Case

Case

Gate valves have a flat closing element that slides in the media flow to open or close the valve. In bronze valve bodies, which are often used in commercial and residential applications, a bronze disc moves up and down to open and close the valve. The valve is designed so that the brass stem remains at the same height relative to the movement of the disc. A PTFE packing is used in the threaded cap to prevent leakage around the stem. The manual valve is actuated by turning a cast iron handwheel.

Packing and Gasket Around the Stem Anti-port gate valves have two ports, an inlet and an outlet. The above gate valves have threaded ports, although welded and flanged connections are available.

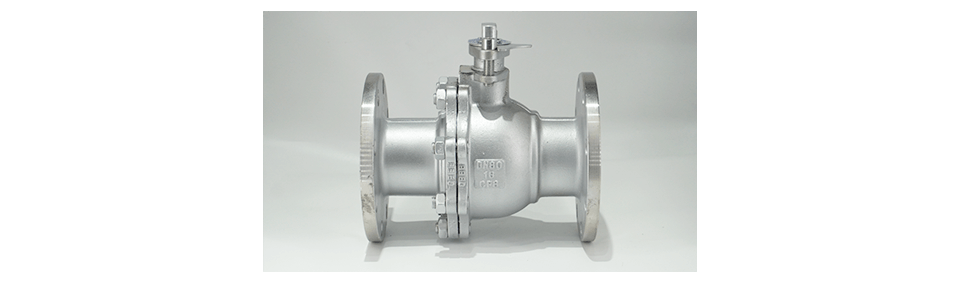

Ball valves have two or more ports. Connect to the port provided by the same selection gate valve. Ball valves made with three ports are used as mixing or diverting valves.

Valve is a mechanical device that controls the flow, direction, pressure, temperature, etc. of flowing fluid media. It is a basic component in the pipeline system.

Let’s take a look at ball valves and gate valves, as well as their respective advantages and disadvantages.

The ball valve evolved from the plug valve. Its opening and closing part is a sphere. The ball is rotated 90° around the axis of the valve stem to achieve opening and closing purposes. Ball valves are mainly used on pipelines to cut off, distribute and change the flow direction of media. Ball valves designed with V-shaped openings also have good flow regulation functions.

① The thrust bearing reduces the friction torque of the valve stem, allowing the valve stem to operate smoothly and flexibly for a long time.

② Anti-static function, a spring is set between the ball, valve stem and valve body, which can discharge the static electricity generated during the switching process.

③ The fluid resistance is small. Pneumatic ball valves have the smallest fluid resistance among all valve categories. Even if they are reduced-diameter pneumatic ball valves, their fluid resistance is quite small.

④ The valve stem seal is reliable. Since the valve stem only rotates and does not move up and down, the packing seal of the valve stem is not easily damaged, and the sealing capacity increases as the medium pressure increases.

⑤ Because the main valve seat sealing ring material of the ball valve is polytetrafluoroethylene, it is inert to almost all chemical substances, and has a small friction coefficient, stable performance, not easy to age, wide temperature range and excellent sealing performance comprehensive characteristics.

The valve seat sealing ring material PTFE has a low temperature resistance level and can only be used when the temperature is less than 180°C. Above this temperature, the sealing material will age. When considering long-term use, it is generally only used at 120°C.

Gate valve refers to a valve whose closing member (gate plate) moves along the vertical direction of the channel axis. It is mainly used to cut off the medium on the pipeline, that is, it is used fully open or fully closed. Generally, gate valves cannot be used to regulate flow. It can be applied to low temperature pressure or high temperature and high pressure, and can be used according to different materials of the valve.

① The flow resistance is small, the medium channel inside the valve body is straight, the medium flows in a straight line, and the flow resistance is small.

② It requires less effort when opening and closing, compared with a stop valve, because whether it is opening or closing, the movement direction of the gate is perpendicular to the direction of the medium flow.

③ The gate has a large height, a long opening and closing time, a large opening and closing stroke of the gate, and the lifting and lowering is performed by a screw.

④ Water hammer is not easy to occur because the shutdown time is long.

⑤ The medium can flow in any direction on both sides and is easy to install. Both sides of the gate valve channel are symmetrical.

Erosion and scratches can easily occur between the sealing surfaces, making maintenance difficult. The overall size is large, it requires a certain amount of space to open, and it takes a long time to open and close.

The flow through a partially open gate valve is proportional to the movement of the closing element. This limits the availability of gate valves for actively controlling media flow, and therefore, gate valves are mainly used as stop valves to isolate equipment or pipeline sections.

Ball valves are designed so that flow is proportional to the rotation of the closing element. This is the so-called "equal percentage modified" flow characteristic. This makes ball valves suitable for actively controlling media flow.

Gate valves are ideal for isolating general purpose flows, as well as high pressure and high temperature applications where operation is rare. For this reason, manual operation is typical, generally via a multi-turn handwheel assembly, although mechanical, pneumatic and electric actuators are available.

Ball valves are manually actuated, as well as by electric and pneumatic actuators as part of a flow control system. One advantage of manually actuated ball valves over gate valves is that the position of the handle makes the position of the ball easy to "see."