Case

Case

The flange is also called a flange convex disc or a convex disc. For those who are engaged in mechanical or engineering installation, the flange should be very familiar. It is a disc-shaped part and is generally used in pairs.

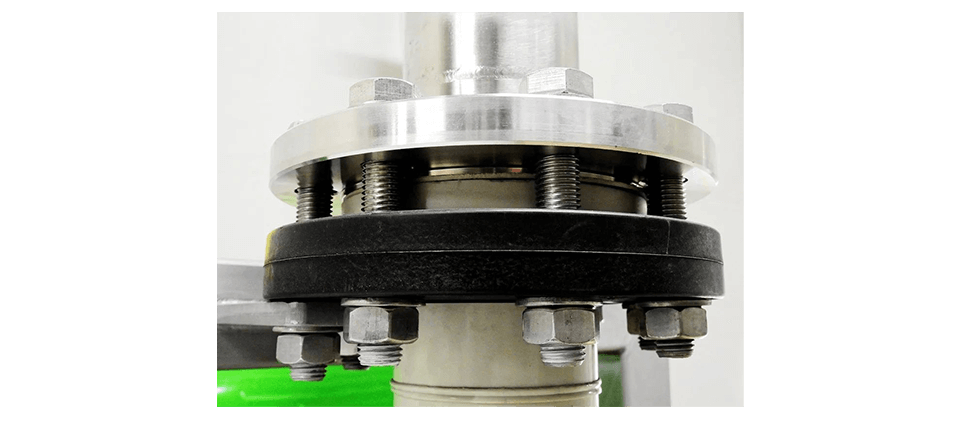

It is mainly used to connect parts between pipes and valves, between pipes and pipes, and between pipes and equipment to serve as seals. Because there are many applications between these equipment and pipes, they are The two planes are connected by bolts and the connecting parts with sealing function are called flanges.

Generally, there are round holes on the flange for fixation. For example, when used at a pipe connection, a sealing ring is added between the two flanges, and then the connection is tightened with bolts. Flanges with different pressures are Different thicknesses and different bolts are used. The main materials used for flanges are carbon steel, stainless steel, alloy steel, etc.

Flange joint is a component that is very commonly used in engineering design and covers a wide range of areas. It is an indispensable part in piping design, pipe fittings and valves, and is also an essential component in equipment and equipment parts (such as manholes, sight glass level gauges, etc.). In addition, other majors such as industrial furnaces, thermal engineering, water supply and drainage, heating and ventilation, automatic control, etc. also often use flange joints. Due to its important role and good overall performance, flanges are widely used in chemical, petrochemical, fire protection, drainage and other industries.

Forged steel, WCB carbon steel, stainless steel, 316L, 316, 304L, 304, 321, chromium molybdenum steel, chromium molybdenum vanadium steel, molybdenum titanium, rubber lined, fluorine lined materials.

Flat welding flange, neck flange, butt welding flange, ring connection flange, socket flange, and blind plate, etc.

There are GB series (national standard), JB series (machinery department), HG series (chemical industry department), ASME B16.5 (American standard), BS4504 (British standard), DIN (German standard), JIS (Japanese standard).

There are two main international pipe flange standards, namely the European pipe flange system represented by German DIN (including the former Soviet Union) and the American pipe flange system represented by American ANSI pipe flanges.

As a kind of connector, flange is widely used internationally, which requires unified standards. For example, there are two main standard systems for pipe flanges.

They are the European pipe flange system, that is, the European pipe flange system represented by German DIN (including Russia), and the American flange system represented by the American ANSI pipe flange.

In addition, there is Japan's JIS pipe flange system, and China also has the steel pipe flange system GB, but the main dimensions are still based on the European system and the American system.

The structure of the flange is relatively simple. It consists of upper and lower flange pieces, a gasket in the middle, and several bolts and nuts.

From the definition of flanges, we can know that there are many types, and their classification needs to be distinguished from different dimensions. For example, flanges can be divided into integral flanges, flat welding flanges, and butt welding flanges according to the connection method. Loose flanges and threaded flanges are also common flanges.

Integral flange (IF) is generally used in pipelines with high pressure. It is a flange connection method and has a long neck. It is usually formed by one-time integral casting, and the materials used are generally carbon steel and stainless steel. etc.

Flat welding flange is also called tower welding flange. It refers to the welding method when connecting to the container or pipeline. This flat welding flange has the characteristics of easy assembly and low price. It is mainly used for pressure and The vibration is relatively small in the pipeline.

The biggest difference between butt welding flange and other flanges is that it has a protruding high neck. The wall thickness of the protruding high neck will gradually match the thickness of the pipe wall to be butted with the height. Like the diameter, this will increase the strength of the flange. Butt welding flanges are mainly used in places with large environmental changes, such as pipelines with high temperature, high pressure and low temperature.

This type of flange is mostly used on some non-ferrous metal and stainless steel pipes. The connection is also achieved by welding. Because it can be rotated to easily align with the bolt hole, it is often used in Large-diameter pipes and joints that often need to be disassembled, but loose-set flanges do not have high pressure resistance, so they can only be used to connect low-pressure pipes.

There are threads in the flange of the threaded flange, which requires that the internally connected pipes also have external threads to achieve connection. It is a non-welded flange, so compared with other welded flanges, it has the advantage of easy installation and disassembly. Threaded flanges are not suitable for use in environments with extremely high or low operating temperatures, because the threads are prone to pipeline leakage after thermal expansion and contraction.

As a connecting and sealing component, flanges will leak if there are quality problems during the production process, causing economic losses, environmental damage and even safety accidents. Therefore, the welding and production of flanges are very important.

At present, there are two main production processes for flanges: forging and casting. Let’s take a look at these two main production processes and see what the differences are between them.

Forged flanges are hammered countless times by a forging machine to make the internal structure of the steel tighter, so the mechanical properties will be better and the strength will be higher. The forged flanges are mainly suitable for pipes with high pressure.

First, the cylindrical steel billet is cut to a certain size, heated to a certain temperature to make it thermoplastic, and placed on a cold heading so that the forging machine continuously beats the billet to make the inside of the billet tighter and improve its mechanical properties. Much better than the original billet.

The circular hole on the flange must be punched out on the steel billet by a stamping machine. The formed blank flange must be placed in an electric furnace for heat treatment to increase the strength of the flange. Finally, the flange blank must be cut and polished into a usable flange.

Cast flanges have the characteristics of low manufacturing cost and high efficiency, and can produce flanges with relatively complex shapes. Cast flanges are mainly suitable for pipes with low pressure.

Casting flanges is also a commonly used manufacturing process. The metal is melted into liquid molten steel, and the molten steel is poured into a metal mold that is preheated and maintained at a constant temperature to form the shape of the flange. After the casting is naturally cooled and formed over a period of time, Then use water to quickly cool down and demould, which can also increase the strength of the flange. Finally, it can be used after polishing and anti-rust treatment.