Product

Product

Compound exhaust valve

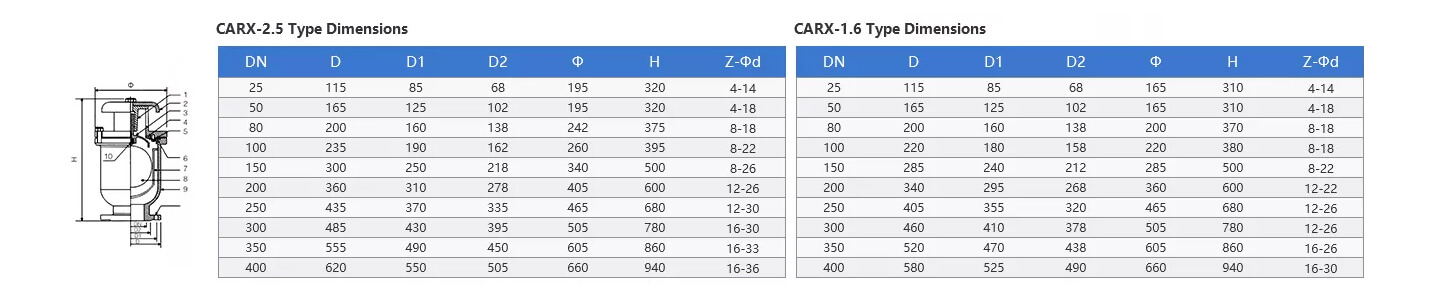

Size: 2”~12”

Pressure Rating: PN10,PN16,PN25

Material: Ductile Iron

Design Standard: GB12224-2015/EN1074-2000

Inspection Standard: EN12266

Application medium: Water

Application Temperature: <=80℃

Applied projects: Water conservancy construction

WESDOM air valves are in good quality. Single ball type and double ball type are all available.

This series of compound exhaust valve is suitable for installation at pumping outlet or in water distribution pipeline. It is used to remove a large amount of air accumulated in the pipeline, or discharge a small amount of air collected at higher place in the pipeline to the atmosphere to improve the use efficiency of the pipeline and the water pump. In case of negative pressure in the pipe, the valve rapidly sucks the outside air to protect the pipeline from damage caused by negative pressure.

Features:

(1)Simple structure and easy installation;

(2)Factory direct supply;

(3)Fine lathe;

(4)Long service life;

(5)Stable performance.

Advantages:

(1)High Grade

Stainless steel surface, long-lasting color, and long-lasting use.

(2)No pollution

Stainless steel material does not release toxic substances, healthy, environmentally friendly, and pollution-free.

(3)Durable

Selected stainless steel material, acid, and alkali resistance.

(4)High hardness

Without cutting corners, the valve body has strong pressure resistance and high hardness.

Wesdom’s exhaust valve type (classification):

Single port exhaust valve, double port exhaust valve, composite exhaust valve.

Principle of operation:

When starting to inject water into a pipeline, the poppet will remain in the open position and exhaust a large amount of air. When the air is exhausted, there will be water in the valve and the float ball will float so as to drive the piston to the closed position, stopping exhausting a large amount of air.

When the water in the pipeline is transmitted normally, if a small amount of air gathers in the valve to certain degree, the water level in the valve will drop and the float ball will drop with it, at this time, the air will be exhausted from the small hole or from the small hole of the automatic exhaust valve. When the water pump stops, in case that the water in the pipeline is empty or the negative pressure is produced in the pipeline, the piston will open rapidly and suck the air so as to ensure the safety of the pipeline.

Products real shot

Application