Product

Product

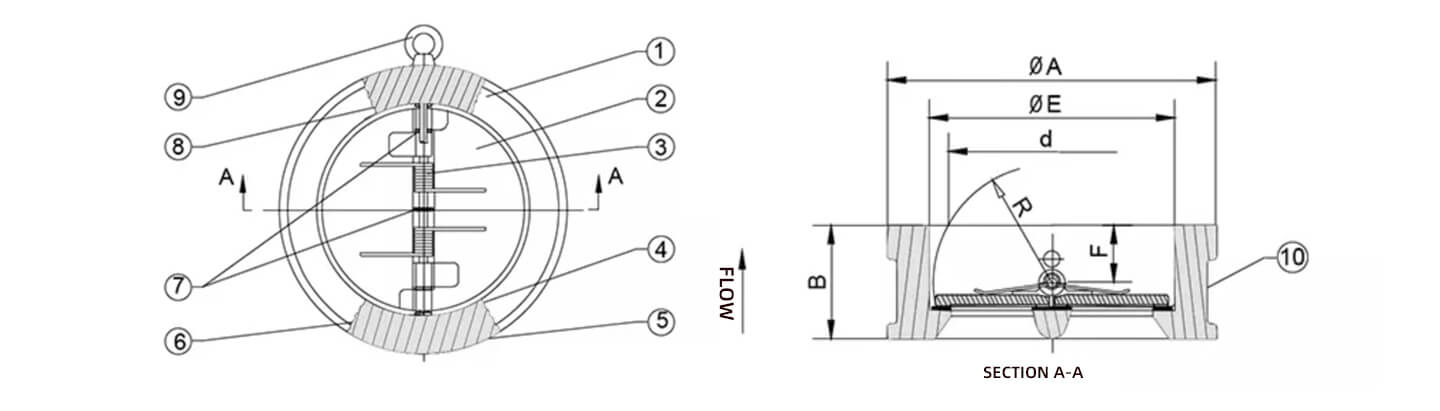

Dual Plate Check Valve

Size: 1-1/2”~20”

Pressure Rating: PN10/16,150LB,10K

Material: Gray iron, Ductile Iron, WCB, Stainless Steel

Design Standard: API594

Inspection Standard: EN12266, API 598,JISB2003

Application medium: Clean Water, Sewage

Application Temperature: -5℃~85℃

Applied projects: Chemicals, air, water, steam, oil, acids, salts ect

The dual plate check valve is a general purpose check valve that is stronger, lighter in weight and smaller in size than traditional swing check valves.

The dual plate check valve utilizes two spring-loaded plates attached to a central dumpling chain pin. When the flow is reduced, the plates are closed by the action of the torsion spring, and there is no need for reverse flow.

This design provides the dual advantages of no water hammer and no impact at the same time.

Consisting of 2 discs attached to the valve body by a pin and operated by the action of springs, which immediately start closing the valve, when the fluid stops, dual plate check valves are used to prevent back flow and also work as a prevention for water hammer.

Dual Plate Check Valves are made from a wide range materials including cast iron, special stainless steels, ect. They can be soft seat or metal seat construction and also have the ability to adjust the spring torque according to the application, which makes it a product suitable for general and special purposes.

Features:

(1)Lightweight, so easier to handle and self-supporting. More compact and well-structured design.

(2)The same valve can be installed horizontally or vertically.

(3)Due to the spring assisted closing, only the double plate check valve can be installed upside down.

(4)Reduced pressure drop and energy loss regardless of pressure rating.

(5)Efficient and reliable sealing under most flow and pressure conditions.

(6)The valve closes before the flow reverses and the velocity is zero.

(7)Water hammer is almost non-existent.

(8)Long service life and trouble-free operation.

(9)Small in size, light in weight, compact in structure,easy in maintenance.

(10)Two torsion springs are used excreting on each of the pair valve plates,which close the plates quickly and automatically.

(11)The quick-close action prevents the medium from flowing back and eliminates water hammer effect.

(12)Short body structure length and good rigidity.

(13)This valve is tightly sealed, without leakage under the pressure water test.

(14)Safe and reliable in operation,high interference-resistance.

Specifications:

| Nominal pressue (MPa) | 1.0 | 1.6 | |

| Nominal diameter(mm) | 50-1000 | 50-1000 | |

| Test pressure | Shell | 1.5 | 2.4 |

| (MPa) | Seal | 1.1 | 1.76 |

| Applicable temperature | 150 | ||

| Applicable medium | Fresh water, Sewage, Sea water, Air, Vapor, Food, Medicine, Oils, Acids, Alkalis, etc. |

||

| Operating mode | manual, worm gear, pneumatic, electric, etc. | ||

Standards:

International Standard for Design and Testing of Double Plate Check Valves NRV

Design standard: API 594/API 6D standard

Inspection and testing standard: API 598

Flange to flange distance: According to ANSIBAPl 594/API 6D/ANSI B 16.10

Valve pressure rating: 150#

| Body | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Plate | Ductile Iron, Carbon Steel, Stainless Steel |

| Spring | Stainless Steel |

| Hinge Pin | Stainless Steel |

| Plug | carbon steel |

| Body Bearing | PTFE |

| Spring Bearing | PTFE |

| Stop Pin | Stainless Steel |

| Eye Bolt | Carbon Steel |

| Body Seat | NBR, EPDM, Viton, Neoprene |

A customer in Pakistan purchases check valves, gate valves, pipe fittings, etc.

Main products:

check valve, gate valve, pipe fittings, etc.

Project description:

The client in this case is from Pakistan and is a large-scale local valve distributor. They have their own store locally and often import some valves from abroad to store or supply to local customers.

This client has cooperated with WESDOM many times. Almost every once in a while, they will contact the foreign trade salesman of WESDOM. They bought a batch of valves from WESDOM and stocked them in their store.

Through many cooperations with WESDOM, the two sides have established a very close cooperative relationship. Of course, they contacted WESDOM without hesitation, and purchased check valves, gate valves, pipe fittings, etc. from WESDOM.

Client feedback:

We have worked with WESDOM many times and have been very satisfied each time. We are very willing to maintain a long-term cooperative relationship with WESDOM.

Project pictures:

Application