Case

Case

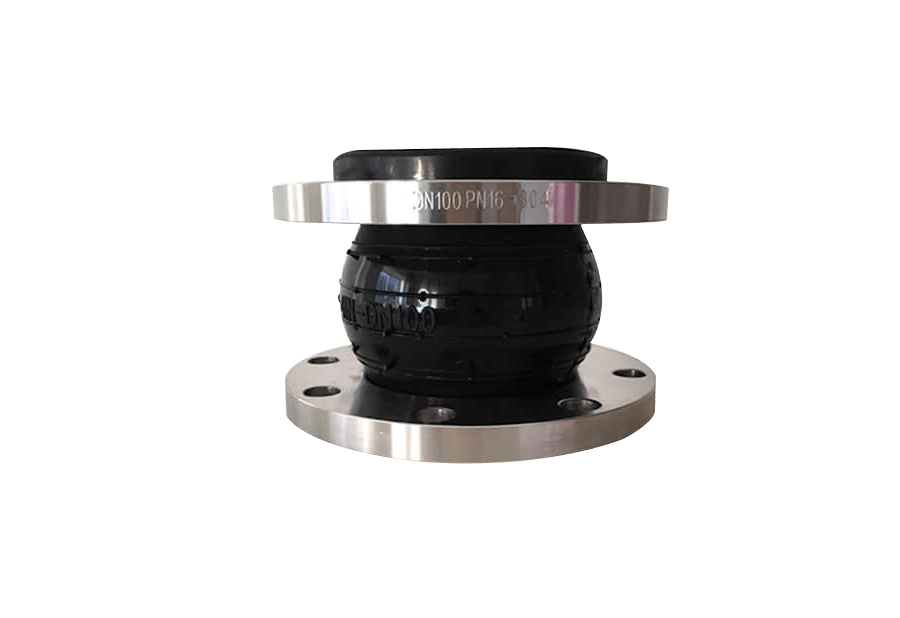

Rubber joint is also called rubber pipe soft joint, flexible rubber joint, rubber soft joint, flexible winding rubber joint, high pressure rubber joint, rubber shock absorber, compensator, etc. According to the connection mode, there are three types of flange, fixed flange and thread; according to the structure, it can be divided into 5 kinds: single sphere, double sphere, diameter, curved sphere and wind coil. It consists of tubular rubber parts composed of inner and outer rubber, curtain layer and steel wire ring, and then combined with metal flange or parallel joint loose sleeve. This product can reduce vibration and noise, and can compensate for thermal expansion and contraction caused by temperature change, and is widely used in various pipe systems.

1. According to the use of performance, it is divided into general, special and heat resistant.

General class: suitable for water with delivery temperature of 15℃ ~80℃, acid solution or alkali solution with less than 10%.

Specific type: suitable for special performance requirements, such as oil resistance, plug resistance, ozone resistance, wear resistance or chemical corrosion resistance.

Heat resistance: suitable for water conveying temperature higher than 80℃.

2.According to the structural form, it is divided into single sphere, double sphere, three spheres, elbow sphere, air pressure coil body, etc. Each form can be divided into concentric equal diameter, concentric different diameter, eccentric different diameter three categories.

3. According to the appearance of:

Concentric with the same diameter, concentric different diameter, eccentric different diameter.

4.According to the connection form of product and pipeline, it can be divided into flange connection, threaded connection and clamp connection, threaded pipe flange connection, etc.

5.According to the working pressure points: 0.25MPa, 0.6MPa, 1.0MPa, 1.6MPa, 2.5MPa, 6.4MPa Six levels.

1.Flexible vibration absorption and shock absorption: rubber joints can absorb and reduce vibration and shock in the pipeline system, reduce damage to pipelines and equipment, and protect the system's normal operation.

2.Good sealing performance: rubber joints can effectively seal the pipeline system to prevent media leakage and ensure the safe and reliable operation of the system.

3.Excellent corrosion resistance: certain rubber materials have good corrosion resistance, which can adapt to the corrosive media's working environment and extend the joint's service life.

4.Good adaptability and flexibility: rubber joints can adapt to different diameters and different materials of pipe connections, providing flexible installation and connection solutions.

5.High-pressure resistance: rubber joints can withstand high pressure, maintaining the stability and safety of the pipeline system.

6.Good wear resistance: rubber joints have a certain degree of wear resistance and can maintain stable performance and life in long-term operation.

1.Industrial pipeline system: rubber joints are widely used in pipeline systems of chemical, petroleum, electric power, metallurgy, and other industrial fields to connect various equipment and facilities.

2.Sewage treatment system: rubber joints can be used in sewage treatment plants, sewage pipes, and other occasions to withstand sewage's impact and pressure changes.

3.HVAC system: rubber joints are often used in HVAC systems to connect air ducts, fans, units, and other equipment to reduce vibration and noise transmission.

4.Water supply and drainage systems: rubber joints can be used in urban water supply and drainage piping systems, adapting to the connection needs of different materials and pipe diameters.

5.Petroleum and chemical transport systems: rubber joints are suitable for petroleum and chemical transport pipelines and are able to withstand high pressure and corrosive substances in the medium.

The rubber joint is a pipeline connection component with excellent characteristics and wide application. Its elasticity, vibration absorption, damping, good sealing performance, corrosion resistance, adaptability, and pressure resistance make it an indispensable component of industrial piping systems. In different working conditions and applications, rubber joints can play an important role in providing a reliable connection and operating environment.

We have always abided by our commitment to partnerships, meeting or exceeding the requirements of each customer.

We look forward to working with you!

To learn more about our products, please contact:

WhatsApp: +86 13849184495