Case

Case

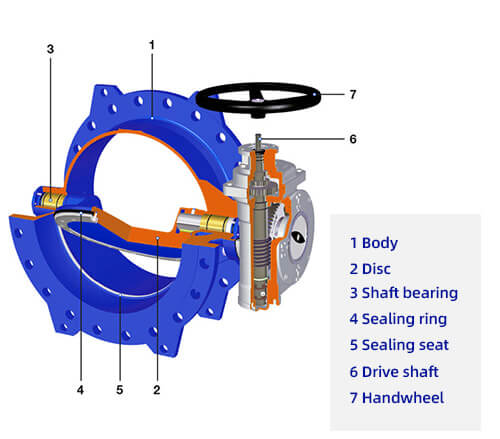

A butterfly valve is a mechanism that regulates the flow of materials within large pipe diameters by the quarter-turn rotation of a disc.

A rod feeds through the center of a disc and this rod is connected to an actuator that controls the motion of the disc. The disc position is either parallel or perpendicular to the flow of media. A butterfly valve differs from other valves because the disc is always in the flow causing a pressure change for any position of the valve.

Sound systems rely on dependable valves. Our butterfly control valve selection is made up of disc valves perfectly sized for various applications and made in precise accordance with industry standards.

The valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, slurry, oil, liquid metal, and radioactive media. The pipeline mainly plays a cutting and throttling role. The butterfly valve opening and closing member is a disc-shaped butterfly plate, in the valve body around its own axis rotation, so as to achieve the purpose of opening and closing or regulation.

The valve body, stem, butterfly plate, and sealing ring are the main components. The valve body is cylindrical, with a short axial length and a built-in butterfly plate.

The valve body fits between the pipe flanges - the most common end connection types being flanged, double lug, and wafer types.

Attached to the valve body is the disc that functions as a gate that stops or throttles fluid flow; it can be considered equivalent to a gate in a gate valve, or a ball in a ball valve. The disc is typically bored to receive the stem, or shaft. There are many variations in disc design, orientation, and material in order to improve flow, sealing, and/or operating torque. For example, Hawle’s 9881k double eccentric disc is designed to reduce seal wear and “scuffing” as well as operating torque requirements.

Lining the internal valve body is a strong elastomer or metal anti-leak seal that secures the disc in place in the closed position in order to achieve complete shutoff. The 9881k series’ stainless steel weld filled and microfinished integral body seat ensures a corrosion and erosion resistant seat face. With this special type of seat design, it is possible to manufacture the valve drop tight according to EN12266 –A requirements.

The valve shaft, often also referred to as the stem, is the component that connects the disc to the actuation mechanism and transmits the torque through itself.

Seals are present at multiple interfaces within the valve to either ensure a tight seal during operation or to isolate the process media from the valve’s internal components for a more flexible and cost-efficient design.

1、Butterfly valve has a simple structure, small volume, light weight, material consumption saving, small installation size, rapid switching, 90° reciprocal rotation, small driving torque, etc. It is used to cut off, connect and regulate the medium in the pipeline, with good fluid control characteristics and closing sealing performance.

2、The butterfly valve can transport mud and accumulate the least amount of liquid at the mouth of the pipeline. Under low pressure, it can achieve good sealing and good regulating performance.

3、The streamlined design of the butterfly plate makes the fluid resistance loss small, which can be considered an energy-saving product.

4、The stem is a through-stem structure, which has been tempered to have good comprehensive mechanical properties and resistance to corrosion and scuffing. When the butterfly valve opens and closes, the stem only makes rotational movement and does not make lifting operation, the packing of the stem is not easy to destroy and the seal is reliable. Fixed with the butterfly plate taper pin, the outer extension is of an anti-flush out type design to avoid the stem crashing out when the stem is accidentally broken at the connection with the butterfly plate.

5、The connection methods are flange connection, butt-clamp connection, butt-weld connection, and lug-to-clamp connection.

The actuators are manual, worm gear, electric, pneumatic, hydraulic, electro-hydraulic, etc., which can realize remote control and automatic operation.

1、Convenient and rapid opening and closing, labor-saving, small fluid resistance, can be often operated.

2、Simple structure, small size, short length of structure, small volume, light weight, suitable for large diameter valves.

3、It can transport slurry and accumulate the least amount of liquid at the mouth of the pipe.

4、Good sealing can be achieved under low pressure.

5、Good adjustment performance.

6、The effective circulation area of the valve seat channel is larger when fully open, and the fluid resistance is smaller.

7、The opening and closing torque is small, because the butterfly plate on both sides of the rotating shaft is basically equal to the action of the medium, and the direction of the generated torque is opposite, so opening and closing is less effort.

8、Sealing surface materials are generally rubber and plastic, so the low-pressure sealing performance is good.

9、Easy to install.

10、Flexible operation, manual, electric, pneumatic, and hydraulic modes can be selected.

By driving mode

(1)Electric butterfly valve

(2)Pneumatic butterfly valve

(3)Liquid-operated butterfly valve

(4)Manual butterfly valve

According to the structure form

(1)Center seal butterfly valve

(2)Single eccentric seal butterfly valve

(3)Double eccentric sealed butterfly valve

(4)Triple eccentric seal butterfly valve

Sealing surface materials are divided into

Soft seal butterfly valve

1) Sealing vice consists of non-metallic soft material to non-metallic soft material.

2)Sealing vice consists of metal hard material to non-metal soft material.

Metal hard seal butterfly valve

The sealing sub is composed of metal hard material to metal hard material

By connection method

Clipped butterfly valve

The butterfly plate of the butt-clamp butterfly valve is installed in the diameter direction of the pipeline. The valve is then fully open.

The butterfly valve is simple in structure, small in size, and light in weight. The butterfly valve has two types of sealing, resilient sealing, and metal sealing. For resilient sealing valves, the sealing ring can be inlaid on the valve body or attached to the butterfly plate periphery.

Flanged butterfly valve

Flanged butterfly valve is a vertical plate structure, the stem is an integral metal hard seal valve seal ring

For flexible graphite plate and stainless steel plate composite structure, installed on the valve body, butterfly plate sealing surface overlay welding stainless steel. The sealing ring of the soft seal valve is made of nitrile rubber and is installed on the butterfly plate.

Lug type butterfly valve

Welded butterfly valve

Welded butterfly valve is a kind of non-closed butterfly valve, widely used in building materials, metallurgy, mining, electric power, and other production processes in the medium temperature ≤ 300 ℃ nominal pressure of 0.1Mpa pipeline, used to connect, open and close or adjust the amount of media.

Butterfly valves as a pipeline system used to achieve the flow control components have been in the petroleum, chemical, metallurgical, hydropower and many other fields of application is extremely widespread.

In the known butterfly valve technology, the sealing form is mostly in the form of a sealing structure, the sealing material is rubber, PTFE, etc. Due to the limitations of structural features, it is not suitable for high-temperature resistance, high-pressure and corrosion resistance, anti-wear, and other industries.

A more advanced butterfly valve is the triple eccentric metal hard seal butterfly valve, the valve body and the valve seat for the conjoined components, the valve seat sealing surface layer welded temperature, and corrosion-resistant alloy materials.

This butterfly valve has the advantages of high-temperature resistance, light operation, frictionless opening and closing, and compensation sealing with the increase in torque of the transmission mechanism when closing, which improves the sealing performance and extends the service life of the butterfly valve.