Product

Product

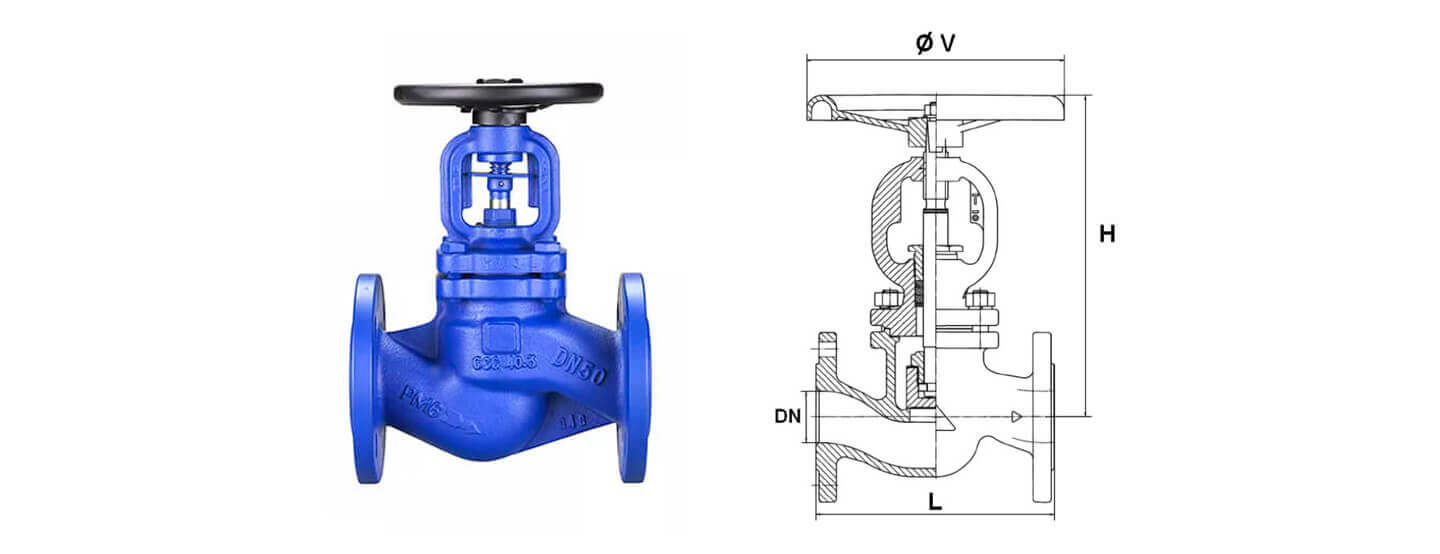

Carbon steel globe valve

Size: 3”~12”

Pressure Rating: PN10,PN16

Material: Gs-c25 、SS304 SS316

Design Standard: DIN EN13709-2003

Inspection Standard: DIN EN12266:2003

Application medium: Gas

Application Temperature: -20℃-425℃

Applied projects: Petrochemical/chemical fiber textile/ plastic paper/electric power steel/printing and dyeing rubber/ natural gas and other gas systems

Products real shot

Application

One of the most frequent and serious problems valves face is gland leakage, results in wasted and increased plant downtime. Apart from the high cost of energy losses, Gland leakages can also cause serious environmental, ecological and health hazards to plant workers and personnel. Leakage of sensitive material can also constitute to a fire hazard, explosion, or damage to equipment by corrosive material. Air entering the pipeline could produce inflammable explosive or poisonous mixtures. Gland packed valves often demand continual maintenance in accessibility creating particular difficulties. The bellows comply to conditions at high temperatures and are capable of withstanding over 10,000 cycles without failure.

The carbon steel globe valve for steam and high temperature has a rising rotating stem and handwheel. The globe valve of this type s recommended for service with hydrocarbons, steam and other high temperaure fluids. The carbon steel globe valve’s stem and seat is made from stainless steel. It follows the flow direction indicated by the arrow.

The globe valve is also made with a rising rotating stem and handwheel and is made primarily for common fluids from the second group, but not to be used for thermic fluids. The stem of this valve must always be kept greased. Other features include bolted bonnet and tightened gland packing during setting.

Carbon steel globe valves are recommended for throttling or regulating flow. This globe valve has a body made of carbon steel A216CWB and a stainless seat.

This carbon steel globe valve is used for throttling flow control. Shut off is accomplished by moving the disc against the flow stream rather than across it as in the case with a gate valve. The flow pattern through the Carbon steel involves changes in direction, resulting in greater resistance to flow, causing high pressure drop.

Production process:

During the production process, castings and cleaning, machining, epoxy coating assembly, pressure testing and storage all processes can ensure product quality.

They are used in industries including oil chemistry, pharmaceuticals, fertilizer and power generation to prevent the backward flux of the media. It is a valve that can realize the open and close according to the force of the working medium.

Pakistan Petroleum Project

Main products:

Bellows Globe Valve and fittings

Project description:

All valves and fittings were through SGS Inspection.

Client feedback:

WESDOM is a very trustworthy team, not only professional, but also caring and enthusiastic in service. If there is a demand in the future, we will choose WESDOM without hesitation.

Project pictures:

Products real shot

Application