Case

Case

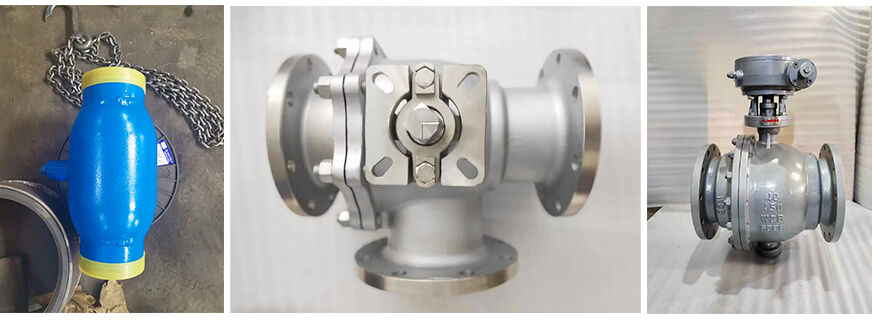

There are many kinds of ball valve structure, but basically similar, are opening and closing parts for the round sphere, mainly by the valve seat, ball, sealing ring, valve stem and other driving devices, etc., through the valve stem rotated by 90 degrees so as to achieve the valve open and close, in the pipeline for the shut-off, distribution, adjusting the size of the flow rate and change the direction of flow of the medium. Valve seat according to the different conditions of the use of different valve seat sealing form.

O-type ball valve valve body is installed inside the middle of the through-hole ball, the ball on the body of a diameter and the diameter of the pipeline is equal to the through-hole, the ball can be rotated in the sealing seat, in the direction of the pipeline on each side of a ring-shaped elastomer to achieve sealing.

V-type ball valve spool with V-shaped structure, the spool is 1/4 ball shell, open V-shaped notch, large circulation capacity, adjustable range, with shear force, can close tightly and other characteristics, especially for fluid substances with fibrous conditions.

O-type ball valves are installed inside the valve body with a through-hole in the middle of the ball, the ball is open with a diameter equal to the diameter of the pipeline through-hole, the ball can be rotated in the sealing seat, in the direction of the pipeline on both sides of each side of the ring-shaped elastomer to achieve sealing. By rotating the ball body 90 °, you can change the direction of the through hole, so as to achieve the ball valve switch. o-type ball valve with floating or fixed design, relative movement parts are used in the friction coefficient of very small self-lubricating materials, so the operating torque is small, in addition to the sealing grease sealing for a long period of time, so that the operation of a more flexible, its product advantages are as follows:

Ball valves generally have through, reduced two structures, regardless of which structure, the ball valve flow resistance coefficient is relatively small. Conventional ball valves are straight-through, also known as full-flow type ball valves, the channel diameter is equal to the inner diameter of the pipeline, the resistance loss is only the friction resistance of the same length of the pipeline. Among all valves, this type of ball valve has the smallest fluid resistance. There are two ways to reduce the resistance of the piping system: one is to reduce the fluid flow rate, the way is to increase the diameter of the pipe and valve diameter, which will greatly increase the cost of the piping system. The second is to reduce the local resistance of the valve, the ball valve is the best choice.

Ball valves only need to turn 90 degrees to complete the full open or close, so it can quickly open and close.

The vast majority of ball valve seats are made of polytetrafluoroethylene (PTFE) and other elastic materials, usually called soft seal ball valve. Soft seal ball valve has good sealing performance, and the valve sealing surface roughness and processing accuracy requirements will not be very high.

Polytetrafluoroethylene (PTFE or F4) has good self-lubrication, and the friction coefficient of the ball is small. As a result of improved processing technology to reduce the roughness of the ball, thus greatly improving the service life of the ball valve.

The ball and the valve seat a pair of sealing vice will not occur abrasion, sharp wear, and other failures;

After the valve stem is changed to internal mounting type, it eliminates the hidden danger of accident that the valve stem may fly out due to loosening of packing gland under the action of fluid pressure;

The ball valve with anti-static and fire-resistant structure can be used for pipelines conveying oil, natural gas and gas.

O-type ball valve spool (ball) is spherical, from the structural point of view, sealing the ball seat embedded in the valve body side seat. Relative movement parts are used in the friction coefficient is very small self-lubricating materials, so the operating torque is small, in addition to the sealing grease long-term sealing, making the operation more flexible. Generally used for two-position adjustment, the flow characteristics of fast-opening.

The o-type ball valve is fully open, the two sides of smooth for the unimpeded valve, the formation of a straight pipe channel, two-way sealing, with "self-cleaning" performance of the best features, suitable for the two cut-off occasions, especially unclean, containing fibre media. Ball core in the process of opening and closing the valve is always friction with the valve, at the same time, the seal between the valve core and seat is through the seat pressure to the ball core of the pre-tensioned sealing force to achieve, but due to the soft sealing seat of its excellent mechanical and physical properties, making its sealing is particularly good.

V type ball valve spool with V structure, the spool is 1/4 ball shell, open V notch, large circulation capacity, adjustable range, with shear force, can close tightly, etc., especially suitable for fluid material with fibrous conditions. Generally, V type ball valve is a single seal ball valve. Not ideal for two-way use.

V-shaped edge, cut off impurities. In the ball rotation process, the ball V-shaped cutter and the valve seat tangent, thus cutting off the fluid fibers and solid substances, and general ball valves do not have this function, so it is easy to lead to the closure of the fiber impurities stuck, to the maintenance and repair brought great inconvenience. The V-ball valve spool will not be stuck by the fiber. In addition, due to the use of flange connection form, and thus its easy disassembly, maintenance is also simple and easy without special tools. When the valve is closed, the V-notch and the seat of the valve produce a deed-shaped scissor effect, and both self-cleaning function and can prevent the ball core jammed, the valve body, the valve cover, and the valve seat were used in the metal point-to-point structure, in addition to the use of a smaller friction coefficient of the valve stem spring, so the operating torque is small, very stable.

V-ball valve is a right-angle rotary structure that can achieve the role of flow regulation, and can be based on the V angle of the V-ball body to achieve different degrees of proportionality, V-ball valves are generally used in conjunction with the valve actuator and positioner to achieve proportionality, V-type spool is most suitable for a variety of regulating occasions, with a large coefficient of flow rating, adjustable ratio, sealing effect, zero-sensitive regulating performance, small size, can be vertically and horizontally mounted. Suitable for controlling gas, steam, liquid, and other media. v-ball valve is a right-angle type rotary structure, composed of v-body, pneumatic actuator, positioner, and other accessories; there is an approximate equal hundred ratio of the intrinsic flow characteristics; the use of double-bearing structure, start-up torque is small, with excellent sensitivity and sensing speed, superb shear capacity.