Case

Case

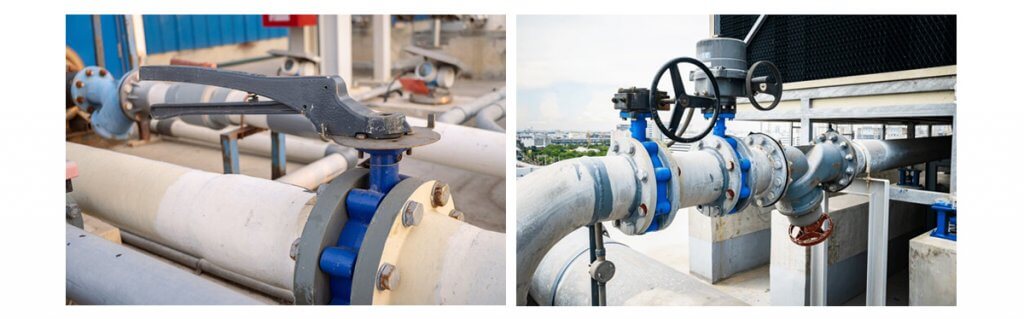

The lug butterfly valve is named for the lugs on both ends of its valve. The lugs of the valve can be fixed to the pipeline to prevent the valve from wobbling or falling off when in use and can also act as a seal.

The sealing performance of the lug butterfly valve is very good, which can prevent leakage, and it also has good flow characteristics with low flow resistance, which will not affect the flow of the pipeline. The lug butterfly valve is widely used in the pipeline system of chemical, petroleum, metallurgy, water treatment, electric power, food, and other industries and is a cost-effective valve product.

The lug butterfly valve can be driven by manual, electric, pneumatic, and other driving methods, which can be selected according to different working conditions. In addition, the lug butterfly valve can achieve two-way sealing; that is to say, good sealing performance can be achieved in both positive and negative directions.

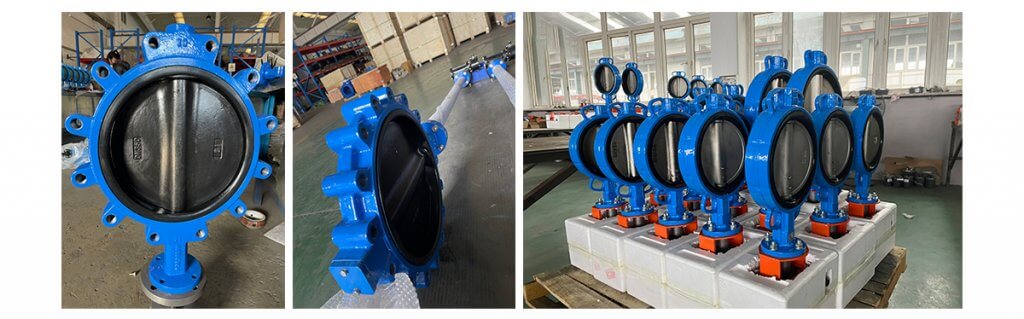

The structure of the lug butterfly valve is relatively simple, consisting of a few parts, making disassembly and maintenance relatively easy and reducing maintenance costs.

The valve disc of the lug butterfly valve adopts the form of a disc, forming a smoother flow channel between the import and export of fluid, and the flow resistance is relatively small when the fluid passes through the valve, so it can effectively reduce energy consumption.

The sealing ring of the lug butterfly valve is made of rubber, PTFE, and other materials, which have good elasticity and corrosion resistance and can achieve two-way sealing, ensuring the pipeline's safe operation.

The operating lever of the lug butterfly valve is relatively short and flexible in operation, and it does not require much force to complete the opening and closing operation. In addition, the opening and closing of the valve can be achieved by a variety of driving methods, such as manual, electric, and pneumatic, which is convenient for automatic control.

Due to the relatively simple structure of the lug butterfly valve, the manufacturing cost is relatively low, and the price is more affordable than other valve products.

The lug butterfly valve is structurally different from a normal pair of butterfly valves. The butterfly valve is sealed by the clamping force between the two valve bodies, and the valve disc is connected to the valve stem by a bolt, which rotates along the valve shaft to open and close. On the other hand, the lug butterfly valve is sealed by the raised ears on the valve disc and the raised lugs on the valve body, and the valve disc is connected to the stem through the bolt and rotates around the valve shaft to achieve opening and closing.

The lug butterfly valve achieves sealing of the valve through the raised ears on the valve disc and the raised lugs on the valve body, which provides better sealing performance.

The lug butterfly valve is more compact and can withstand higher pressure.

The lug butterfly valve has better sealing performance and is suitable for more demanding working conditions, such as high temperature and high pressure.

The operating lever of the lug butterfly valve is relatively short and flexible in operation, so it does not require much force to complete the opening and closing operation.

According to the nature of the medium (such as corrosiveness, viscosity, temperature, etc.), choose the suitable valve body, valve material, and sealing material.

According to the working pressure, temperature, flow rate, and other working conditions, determine the rated pressure, temperature, flow rate, and other parameters of the valve.

According to the diameter of the pipeline, wall thickness, connection requirements, etc., choose the appropriate valve specifications and connection methods.

According to the flow rate, differential pressure, flow rate, and other control requirements choose a suitable adjustment method, such as manual, electric, pneumatic, hydraulic, etc.

According to the maintenance requirements, choose valves that are easy to disassemble, repair and replace seals, etc.

Before installation, the valve must be checked to see if the valve disc, seal, stem, and other parts are intact.

Before installation, you need to check the cleanliness of the pipeline and whether it meets the requirements, such as pipe diameter, wall thickness, flange connection size, etc.

When installing the lug butterfly valve, you must choose a suitable operation and maintenance position.

The lug butterfly valve needs to be installed with attention to the installation direction, and the raised ears on the valve disc need to be installed in correspondence with the raised lugs on the valve body.

When installing the lug butterfly valve, attention needs to be paid to the tightening strength of the flange connection to prevent air leakage or seepage at the flange connection.

After installation, the position and angle of the operating lever need to be adjusted for ease of operation and control.

After installation is complete, a pressure test is required to check the sealing performance of the valve and the normal axial and radial movement of the valve disc.