Case

Case

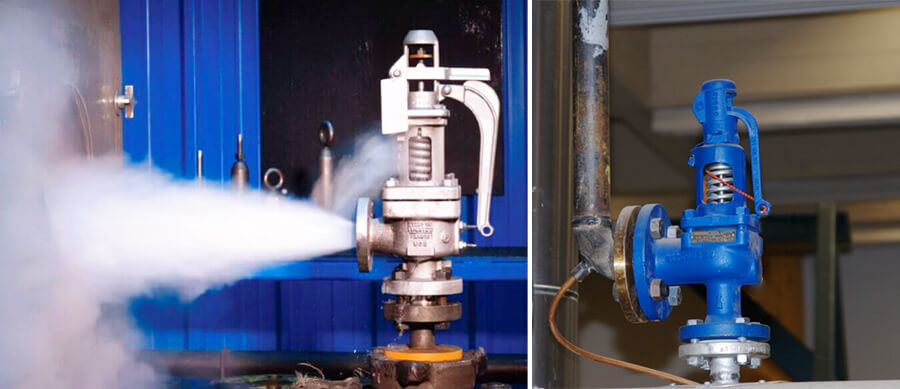

A safety valve is an automatic valve that uses the force of the medium itself to discharge a rated amount of fluid without any external force to prevent the pressure from exceeding the rated safety value .What is a safety valve?

When the pressure returns to normal , the valve closes again and prevents the medium from continuing to flow out. Therefore , safety valves are often used in boilers, pressure vessels, pressurized equipment or pipelines as an over pressure protection device to prevent the pressure in the pressurized equipment from exceeding the design allowable value, thereby protecting the safety of the equipment and its personnel.

The safety valve can act without any external energy source, so it is often used as the last protection device of the pressurized equipment . The performance of the safety valve is related to the safety of power station equipment with an investment of hundreds of millions of yuan, the long-term normal operation of large chemical plants, the safety of flammable, explosive, and hazardous and toxic storage tanks .

All countries in the world have formulated many relevant standards and regulations for the design and manufacture of safety valves. At the same time, the performance of safety valves is not only related to the selection, structure and manufacture of safety valves, but also closely related to the selection, use and maintenance of safety valves.

Due to the different uses of safety valves , there are many types of structures , and they can usually be classified according to the following methods.

Steam safety valve: Usually represented by the A48Y type.

Gas safety valve: usually represented by A4 2Y type.

Liquid safety valve: usually represented by A4 1H type.

Low pressure safety valve: safety valve with nominal pressure ≤ PN16.

Medium pressure safety valve: PN 1 6 < nominal pressure ≤ PN100 safety valve.

High pressure safety valve: PN100 < nominal pressure ≤ PN1000 safety valve.

Ultra-high pressure safety valve: safety valve with nominal pressure ≥ PN1000.

Ultra-low temperature safety valve: t<-100℃.

Low temperature safety valve: - 100℃ ≤ t ≦ -29℃.

Normal temperature safety valve: - 29℃ < t < 120℃

Medium temperature safety valve: 120℃ ≤ t ≤ 425℃

High temperature safety valve: t > 425℃

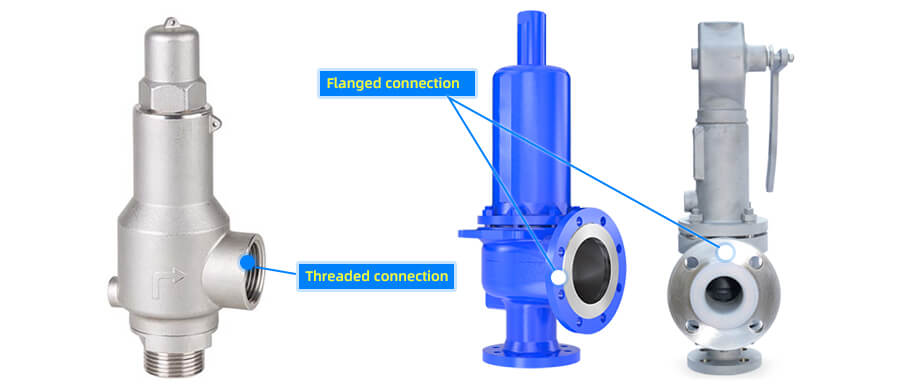

Flanged connection safety valve, threaded connection safety valve, welded connection safety valve.

Metal to metal (hard seal), metal to non-metal (soft seal).

Direct acting safety valve (also divided into direct load safety valve and supplementary load safety valve), of which direct load safety valve can be divided into heavy hammer type, lever heavy hammer type and spring type safety valve .

Indirect-acting safety valve (also divided into pilot-operated safety valve and safety valve with power auxiliary device), among which pilot-operated safety valve is further divided into protruding-opening pilot-operated safety valve and modulation-type pilot-operated safety valve.

Proportional-action safety valve: a safety valve whose opening height changes gradually as the pressure rises.

Two-stage action type (kick action type) safety valve : at first the valve disc opens proportionally with the increase of pressure . Open the safety valve to the specified height.

Micro-opening safety valve: The opening height is within the range of 1/40 ~ 1/20 of the diameter of the flow channel.

Full-open safety valve: a safety valve whose opening height is not less than 1/4 of the diameter of the flow channel.

Middle opening type safety valve: a safety valve whose opening height is between the slightly opening type and the full opening type.

Balanced safety valve, conventional safety valve.

Heavy hammer type or lever heavy hammer type safety valve, spring direct load type safety valve, air chamber type safety valve, permanent magnet type safety valve.

Closed safety valve: The outlet side of the safety valve is required to be sealed. When used for toxic, harmful, flammable and other media , in order to prevent the medium from escaping to the surrounding environment, or to recover the discharged medium, and when there is additional back pressure, a closed safety valve should be used.

Open safety valve: The valve cover of the safety valve is opened, so that the spring is directly connected to the atmosphere, which is beneficial to reduce the temperature of the spring. It is mainly used in air or high-temperature gas that does not cause pollution to the environment, such as water vapor.