Product

Product

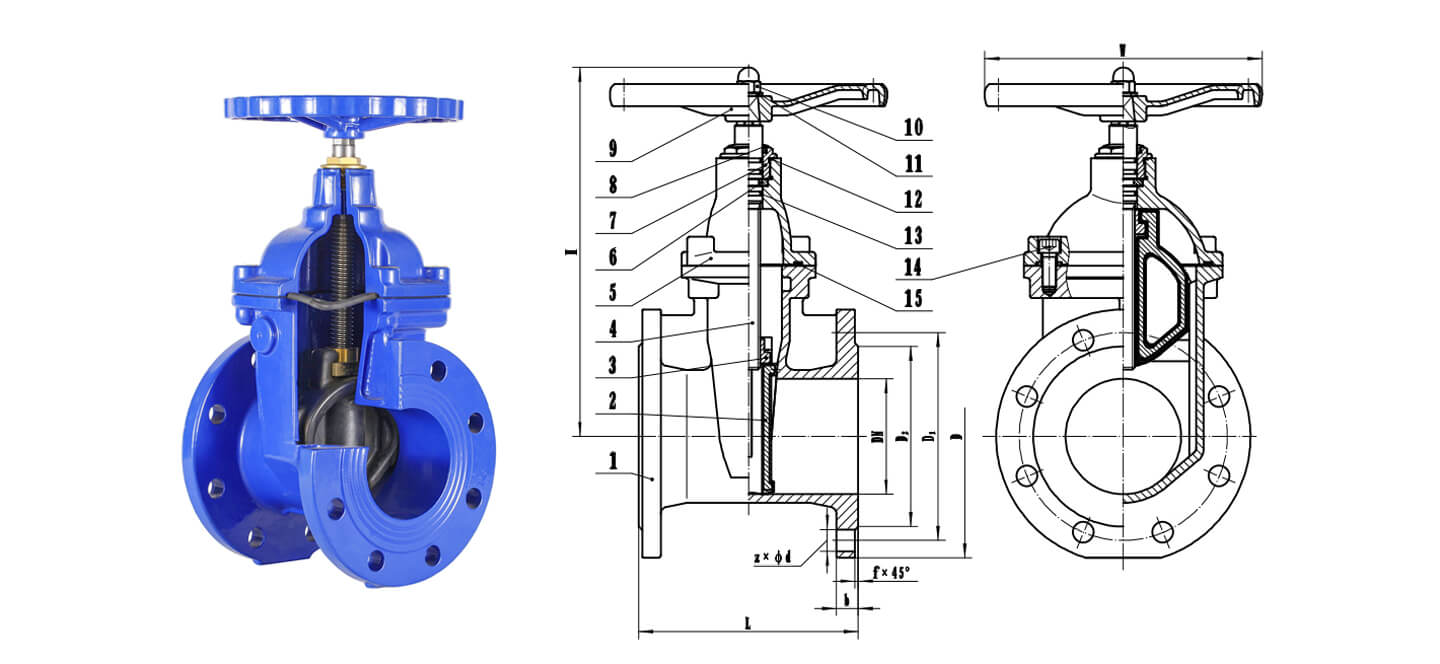

DIN F4 DI Flange resilient EPDM gate valve

Size:DN50-DN300

Pressure Rating:PN16/PN25

Material:Ductile Iron

Design Standard: DIN3352 F4, LIGHT TYPE

Inspection Standard:EN12266

Application medium:Drinking water、sewage、seawater、irrigation,or other neutral liquid

Application Temperature:-40C°-150C°

Applied projects:Drinking water、sewage、seawater、irrigation,or other neutral liquid

The ductile iron core is fully vulcanized with EPDM rubber, no iron parts are exposed to the medium and the excellent rubber vulcanization prevents creeping corrosion underneath the rubber.

Technical parameters

Application

The ductile iron core is fully vulcanized with EPDM rubber, no iron parts are exposed to the medium and the excellent rubber vulcanization prevents creeping corrosion underneath the rubber.

Main Raw Material:

| 1 | Body | Ductile Iron | 9 | Gland bolt | Steel gr.8.8 |

| 2 | Wedge | Ductile Iron+EPDM | 10 | Handwheel | Ductile Iron |

| 3 | Wedge Nut | Brass | 11 | Gland | Ductile Iron |

| 4 | Stem | Stainless steel | 12 | O-ring | EPDM rubber |

| 5 | Bonnet gasket | EPDM rubber | 13 | Nut | Stainless steel |

| 6 | Bonnet | Ductile iron | 14 | Washer | Steel |

| 7 | Thrust collar | Brass | 15 | Bonnet bolt | Steel gr.8.8 |

| 8 | O-ring | EPDM rubber |

Dimension:

| Size | L | D | C | B | n-d | b | f | H | ||

| DN50 | 150 | 165 | 125 | 99 | 4-19 | 15.5 | 2.5 | 280 | ||

| DN65 | 170 | 185 | 145 | 119 | 4-19 | 15.5 | 2.5 | 305 | ||

| DN80 | 180 | 200 | 160 | 133 | 4-19 | 8-19 | 16.5 | 2.5 | 350 | |

| DN100 | 190 | 220 | 180 | 154 | 8-19 | 16.5 | 2.5 | 390 | ||

| DN125 | 200 | 250 | 210 | 184 | 8-19 | 16.5 | 2.5 | 470 | ||

| DN150 | 210 | 285 | 240 | 210 | 8-23 | 16.5 | 2.5 | 525 | ||

| DN200 | 230 | 340 | 295 | 265 | 8-23 | 12-23 | 17.5 | 2.5 | 630 | |

| DN250 | 250 | 405 | 350 | 355 | 319 | 12-23 | 2.5 | 18.5 | 2.5 | 780 |

| DN300 | 270 | 460 | 400 | 410 | 370 | 12-23 | 12-28 | 21 | 3 | 870 |

Features:

①The ductile iron core is fully vulcanized with EPDM rubber, no iron parts are exposed to the medium and the excellent rubber vulcanization prevents creeping corrosion underneath the rubber.

②Guides in the wedge and on the valve body ensure a uniform closure, safe operation ensured as the guides prevent overloading of the stem.

③Stainless steel stem with rolled threads for high strength.

④The valve can replace stem seals under pressure.

⑤Full bore.

⑥Body inside and outside fusion bonded epoxy coating with excellent corrosion resistant performance.

Standard:

| Design standard | DIN3352 F4, LIGHT TYPE |

| Flange drilling standard | EN1092-2 PN10/PN16 |

| Face to face standard | EN558-1 Series 14 |

| Hydraulic test standard | EN12266 |

| Seat:1.1*PN(in bar), Body:1.5*PN(in bar) |

Tanzania Water Project

Main Products:

Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WESDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WESDOM;

Project pictures:

Technical parameters

| Nominal diameter(mm) | 50~300 | 50~300 | |

| Nominal pressure(Mpa) | 1.0 | 1.6 | |

| Testing pressure | Shell(Mpa) | 1.5 | 2.4 |

| Seal(Mpa) | 1.1 | 1.76 | |

| Suitable temperature | -40°C~150°C | ||

| Suitable medium | Drinking water、sewage、seawater、irrigation,or other neutral liquid. | ||

Application

The gate valve is suitable for use in the piping of various corrosive and non-corrosive fluid media in the engineering systems of furnace, gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation and environmental protection, building water supply and drainage.