Case

Case

The outer diameter of hot-rolled seamless pipes is generally greater than 32mm, and the wall thickness is 2.5-200mm; the outer diameter of cold-rolled seamless steel pipes can be up to 6mm, the wall thickness can be up to 0.25mm, and the outer diameter of thin-walled pipes can be up to 5mm wall thickness Less than 0.25mm, cold rolling has higher dimensional accuracy than hot rolling.

Generally used seamless steel pipes are 10#, 20#, 30#, 35#, 45#, etc.; high-quality carbon structural steel 16Mn, 5MnV, etc.; low alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB, etc. .

Seamless pipes made of low carbon steel such as 10# and 20# are mainly used for fluid transportation pipelines. Seamless tubes made of medium carbon steel such as 45# and 40Cr are used to manufacture mechanical parts, such as stressed parts of automobiles and tractors.

There are many production methods for seamless pipes. Seamless steel pipes can be produced by hot rolling (approximately 80 to 90%) or cold rolling or cold drawing (approximately 10 to 20%) methods according to delivery requirements. The blanks used for hot-rolled pipes include round, square or polygonal ingots, rolled billets or continuous cast billets. The quality of the billets has a direct impact on the quality of the pipe.

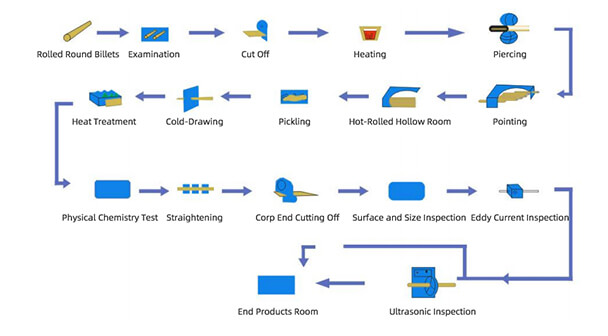

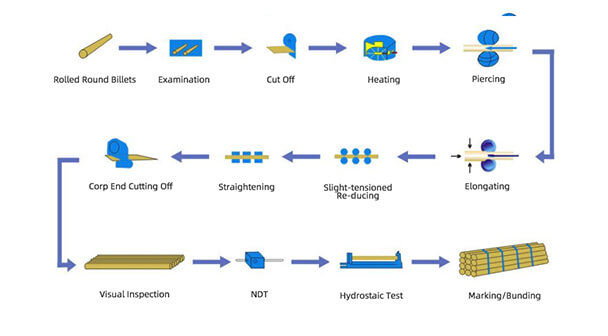

The production process of general seamless steel pipes can be divided into two types: cold drawing and hot rolling. Hot rolling, as the name suggests, has a high temperature of the rolled piece, so the deformation resistance is small and large deformation can be achieved. Take the rolling of steel plates as an example. Generally, the thickness of continuous casting billet is about 230mm, and after rough rolling and finish rolling, the final thickness is 1~20mm. At the same time, due to the small width-to-thickness ratio of the steel plate, the dimensional accuracy requirements are relatively low, and plate shape problems are not prone to occur. The main focus is to control the crown.

Seamless steel pipes play an important role in the national economy and are widely used in various sectors such as petroleum, chemical industry, boilers, power stations, ships, machinery manufacturing, automobiles, aviation, aerospace, energy, geology, construction and military industry.

General-purpose seamless pipes are rolled from ordinary carbon structural steel, low alloy structural steel or alloy structural steel, with the largest output, and are mainly used as pipes or structural parts for conveying fluids.

Seamless steel pipe for fluids: Mainly used for transporting oil and natural gas fluid pipelines, the specifications are generally Φ159-426mm.

Galvanized seamless steel pipe for low-pressure fluid transportation: Mainly used to transport low-pressure fluids such as water, gas, and air. The specifications are generally Φ10-159mm.

Fertilizer equipment is used for seamless steel pipes: Mainly used to transport chemical raw materials such as ammonia and urea. The specifications are generally Φ219-426mm.

Seamless steel pipe for fluids: Mainly used for transporting oil and natural gas fluid pipelines, the specifications are generally Φ159-426mm.

Galvanized seamless steel pipe for low-pressure fluid transportation: Mainly used to transport low-pressure fluids such as water, gas, and air. The specifications are generally Φ10-159mm.

Fertilizer equipment is used for seamless steel pipes: Mainly used to transport chemical raw materials such as ammonia and urea. The specifications are generally Φ219-426mm.

Seamless steel pipe for deep well pump: Mainly used for transporting groundwater, specifications are Φ76-168mm.

a. Supplied according to chemical composition and mechanical properties;

b. Supplied according to mechanical properties;

c. Supply according to hydraulic pressure test. If the steel pipes supplied according to categories a and b are used to withstand liquid pressure, they must also undergo a hydraulic pressure test.

Special-purpose seamless pipes include seamless pipes for boilers, seamless pipes for geology, and seamless pipes for petroleum.

Steel seamless pipes come in handy in several sectors of the fertilizer industry. The regions of application of the lines in the fertilizer industry mainly include piping system equipment, high-pressure tubes in Melamine plants, and heat exchanging systems in Urea synthesis ethylene plants. Other than the above mentioned areas, seamless steel pipes are also used in a variety of sectors in the industry.

Steel seamless pipes and tubes are used primarily as heat exchangers in giant power plants and the energy department. Environmental uses and waste incineration plants also utilize the same application style known as reheater superheaters.

Steel seamless plants prove highly useful in chemical and petrochemical industries. The area of application in the chemical and petrochemical sectors mainly includes the following: High-pressure pipes in Melamine plants, elaborate piping systems and heat exchanging systems of urea synthesis ethylene plants.

Various processes of ship-building require the use of steel seamless pipes and tubes. While it is difficult to export a readymade ship, it is comparatively easier to export parts that will be used to build the ship. As per the request of international dealers, a variety of steel seamless pipes are exported to distant lands. These tubes are then used in the manufacturing process of shipbuilding.

Steel seamless pipes are a common requirement for oil casing and tubing for offshore and onshore Oil & Gas transfer. The oil extracted offshore needs large tubes to be transferred from one reservoir to another. Not all materials can support unprocessed raw oil. Steel seamless pipes are a perfect application for such purposes.

Steel seamless pipes are highly used in engineering and construction industries in the following sectors: automobile designing technology, food manufacturing industry, measurement and control technology, hydraulic press, cylinders and pumps, etc.

Seamless pipes and tubes are used in petroleum extraction, connecting and transporting various liquids such as water, gas and other fluids. Seamless steel pipes are also used in commercial and residential walls, laboratories, and industrial structures.

To sustain high temperature and pressure in factories, only resilient seamless steel pipes of various ranges are used. Seamless tubes and pipes are valuable for transferring liquids in large containers, heating pipelines and boilers, and high-temperature reheaters.

Seamless steel pipes are steel pipes that are impact-resistant, friction-resistant, corrosion-resistant and have a long service life.

Ordinary carbon steel can withstand temperatures up to 350°C. If special alloy elements such as chromium, nickel, tungsten, and titanium are added during production, the seamless steel pipe can withstand temperatures around 600°C, which enhances its unique use.

The temperature resistance of plastic pipes (PVC, UPVC, PPR, aluminum-plastic pipes) commonly used in life and production is only about 100°C.

Seamless steel pipes have excellent mechanical properties. Ordinary seamless carbon steel pipes can withstand pressures from 1.6MPa to 6.4MPa. If special alloy elements are added during production, the pressure resistance can reach ultra-high pressure, thus meeting the needs of special production processes. This is one of its most important advantages over cast iron pipes, copper pipes, aluminum pipes, and various non-metallic pipes.

Seamless steel pipes have excellent weldability and are easy to lengthen butt, plug in, etc. It is difficult to compare with cast iron pipes, reinforced concrete pipes, etc.

The inner surface of seamless steel pipe is smooth and the transportation resistance is very small.

Seamless steel pipe is resistant to high temperature, high pressure, mechanical stamping, has little resistance, and is easy to connect and lengthen. Therefore, it is the best material for long-distance transportation of fluids.

Seamless steel pipes can be cut when in use. The purpose of cutting is to meet the usage requirements. Therefore, the length and other dimensions must be measured before cutting to meet the usage requirements. When cutting, you must choose appropriate tools. Generally, metal saws, toothless saws and other tools can be used for cutting. At the same time, both ends of the fracture must be protected, that is, use fireproof and heat-resistant baffles to prevent splashing sparks. , hot iron beans, etc.

Seamless steel pipes need to be polished after cutting. This can be done with an angle grinder. The purpose of polishing is to avoid pipe damage caused by melting or burning of the plastic layer during the welding operation.

After the seamless steel pipe is polished, it needs to be protected by plastic coating. That is, heating the pipe mouth with oxygen and C2H2 will cause partial melting. Then apply plastic powder. It must be applied in place and evenly. If it is a flange If it is a plate, it needs to be applied to the position above the water stop line. When heating, the temperature must be controlled to avoid bubbles caused by too high a temperature and the plastic layer falling off due to the inability to melt the plastic powder at too low a temperature.