Case

Case

What is single-acting and double-acting pneumatic actuator?

When you choose a valve, it is very important to know what kind of actuator your project requires. For the automated valves, the actuator is the component that let the valve to open or close.

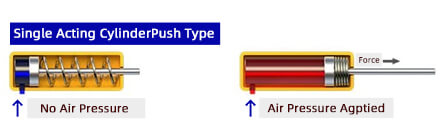

The working principle for single-acting pneumatic actuator is to use air to open the valve, and a spring to close the valve. It is also suitable to use air to close the valve, and a spring to open the valve.

Normal close type: we also call it NC type, it means when give air to valve, the valve will open, when stop the air, the valve will be in normal close type.

Normal open type, we also call it NO type, it means when give air to valve, the valve will close, when stop the air, the valve will be in normal open type.

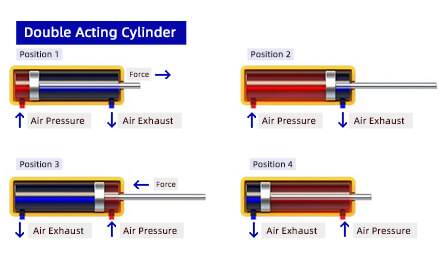

The working principle for double-acting pneumatic actuator is give air to open the valve, and when you want to close the valve, you must give air again.

What is single-acting and double-acting pneumatic actuator?

As introduction above, the single-acting actuators back to normal close/open by the spring, so the most important to use the single-acting pneumatic is for their reliable fail-safe design.

This means that if power or air pressure is lost, the valve will quickly move to the normal position.

This is useful in applications where serious consequences may occur if the valve remains open (or closed) when power and/or air pressure is lost.

For this reason, single-acting actuators are the best choice when the simplicity and reliability of a safety system are of the utmost concern.

But the price for single-acting pneumatic actuator is higher than double-acting pneumatic actuator.

This is the most popular style of pneumatic valve actuator. Double-acting actuators are selected for their lower cost and superior longevity.

Double-acting actuators are ideal for high cycle applications and/or applications where the valve failing to the closed (or open) position when power is lost does not present a critical issue.

Double-acting actuators are the most popular choice for their lower cost and superior longevity. Double-acting actuators are also more compact than single-acting actuators.