Case

Case

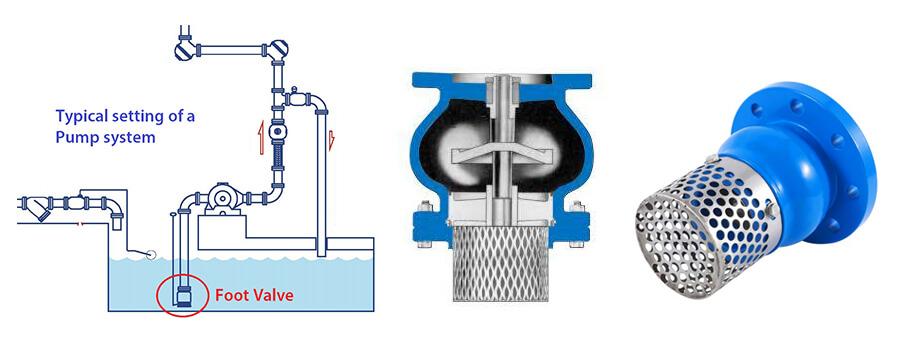

The foot valve, as an important component in the fluid control system, is mainly used to prevent the backflow of liquid. It is generally installed at the suction port of the pump to ensure that the liquid will not flow back when the pump stops working, thereby protecting the safety and effectiveness of the system.

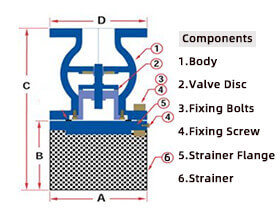

The basic structure of the bottom valve includes the valve body, valve disc, valve seat and sealing ring. The valve disc usually uses a spring mechanism to open automatically when fluid flows.

When the liquid flows, the valve disc of the bottom valve opens under the action of pressure, allowing the liquid to pass smoothly; when the pump stops or reverse flow occurs, the valve disc quickly closes, effectively preventing the liquid from flowing back. The sealing performance between the valve seat and the valve disc is directly related to the working efficiency and service life of the bottom valve. Therefore, choosing high-quality materials (such as stainless steel) to make the bottom valve can greatly improve its durability.

Foot valves are designed to increase the efficiency and safety of fluid delivery systems. Key benefits include:

1. Prevent backflow: The core function of the bottom valve is to prevent liquid from flowing back after the pump stops working, thereby protecting the pump and pipeline system and ensuring a stable supply of fluid.

2. Improve system efficiency: By reducing liquid backflow, the foot valve can improve the suction efficiency of the pump, reduce bubbles and noise, and ensure the normal operation of the pump.

3. Wide applicability: The foot valve is not only suitable for water treatment systems, but also widely used in many fields such as petrochemical industry and food processing, becoming an indispensable part of industrial applications.

4. Stainless steel material: Stainless steel bottom valve has excellent corrosion resistance and strength, and can be used for a long time in various harsh environments, ensuring the stability and safety of the equipment.

5. Simple maintenance: The structure of the bottom valve is relatively simple, and routine maintenance and inspection are convenient, which helps to reduce the long-term operating cost of the equipment.

1. Water treatment system: In water pumping stations and sewage treatment plants, the bottom valve can effectively prevent liquid backflow and ensure the normal operation of the pump.

2. Petrochemical industry: In petroleum refining and chemical production, the bottom valve can prevent the backflow of raw materials and finished products, improve production efficiency and ensure safety.

3. Firefighting system: The bottom valve is equally important in the fire pump system, which can maintain the pressure of the water source and ensure the effectiveness of firefighting equipment in emergencies.

4. Agricultural irrigation: In agricultural irrigation systems, the bottom valve can ensure the stability of irrigation water flow and reduce the waste of water resources.

Maintain pump suction pressure: By preventing liquid from flowing back, the foot valve maintains pump suction pressure and ensures normal pump operation.

Improve pump efficiency: reduce backflow, improve pump efficiency, and save energy.

Protect equipment: Prevent damage to pumps and piping systems and extend equipment life.

1. Select the appropriate foot valve: According to the flow and pressure requirements of the system, select the appropriate model of foot valve to ensure that it can meet the working conditions.

2. Check the sealing ring: Before installation, check the sealing ring of the bottom valve to ensure that it is intact to ensure good sealing performance.

3. Installation direction: The installation direction of the bottom valve should be consistent with the direction of fluid flow. Usually the flow direction will be marked on the valve body, so pay attention during installation.

4. Fix the valve body: Fix the bottom valve in the appropriate position of the pipeline, ensuring that it is perpendicular to the pipeline to avoid failure due to the influence of gravity.

5. Connect the pipeline: According to the pipeline requirements of the system, connect the bottom valve and the pipeline to ensure the sealing of the connection and prevent leakage.

6. Test function: After the installation is completed, perform a system pressure test to check the working status of the bottom valve to ensure its normal operation.

The main reasons for foot valve leakage are as follows:

1. Wear of the sealing ring: After being used for a period of time, the sealing ring may lose its sealing properties due to wear and tear, resulting in water leakage.

2. The valve disc is stuck: The valve disc is stuck due to dirt, sediment or rust, and cannot be completely closed, causing liquid leakage.

3. Improper installation: If the bottom valve is installed improperly, such as incorrect positioning or poor sealing, it will also cause water leakage.

4. Excessive pressure: The pressure in the system exceeds the bearing capacity of the bottom valve, which may cause the valve body to rupture or seal to fail.

5. Material fatigue: Under extreme working conditions such as high temperature and high pressure, the material of the bottom valve may fatigue, causing structural damage and water leakage.

1. Replace the sealing ring: Check the sealing ring regularly. If serious wear is found, replace it in time to restore good sealing performance.

2. Clean the valve disc: Clean the bottom valve regularly to remove dirt and sediment to ensure that the valve disc can move freely and prevent jamming.

3. Check the installation: If water leakage is found, check the installation of the bottom valve to ensure that it is in the correct position and the connection is well sealed.

4. Pressure control: Monitor the system pressure regularly to ensure it is within a safe range to avoid water leakage caused by excessive pressure.

5. Replace the bottom valve: If the bottom valve is seriously damaged or the material is fatigued, it is recommended to replace it with a new one to ensure the normal operation of the system.

1. Regular maintenance: Regularly maintain and inspect the bottom valve, and deal with problems in a timely manner to ensure its normal operation.

2. Keep clean: Keep the bottom valve and the surrounding environment clean to avoid impurities entering and affecting the normal operation of the valve disc.

3. Correct installation: Make sure the installation direction and position of the bottom valve are correct to avoid water leakage problems caused by improper installation.

4. Use high-quality materials: Choose high-quality stainless steel foot valves to ensure their corrosion resistance and strength and adapt to various working environments.

5. Monitor system pressure: Monitor system pressure regularly to ensure it is within a safe range and prevent water leakage caused by excessive pressure.

1. Regular inspection: Regularly check the sealing and operating status of the bottom valve, and deal with any problems in a timely manner.

2. Clean the valve body: Keep the bottom valve and its surrounding environment clean to avoid the accumulation of dirt and sediment, which will affect the normal operation of the valve.

3. Lubricate the valve disc: Lubricate the valve disc regularly to ensure smooth movement and avoid wear caused by excessive friction.

4. Replace the sealing ring: According to the usage conditions, replace the sealing ring regularly to ensure that it always maintains good sealing performance.

5. Record maintenance log: Establish a maintenance record of the bottom valve and record each inspection and maintenance for subsequent reference and management.

The foot valve plays an indispensable role in the fluid control system, and its performance directly affects the efficiency and safety of the system. Through correct installation, regular maintenance and reasonable use, the service life of the foot valve can be effectively extended and the stable operation of the system can be ensured. In industrial production and life, the bottom valve is essential. It can not only prevent liquid backflow and improve the efficiency of the system, but also ensure the safety and reliability of the equipment.