Case

Case

The three-way ball valve is a commonly used valve. Its main function is to control the flow direction of the fluid medium in the pipeline. This valve has the advantages of simple structure, convenient operation, and good sealing performance, and is widely used in various industrial pipeline systems.

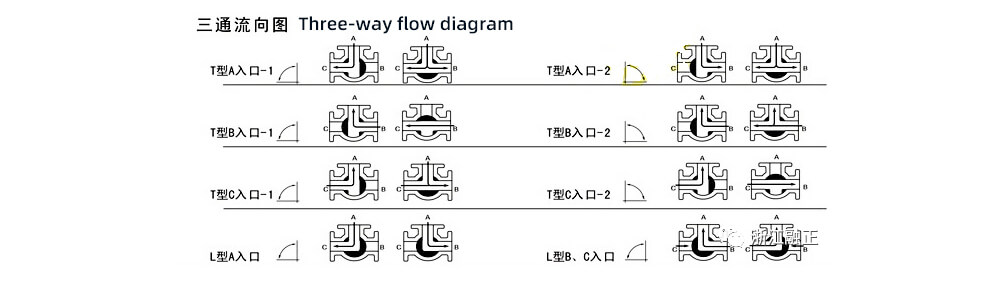

Three-way ball valves are mainly used in pipelines to cut off, distribute and change the flow direction of media. The three-way ball valve is a three-way rotary ball valve. The valve core of the flange three-way ball valve is L-shaped and T-shaped, which can meet the requirements of different production processes. Any pipe can be used as an inlet or outlet as required. The L-shaped valve cuts off two of the three pipelines, while the T-shaped valve realizes the merging and separation of the three connecting pipelines.

Three-way ball valve is mainly composed of valve body, valve ball, valve stem, handle, etc. Its working principle is based on the rotational motion of the ball. By changing the position of the ball in the valve body, the flow direction of the fluid medium is controlled.

Specifically, when the handle rotates clockwise, the ball gradually moves to the right along the valve seat in the valve body. At this time, the fluid medium flows in from the left side, passes through the seal between the ball and the valve seat, and flows out from the right side. On the contrary, when the handle rotates counterclockwise, the ball moves to the left, the fluid medium flows in from the right side, and flows out from the left side after being sealed.

In the design of the three-way ball valve, the shape and size of the flow channel of the valve body directly affect the flow characteristics of the fluid medium. In order to reduce the pressure loss and flow resistance of the fluid medium in the valve body, the flow channel of the valve body is usually designed to be streamlined to reduce the turbulence and vortex of the fluid medium.

In addition, the sealing performance of the three-way ball valve is crucial to ensure the safety and reliability of the pipeline system. In order to achieve good sealing performance, the contact surface between the valve seat and the ball needs to be finely processed and ground to ensure the smoothness and precision of the contact surface. At the same time, a certain elastic sealing material is used between the valve seat and the ball to adapt to the sealing requirements under different working conditions.

(1) Compact structure, rapid opening and closing, smooth flow path and small fluid resistance.

(2) Easy maintenance: After depressurizing the system, inspection and maintenance can be performed without disassembling the entire valve body.

(3) Good sealing performance: The elastic deformation of the four-sided valve seat material PTFE can achieve leak-free sealing.

(4) One valve has multiple uses: any port can be used as an inlet without leakage. The tee can be made into an L-shaped port or a T-shaped port.

(5) It is used to switch the flow direction of the medium in pipeline systems such as water supply, petrochemical, metallurgy, mining, textile, energy, papermaking, food, steel, etc., as well as to divert the medium or mix fluids.

Select the appropriate three-way ball valve type according to the process requirements and operating conditions of the pipeline system. For example, depending on the nature and pressure level of the fluid medium, choose a full-bore or reduced-bore ball valve.

The three-way ball valve should be installed in a manner that facilitates operation and maintenance. Generally, it is recommended to install the valve on a horizontal pipe to facilitate the operation of the handle. At the same time, ensure that the valve is installed securely to prevent vibration or looseness during operation.

When installing a three-way ball valve, the correct valve connection size should be selected based on the size and specification of the pipe. Ensuring the accuracy of connection dimensions is critical to ensuring the sealing performance of the valve.

Before installing a three-way ball valve, it is necessary to understand the pressure and medium type of the pipeline system. For high-pressure pipeline systems, special attention should be paid to the pressure resistance and sealing performance of the valve. For corrosive media, appropriate corrosion-resistant materials should be selected to extend the service life of the valve.

When installing a three-way ball valve, consider sufficient space required for valve operation. If there is insufficient space, the operation and maintenance of the valve may be affected. Therefore, when installing the valve, make sure there is enough operating space around it.

When installing a three-way ball valve, be sure to follow the operating instructions provided by the manufacturer. Installation in accordance with the operating instructions ensures the safety and reliability of the valve, while also helping to extend the service life of the valve.

In actual applications, the appropriate three-way ball valve type must be selected according to specific working conditions and needs, and the correct installation steps must be followed. Only in this way can the performance advantages of the three-way ball valve be fully utilized and the safety and reliability of the pipeline system improved.

The three-way ball valve is a new type of three-way switching ball valve, which can be used to control the direction, divergence or merging of the media in three pipelines. According to the different ball core structures, it can be divided into T-type or L-type, T-type three-way The difference between a ball valve and an L-shaped three-way ball valve mainly lies in the difference in internal structure. There is no difference in appearance!

The T-type ball valve can connect three orthogonal pipes to each other and cut off the third channel, and play the role of dividing and converging flows, while the L-type ball valve can only connect two mutually orthogonal pipes and cannot maintain the mutual flow of the third pipe at the same time. Connectivity only plays a distribution role.

As can be seen from the picture above, the T-type ball valve is mainly used for diversion or mixing of media, and the L-type ball valve is mainly used for reversing! The L-type three-way ball valve is used for distribution and switching that does not require 3-way. It is more convenient to operate. It has only two valve positions and is positioned. It can be turned 90 degrees without making mistakes. The T-type three-way ball valve has a wide range of channel selections. , there are many valve positions, and generally there is no positioning. If it replaces the L-shaped one, it needs to be rotated 180 degrees.

From a technical point of view, the T-type three-way ball valve can replace the L-type three-way ball valve, but the L-type cannot replace the T-type! During use, different structural forms should be selected according to different working conditions, and the T-type ball valve can flow directly, but the L-type ball valve cannot.