Case

Case

In the water delivery system, if gas exists in the pipelines, it will not only cause pipeline corrosion, water meters to run dry and other problems, but also make harsh noises, affecting people's rest and work, especially late at night when people are quiet. In more serious cases, if there is too much gas in the water, it will affect the flow of water, and in severe cases, it will block the flow of water! Therefore, the influence of gas in water cannot be underestimated.

① Direct air intake: air intake into a pipe that is not initially filled with water or when the pipe is vented during use.

② Inlet of free state air. For example, the pipeline inlet, negative pressure pipeline system or equipment is not tightly sealed, and when negative pressure is formed in the pipeline system, air enters from the CARX exhaust valve, exhaust pipe, etc.

③ Air released when dissolved in water. There are 2% dissolved air in clean water and 3% in sewage.

Although the gas entering the pipeline is under the same pressure as the transported liquid. However, due to the difference in gravity between gas and liquid and the surface tension of the liquid, gas generally appears at the commanding heights in the pipeline. These tiny bubbles gather together and gradually form large bubbles or even air pockets. Under the combined action of gravity and water flow momentum, these air pockets are either dispersed at the top of the pipeline on a gentler downhill slope (for water flow), or at the bulges of the undulating pipeline.

The position of the bubble in the pipe depends on the balance of its forces. When the axial component of the pipe with poor bubble severity is consistent with the direction of the water flow, the bubbles will advance with the direction of the water flow; otherwise, the bubbles will be retained on the pipe wall or even flow in the opposite direction due to friction. Therefore, the gas in the uphill pipe is easier to discharge, while the gas in the downhill pipe is not easy to be discharged with the water flow.

① Increasing the friction bubbles along the way will increase the flow volume of water, and the relative flow rate between water and the pipe wall will increase, that is, the friction head loss will increase, the water pump head will increase, and the water output will decrease.

② Increase the local resistance and the bubbles gather to form air bags, which reduces the cross-section of the pipeline and increases the water head loss. When air resistance is formed, the water pump cannot even discharge water according to the designed flow rate; when the pipeline has large fluctuations along the way, multiple large drops of water are formed. , multiple top air resistance height differences are superimposed, making it difficult to discharge water when approaching or reaching the pump head, or even no water is discharged from the pipeline terminal outlet.

③ Results in pipeline water pressure test distortion. For example, pipelines with DN400 and below are not tested for water leakage, and only the lOrnin drop pressure is not greater than 5m. When the pipeline exhaust is not clean, the air is compressed during the pressure test process, although the pipeline leakage is large. , but it is compensated by the volume expansion of a large amount of compressed air, and the pressure drop is not large, which cannot truly reflect the pipeline sealing performance.

Single-port Exhaust Valve (exhaust valve) used in independent heating systems, central heating systems, heating boilers, air conditioning, floor heating and solar heating systems, such as pipeline exhaust.

Because air is usually dissolved in water, and the solubility of air decreases as the temperature increases, so as the water circulates, the gas gradually separates from the water, and gradually coalesces to form large bubbles or even gas columns, gas is often produced because of the water supply.

(1)The float of the exhaust valve is made of low-density PP material which will not deform even if it is immersed in high temperature water for a long time.

(2)It won’t make it difficult to move the pontoon.

(3)The float lever is made of hard plastic, and the connection between the lever and the float and the support is movable, so it will not corrode in long-term operation, resulting in the system not working and water leakage.

(4)The seal end face part of the lever is supported by a spring, which can expand and contract correspondingly with the movement of the lever to ensure the sealing under the condition of no exhaust.

Compound exhaust valve body is in the shape of a barrel, and its interior mainly contains Group B stainless steel balls, rods and plugs. Main specifications: Divided into integral single ball type, separate type, integral double ball type composite exhaust valve, pressure level: PN10, nominal diameter: DN25-300mm (DN25 is threaded type, others are flange type).

Compound exhaust valve is installed at the water outlet of the pump or in the water distribution pipeline. Under normal operation of the pipeline, when the air above the valve cavity accumulates to a certain extent, the auxiliary float should drive the sealing surface away from the micro-drainage hole to perform micro-discharge. Exhaust, so that the accumulated air can be eliminated in time;

when water is released from the pipeline or negative pressure suddenly appears in the pipeline, the air valve plug will quickly open and a large amount of outside air will be sucked in to avoid damage caused by negative pressure water hammer in the pipeline and ensure pipeline safety.

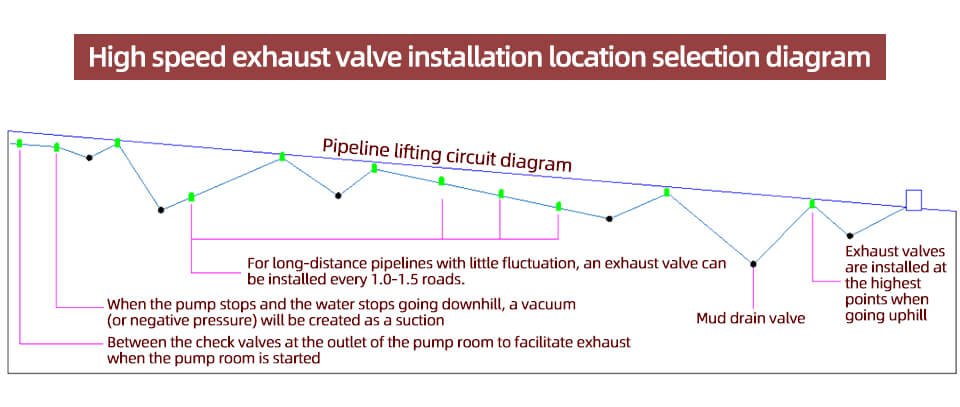

① It is often set up in the pipeline to create raised points (highest points) for gas storage, elbows, tapered pipes, horizontal pipe sections and relatively flat reverse slope pipe sections, etc.;

The point where the downward slope becomes larger;

The point where the upward slope becomes smaller;

Long-distance ascending or descending pipelines without break points are located every 500-1000 meters;

Long-distance horizontal pipelines are located every 500-1000 meters.

In order to discharge the gas in the pipe as soon as possible without forming an air bag, an exhaust valve should also be installed at the downhill section of the water pipeline and at the intersection of the downward curved pipeline and the straight pipeline.

② The harm of water hammer in long-distance water pipelines is extremely destructive. Although the air bag in the pipeline cannot directly cause water hammer, it can cause harm with the help of water hammer. Therefore, for long-distance pipelines, it is best to use water hammer in shorter distances. Install a larger number of exhaust valves with smaller diameters inside instead of installing exhaust valves with large diameters, small numbers, and long distances.

③ Conduct a general survey of the current installation of exhaust valves, replace the exhaust valves on the constructed water pipelines based on actual conditions, and add exhaust valves to individual locations.

① First of all, we must pay attention to the particularity of the exhaust valve in the water pipeline. Based on the structural form and technical performance of the exhaust valve, a product whose performance can meet the needs of the project is selected, and qualified exhaust valve products that meet the corresponding national standards are selected.

② Through experimental measurements, it is ensured that the exhaust valve used can achieve high-speed exhaust that meets the needs of the project in any state of the pipeline, and should have the slow closing function.

③ When choosing to purchase an exhaust valve, you should not only consider the price factor. Do not save tens of thousands of yuan when purchasing materials. If the water pipe bursts during the long-term operation, this loss will be several times or several times the cost saved. ten times.