Product

Product

Cast Iron Rising Stem Resilient Seated Groove Gate Valve

Size:DN65-DN200

Pressure Rating:PN10/PN16

Material:Ductile Iron/Cast Iron

Design Standard: EN1171,EN1074,AS2638

Inspection Standard:EN1171

Application medium:Drinking water , sewage , seawater , irrigation or other neutral liquid

Application Temperature:-40C°-150C°

Applied projects:Water conservancy/ fire/hVAC/building water supply and drainage

Appliction:To be used as the regulating and cut off device in the fluid pipeline of following system: Petroleum/Electricity/Metallurgy/Water/Sewage/Energy/Construction

The ductile iron core is fully vulcanized with EPDM rubber, no iron parts are exposed to the medium and the excellent rubber vulcanization prevents creeping corrosion underneath the rubber.

Features:

(1)The ductile iron core is fully vulcanized with EPDM rubber, no iron parts are exposed to the medium and the excellent rubber vulcanization prevents creeping corrosion underneath the rubber.

(2)Guides in the wedge and on the valve body ensure a uniform closure, safe operation ensured as the guides prevent overloading of the stem.

(3)Stainless steel stem with rolled threads for high strength.

(4)The valve can replace stem seals under pressure.Full bore.

(5)Body inside and outside fusion bonded epoxy coating with excellent corrosion resistant performance.

| Standard | DIN3352F5, BS5163 |

| Design Standard | EN1092-2 ,PN10/PN16 |

| Flange Drilling Standard | EN558-1 Series15 |

| Face To Face Standard | EN1266 |

| Hydraulic Test Standard | Seat 1.1*PN(in bar), Body :1.5*PN(in bar ) |

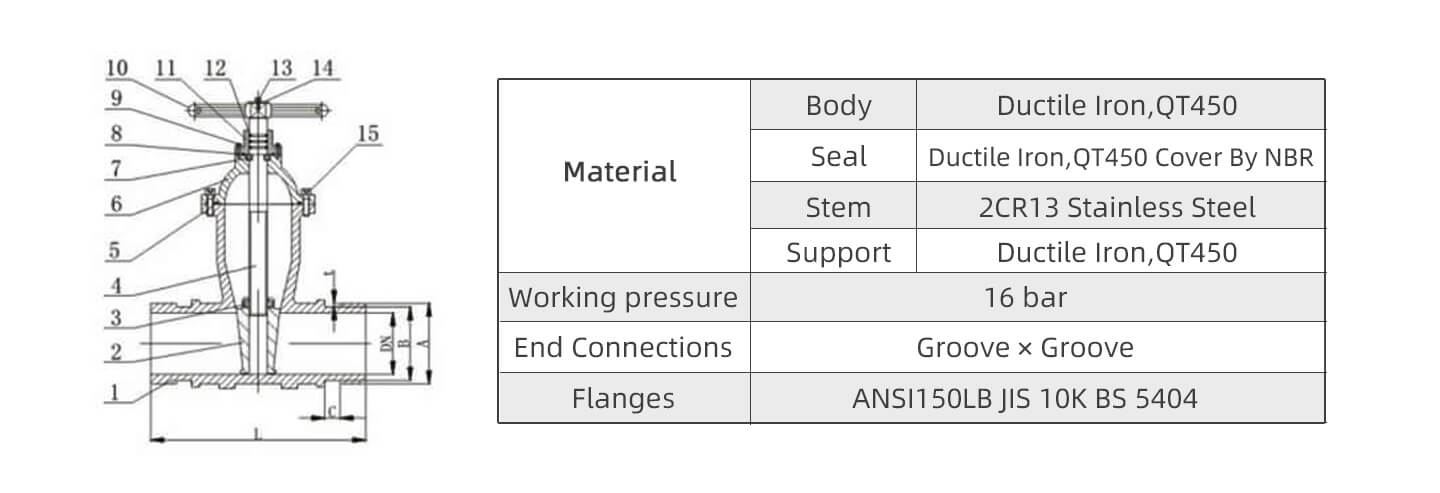

| Main Raw Material | |||||

| 1 | Body | Ductile Iron | 9 | Gland Bolt | Steel gr8.8 |

| 2 | Wedge Disc | Ductile Iron + EPDM Coated | 10 | O-ring | EPDM Rubber |

| 3 | Wedge Nut | Bronze | 11 | Gland | Ductile Iron |

| 4 | Stem | Stainless Steel | 12 | Nut | Steel gr8.8 |

| 5 | Bonnet gasket | EPDM Rubber | 13 | Cap | Ductile Iron |

| 6 | Bonnet | Ductile Iron | 14 | Bonnet Bolt | Steel gr8.8 |

| 7 | Thrust Collar | Brass | 15 | Ruuber Seal | EPDM |

| 8 | O-ring | EPDM rubber | |||

| SIZE | Pipe O.D | OD | Groove Dia | Gasket Seat | Groove Width | Groove Depth | |

| IN | DN | ɸA | ɸB | C | D | t | |

| 2-1/2″ | 65 | 73 | 73 | 69.09 | 15.88 | 7.95 | 1.96 |

| 3″ | 80 | 88.9 | 88.9 | 84.94 | 15.88 | 7.95 | 1.98 |

| 4″ | 100 | 114.3 | 114.3 | 110.08 | 15.88 | 9.53 | 2.11 |

| 6″ | 150 | 168.3 | 168.3 | 163.96 | 15.88 | 9.53 | 2.17 |

| 8″ | 200 | 219.1 | 219.1 | 214.4 | 19.05 | 11.13 | 2.35 |

Technical parameters:

| Technical Parameters | |||

| Nominal Diameter (mm) | 50~300(63-315) | 50~300(63-315) | |

| Nominal Pressure (Mpa) | 1.0 | 1.6 | |

| Testing Pressure | Sell (Mpa) | 1.5 | 2.4 |

| Seal (Mpa) | 1.1 | 1.76 | |

| Suitable Temperature | ̶40C°-150C° | ||

| Suitable Medium | Drinking water , sewage , seawater , irrigation or other neutral liquid | ||

Application

The Groove Gate Valve is widely used as a regulating and shut-off device on the fluid pipelines of tap water, sewage, construction, petroleum, chemical industry, etc.