Product

Product

API Ball Valve

Size: 1/2”-24”

Pressure Rating: 150LB-600LB

Material: SS304, SS316

Design Standard: API6D,API608

Inspection Standard: API598

Application medium: water, oil, powder

Application Temperature: 0-300℃

Applied projects: Petrochemical, Power plant, Refining, Oil & Gas, Metallurgy etc

API 6D ball valves are designed for reliability and high-performance, and are an excellent choice for shutoff applications in the power, oil & gas and petrochemical industries. API 6D floating ball valve and API 6D trunnion mounted ball valves are available. Ball valve API 6D fully meet the design, manufacture, and testing of API 6D specifications.

WESDOM ball valves are reliable, offering floating type, trunnion mounted type, segment ball type, three-way and four-way type which can be applied in wide range of fields. There are also many kind of sealing material for client’s selection, like PTFE seat, metal seat and ceramics seat, etc.

Features:

(1)API 6D ball valves are designed manufactured to provide maximum service life and dependability.

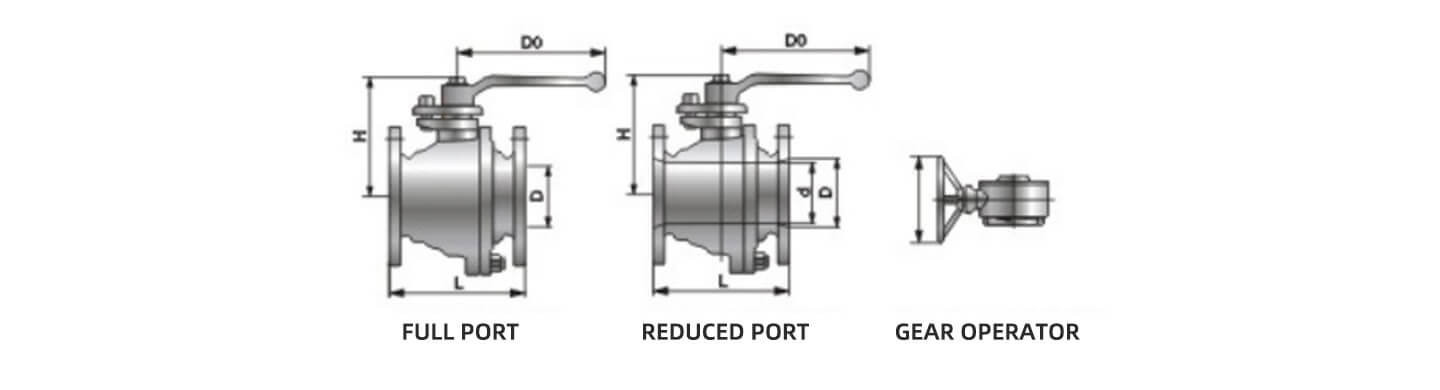

(2)All ball valves are full port or reduced port and meet the design requirements of API 6D.

(3)API 6D ball valves are available in a complete range of body/bonnet materials and trims.

(4)API 6D ball valves are available for the pressure ratings only: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, and Class 2500.

API 6D ball valves are available as below:

(1)API 6D trunnion mounted ball valves & Floating ball valve;

(2)Buttweld and flange ends;

(3)Manual and actuated operation;

(4)Blowout proof stem;

(5)Fire resistant construction;

(6)Anti-static design;

| I Type | NPS(in) | 1/2 | 3/4 | 1 | 11/2 | 2 丨 3 | 4 | 6 | 8 | |||||

| 全通径 Full bore | D(mm) | 13 | 19 | 25 | 38 | 51 | 64 | 76 | 102 | 203 |

| L(mm) | 108 | 117 | 127 | 165 | 178 | 203 | 229 | 394 | 457 | |

| H(mm) | 61 | 66 | 76 | 95 | 142 | 156 | 181 | 270 | 345 | |

| Do(mm) | 130 | 130 | 160 | 230 | 400 | 400 | 700 | 300, | 300* | |

| 缩径 Reduced bore | NPS(in) | 3/4, 1/2 | 1*3/4 | 1«/2*1 | 2*H/2 | 3*2 | 4*3 | 6*4 | 8*6 | 10*8 |

| L(mm) | 117 | 127 | 165 | 178 | 203 | 229 | 267 | 292 | 330 | |

| D(mm) | 19 | 25 | 38 | 63 | 76 | 102 | 152 | 203 | 254 | |

| H(mm) | 82 | 85 | 100 | 120 | 153 | 162 | 119 | 290 | 340 | |

| Do(mm) | 130 | 130 | 160 | 230 | 400 | 400 | 460 | 300* | 300* | |

| d(mm) | 13 | 19 | 25 | 51 | 63 | 76 | 105 | 152 | 203 | |

Material list:

| Material List | ||

| No. I | Parts | | Material | |

| 1 | Body | ASTM A216Gr.WCB |

| 2 | Seat Seal | PTFE |

| 3 | Ball | 304S.S. |

| 4 | Stem | ASTMA182F6a |

| 5 | Gasket | PTFE |

| 8 | Packing | PTFE |

| 12 | Lever | ASTMA216Gr.WCB |

| 16 | Bonnet | ASTMA216Gr.WCB |

| 17 | Stud | ASTMA193Gr.B7 |

Specifications:

| Design and Manufacture | API 6D |

| Wall Thickness | API 6D |

| Face-to-Face Dimension | API 6D |

| Flange End Dimension | ANSI/ASME B16.5 (1” to 24”) ANSI/ASME B16.47 (26” & up) |

| Butt-Weld End Dimension | ANSI/ASME B16.25 |

| Inspection & Testing | API 6D/API 598 |

| Fire Safe Design | API 607/BS 6755 |

| Material | Nace MR 0175 |

Application