Case

Case

The opening and closing part of the mechanical joint gate valve is the gate. The movement direction of the gate is perpendicular to the direction of the fluid.

When the gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, only relying on the medium pressure to press the sealing surface of the gate to the valve seat on the other side to ensure the sealing of the sealing surface, which is self-sealing.

Most gate valves are forcibly sealed, that is, when the valve is closed, the gate must be forced against the valve seat by external force to ensure the tightness of the sealing surface.

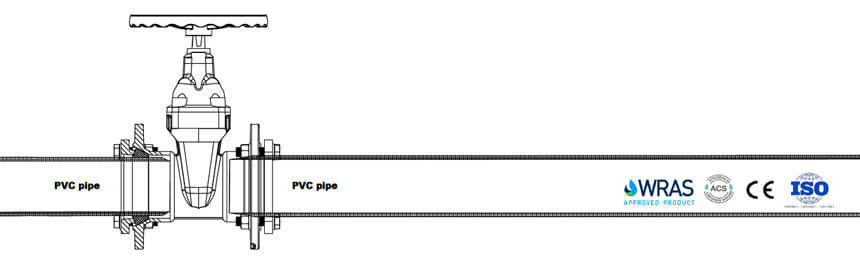

The connection method of the mechanical joint does not require additional flange joints, and can be directly inserted into the pipeline, which is very convenient and reduces the cost.

The body is made of high-grade ductile iron, which is about 20%~30% lighter than the traditional gate valve, and is easy to install and maintain.

The traditional gate valve often accumulates in the groove at the bottom of the valve due to foreign objects such as stones, wood blocks, cement, iron filings, sundries, etc. after the pipe is washed with water, which is easy to cause water leakage due to failure to close tightly.

The bottom of the elastic seat seal gate valve adopts the same flat bottom design as the water pipe machine, which is not easy to cause debris accumulation and makes the fluid flow unobstructed.

The gate is made of high-quality rubber for the overall inner and outer covering. The European rubber vulcanization technology enables the vulcanized gate to ensure accurate geometric dimensions, and the rubber and the ductile cast gate are firmly bonded and not easy to fall off. And good elastic memory.

The valve body adopts precision casting, and the precise geometric dimensions make the valve body internal without any finishing to ensure the sealing performance of the valve.

The gate valve adopts a different connection method from the previous one. Traditional gate valves mostly use flanges, threads, etc.

The mechanical joint is a new product of our company. It is a special valve connection method. It can be directly inserted into the connecting pipe without the need for a flange joint, which is very convenient to use.

1. A water stop notice should be issued before construction.

2. Avoid road surface water before construction.

3. Construction electricity must be guaranteed.

4. It is strictly forbidden to use the handwheel, handle and transmission mechanism for hoisting, and collision is strictly prohibited.

5. If the valve is used frequently, lubricate it at least once a month.