Case

Case

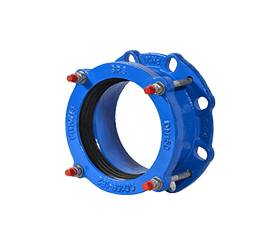

A flange adaptor is an essential component used to connect two different pieces of equipment, such as pipes, valves, or other mechanical systems, that have different flange types, sizes, or specifications. This piece plays a critical role in industries such as plumbing, oil and gas, manufacturing, and chemical processing, where maintaining a secure and efficient connection between systems is vital.

In this article, we’ll dive into what a flange adaptor is, how it works, the different types available, its various applications, and why it’s indispensable for modern industrial and plumbing systems.

A flange adaptor is a mechanical fitting used to join two components—typically pipes, valves, or tanks—that have different flange sizes, designs, or standards.

It typically has flanged ends that match the two components, allowing them to be securely connected with bolts. The flange adaptor ensures a leak-proof and stable connection between these components, making it ideal for situations where direct flange-to-flange connection is not feasible.

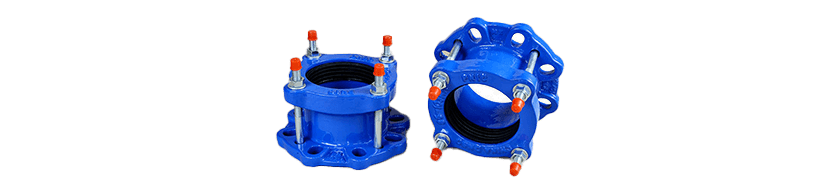

Compatibility: Designed to connect systems with different flange specifications.

Leak-Proof: Ensures tight seals, preventing leaks and system failures.

Durability: Made from strong, corrosion-resistant materials that withstand harsh environments.

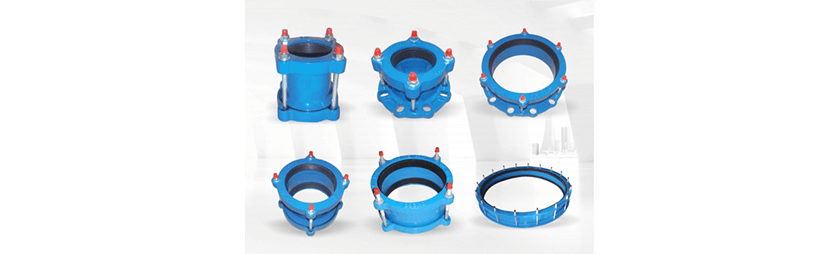

Flange adaptors come in a variety of designs to meet the specific needs of different systems. Below are some of the most common types:

This type of flange adaptor is used to connect pipes with different flange sizes. It reduces the size of the connection, allowing for a smooth transition between larger and smaller flanges.

Application: Used when transitioning between pipes of different diameters, such as in water distribution systems or gas pipelines.

The expanding flange adaptor is the opposite of the reducing type. It is used when you need to increase the size of the flange to connect a larger pipe to a smaller one.

Application: Often used in systems requiring higher flow rates or in areas where increased pressure and volume are needed.

This type features bolted connections on both ends, offering a secure and stable attachment. These adaptors are ideal for high-pressure applications.

Application: Common in industrial settings such as the oil and gas industry, where systems require robust and secure connections.

Designed for systems that require threaded connections rather than bolted ones, threaded flange adaptors are used when the system needs to be disassembled frequently.

Application: Ideal for low-pressure systems or for systems that need to be easily maintained.

Flange adaptors are used in many industries, each requiring them for different types of connections.

Flange adaptors are crucial in plumbing systems for connecting pipes of various materials, such as steel, PVC, or copper, which may have different flange types.

Application: They are commonly used in municipal water systems, residential plumbing, and drainage systems.

The oil and gas industry heavily relies on flange adaptors to connect pipes with differing flange standards. These adaptors ensure safety and efficiency in high-pressure, high-temperature environments.

Application: Used in offshore platforms, refineries, pipelines, and drilling rigs to ensure secure, leak-proof connections.

Flange adaptors are often used in the chemical and pharmaceutical industries where pipes must be connected to tanks, reactors, or other equipment that have varying flange types.

Application: They are essential for maintaining system integrity and preventing contamination in the manufacturing process.

HVAC systems require flange adaptors for connecting air ducts, valves, and other components of varying sizes. They help in controlling air pressure and maintaining consistent airflow.

Application: Used in commercial, industrial, and residential HVAC installations for creating flexible connections between different systems.

In food processing plants, where hygiene and safety are critical, flange adaptors are used to connect different piping systems that transport liquids and gases.

Application: Ensures smooth operations while maintaining sanitary standards in food processing plants.

Flange adaptors offer numerous advantages in systems requiring connections between different flange types and sizes:

Instead of replacing entire sections of piping or equipment, flange adaptors allow for efficient modification of systems, reducing costs significantly.

Flange adaptors are quick and easy to install, reducing downtime in installations and repairs.

Flange adaptors offer flexibility in choosing and replacing system components, making it easier to adapt to changes in the system requirements.

The secure, leak-proof connections provided by flange adaptors improve system safety by preventing leaks that could lead to dangerous situations, especially in high-pressure systems.

Choosing the correct flange adaptor for your system is essential for optimal performance. Here are a few factors to consider:

Ensure that the flange adaptor matches the flange size and type of the two systems you are connecting. Some adaptors are designed to handle specific standards such as ANSI, DIN, or JIS.

Flange adaptors are available in a range of materials such as stainless steel, carbon steel, and PVC. Choose the material based on the system's environment, pressure, and chemical compatibility.

Make sure that the flange adaptor can withstand the pressure rating of your system. Industrial systems, particularly in oil and gas, may require adaptors that can handle extreme pressures.

Depending on your system’s needs, choose between bolted, threaded, or welded flange adaptors. Bolt-on adaptors are common in high-pressure environments, while threaded adaptors are used for easier disassembly.

A flange adaptor is an indispensable part of many piping and mechanical systems, providing a reliable and cost-effective way to connect components with differing flange specifications. With their ability to ensure leak-proof connections, prevent system failures, and offer flexibility in design, flange adaptors are crucial in a variety of industries, including plumbing, oil and gas, HVAC, and chemical processing.

By understanding the different types of flange adaptors and their applications, you can make an informed decision on which adaptor is best suited for your specific needs. Make sure to consider factors like flange size, material, and pressure requirements to ensure your system operates safely and efficiently.