Product

Product

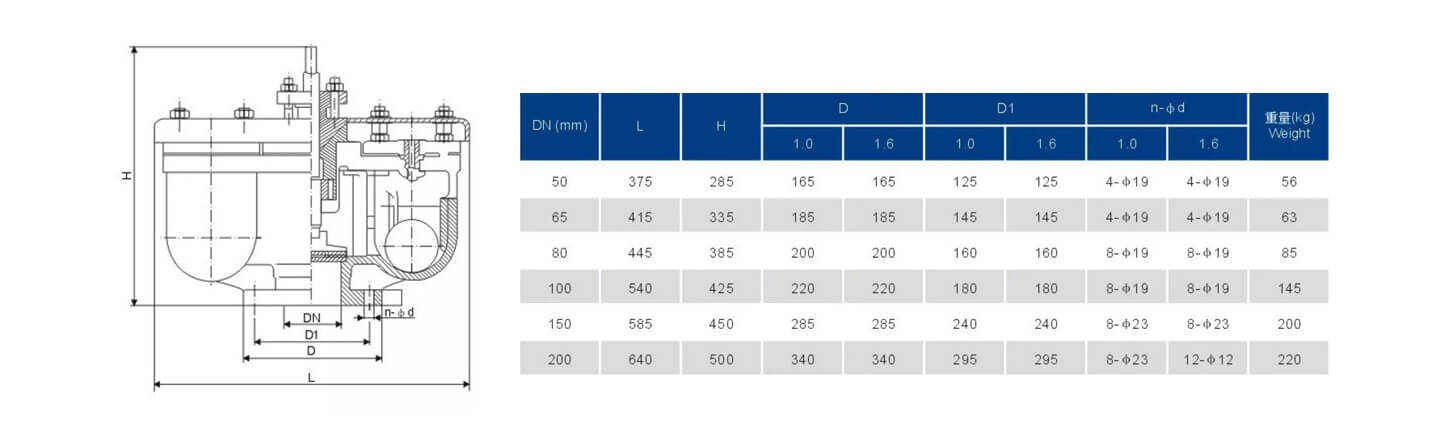

Double ball exhaust valve

Size: 2”~12”

Pressure Rating:PN10-PN25

Material:Ductile Iron

Design Standard:GB12224-2015/EN1074-2000

Inspection Standard:EN12266

Application medium:Water

Application Temperature:0-80℃

Applied projects:Water conservancy construction

Air valves are applied on the water pipelines a8 the equipment to exclude the gas in pipelines, it enhances the efficiency of water transport and protects pipelines from transformation and break. When the pipeline is under negative pressure, this valve will suotion air automatically to prevent the pipeline breaking. Double ball exhaust valve has a big gas displacement fordouble air vents, it owns maintenance valve, close it when repaired then it can be on-line.

Air valves are applied on the water pipelines a8 the equipment to exclude the gas In

pipelines, it enhances the efficiency of water transport and protects pipelines from

transformation and break. When the pipeline is under negative pressure, this valve will suotion

air automatically to prevent the pipeline breaking. This valve has a big gas displacement for

double air vents, it owns maintenance valve, close it when repaired then it can be on-line.

Features:

(1)Advanced design with simple mechanism, strong float to prevent cracking during sudden water hammer and quick closure.

(2)Self-moving mechanism to resist blow shut under higher air velocity even up to sonic velocity of air.

(3)No arms or levers to prevent vibrating, bending, direct closure of the float.

(4)Smooth cage outside of the float, keep float moving in specified guide rail.

(5)Bottom rubber buffer for collision prevention, and drain easy with proper holes around the cage during vacuum.6.Outside screen will be an option for safety and prevent insects and birds in.

(6)Fully fusion epoxy coated inside and outside of valve for long service life.

(7)Good for distribution pipeline system, if for transmission pipeline with high impact water hammer, the anti shock device should be required.

Double air valves have three functions :

(1)Evacuation of air at a high flow rate when pipes are being filled ;

(2)Intake of air at a high flow rate when pipelines are being drained (protection of the network against a pressure drop in the pipelines in the case of a main being broken) ;

(3)Degassing at a low flow rate when in operation.

Application