 250 | 1000 | 400 | 450 | 405 | 530 | 355 | 12*Φ23 |

| 614 | |||||||

| 300 | 1600 | 400 | 500 | 460 | 588 | 410 | 12*Φ23 |

| 670 |

The Philippines – Water Treatment Plant Project

Main product:

Flange water meter – LXXG model, cast iron water meter FOR irrigation

In the end, WESDOM reached cooperation with this client from the Philippines. By the way,he also purchased some other valves from WESDOM. After receiving the products, they expressed full of praises for the look and quality of the product.

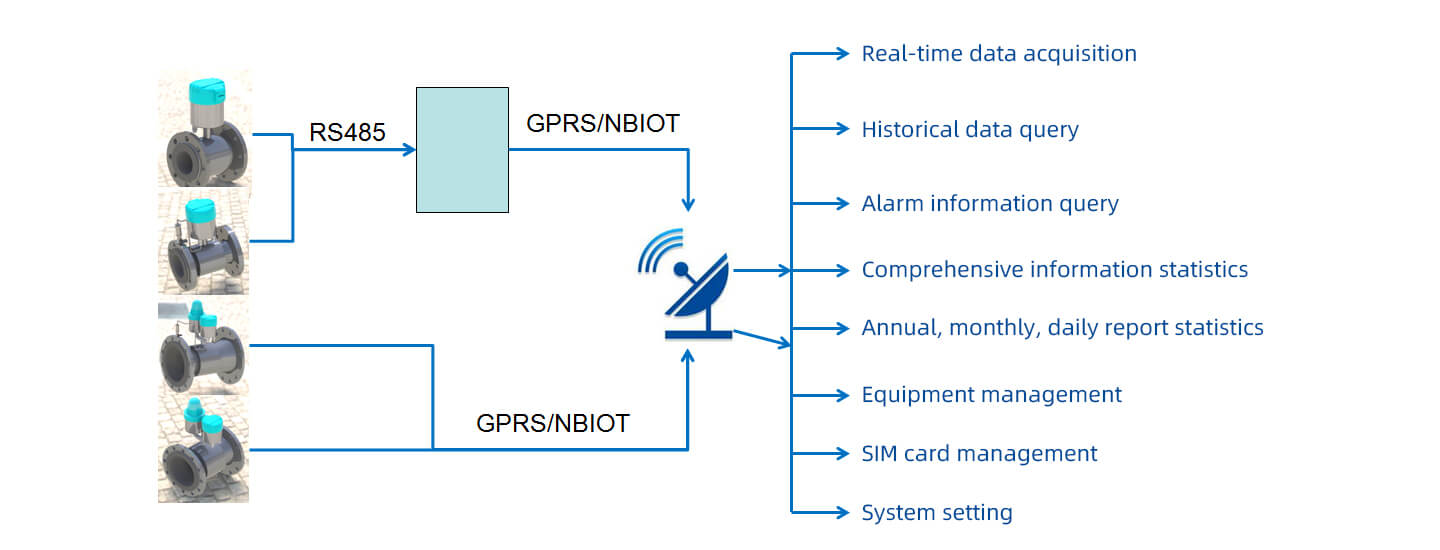

Advantages of electromagnetic water meter:

Big data platform based on NBIOT and GPRS wireless transmission technology, based on B/S architecture. Users can stay at home, in any occasion, any region through the computer or mobile terminal access to the platform, real-time online information monitoring, DMA leakage monitoring, working status monitoring, etc.

* Small table large flow:

For users with a long service life, due to the small pipeline design before, there is a situation of small meter and large flow after the pipe network transformation;

The long-term operation of traditional mechanical water meters will cause large negative deviation due to serious wear and tear, and bring large water loss to the water supply department;

LXE series electromagnetic water meter through structure, no moving mechanical parts, will not cause error due to wear, high measurement accuracy;

* Large table small flow:

Special users (such as swimming pools, etc.), the water consumption is large in less time, and the water consumption is usually small, there is a situation of large surface and small flow;

Mechanical water meter due to the high starting flow, the negative deviation below Q1 is large, the water supply department brings a large water loss;

LXE electromagnetic water meter has a very low starting flow rate (5mm/s), and can basically maintain good measurement accuracy below Q1.

* High water tolerance:

Traditional mechanical water meters often have problems such as stuck, mechanism wear and so on when used in water supply network;

LXE series electromagnetic water meter, the internal structure is straight through, any impurities can pass through, there is no card meter phenomenon;

LXE series electromagnetic water meter, no mechanism wear problem;

* Reduce the difference between production and sales and reduce the cost of table change:

The mechanical water meter has been running for a long time, and the mechanism is worn, which leads to negative measurement. Therefore, the mechanical water meter must be replaced regularly to ensure high precision measurement, otherwise it will increase the difference between production and sales of users.

LXE series electromagnetic water meter through structure, no mechanism wear, can greatly reduce the production and marketing of water supply users.

LXE series electromagnetic water meter, made of 304 stainless steel, very long service life, only regular verification, no need to change the meter.

Electromagnetic water meter fault maintenance:

Fault Symptom 1:

No display

Cause of failure:

The battery is dead.

Solution:

① Connect the standby power supply port

② Notify the manufacturer to maintain

Fault Symptom 2:

Inaccurate flow measurement

Cause of failure:

① Measure whether the liquid is full

② Whether the parameter Settings are correct

③ Whether the zero point is correct

④ Environmental disturbance

⑤ Bubbles in the pipeline

Solution:

① Check the liquid filling in the pipeline

② Check instrument parameters

③ Readjust the zero point

④ Eliminate interference (such as grounding)

⑤ Add exhaust valve

Fault Symptom 3:

Air traffic control alarm

Cause of failure:

① The pipeline is filled with liquid

② The ATC alarm threshold is improperly set

Solution:

① Open the interceptor and fill the piping system

② Adjust ATC alarm threshold and ATC adjustment coefficient

Fault Symptom 4:

The measured flow is opposite to the actual flow

Cause of failure:

The direction of the liquid flow is opposite to the direction of the sensor flow arrow

Solution:

① Check whether the instrument installation direction is consistent with the sensor direction;

② In special cases, the direction can be changed through the program

Fault Symptom 5:

No signal output

Cause of failure:

① No parameter is set or an error is set

(2) The Internet of Things card is not paid

③ Signal strength is too low

Solution:

① Check whether the output parameters of the remote transmission module are correct

② Check the working status of the iot card and the communication balance

③ Check the antenna signal strength, the signal is not less than 15