Case

Case

As the weather gets colder, the demand for heating rises as well. The efficiency of heating pipes and systems depends largely on the correct choice of valves.

Do you know how to choose the right valves for heating equipment? Selecting suitable valves not only ensures smoother system operation but also distributes warmth more evenly and conserves energy. Here’s a detailed guide on valve installation standards and selection criteria in heating systems, helping you manage winter heating with ease!

Valve Installation Standards in Heating Systems

1.Heating Risers in Multi-Story Buildings:

In multi-story buildings, heating risers should be equipped with regulating or shut-off valves to enable tiered control for each floor, ensuring balanced water flow and consistent temperatures. However, it’s not recommended to install valves on risers located in stairwells, as stairwells are common areas and don’t require individual control, reducing the complexity of operation and maintenance.

2.Vertical Single-Pipe Systems (Five Floors or Higher):

In vertical single-pipe systems with more than five floors, a three-way regulating valve should be installed on the supply branch of each radiator. This setup allows for more balanced heat distribution, preventing insufficient or excessive temperatures on higher floors and achieving optimal heating on each floor.

3.Temperature Control in Double-Pipe Systems:

In double-pipe systems, if precise temperature control is required, a thermostatic control valve can be installed on the radiator supply branch. This type of valve adjusts the water supply based on room temperature changes, keeping the room at a constant temperature, providing a more comfortable environment, and reducing energy consumption.

4.Horizontal Single-Pipe Systems (Cross-Over):

For horizontal single-pipe crossover systems, if specific room temperatures are required, a valve can be installed on the radiator supply branch to adjust the temperature in each room, ensuring more even heating.

5.Valve Installation on Main Pipelines:

Each loop’s main pipeline inlet and outlet, as well as the entire system’s main inlet and outlet, should have valves installed. This design facilitates efficient shut-off and sectional control during maintenance, minimizing the impact on the entire system’s operation.

6.Shut-Off Valves on Branches:

If parts of the system need to be stopped for repairs, shut-off valves should be installed on each branch main. This enables independent shutdowns for specific areas, avoiding system-wide shutdowns, enhancing maintenance flexibility and operational convenience.

Note: To prevent freezing during winter, the distance from the valves on risers or branches to the main pipeline should not exceed 120mm. This ensures that even in low temperatures, the residual water won’t freeze within the pipes.

Valve Selection Criteria in Heating Systems

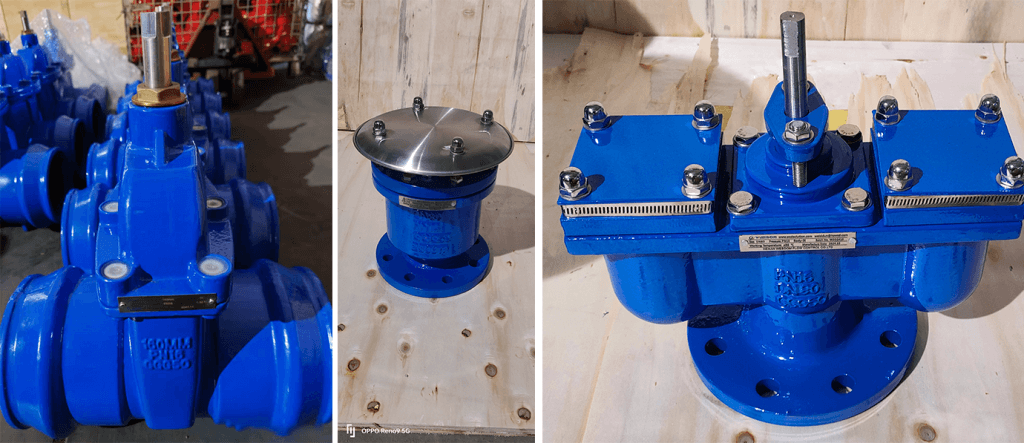

Globe Valves:

For shut-off operations in the heating system, hot water systems typically use WEIZIDOM gate valves or ball valves. These valves are simple in structure, provide excellent sealing, are easy to operate, and are durable, especially suitable for high-temperature and frequent-use scenarios.

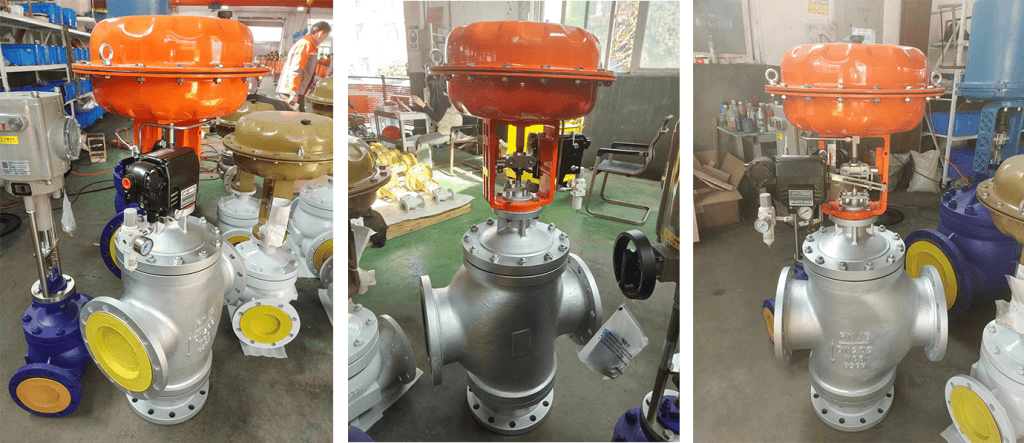

Regulating Valves:

For parts of the system where water flow needs to be adjusted, it’s recommended to use globe valves, wafer-type butterfly valves, or specialized regulating valves. These valves allow precise control of flow and can be fine-tuned without shutting down the system, meeting actual heating demands.

Drain Valves:

When the system needs to be drained during shutdown or maintenance, plug valves or WEIZIDOM gate valves are recommended. Plug valves are compact and allow for quick drainage, while WEIZIDOM gate valves are ideal for high-volume drainage, speeding up the process.

Air Release Valves:

Air trapped in the system affects water flow and heating efficiency, so it’s essential to install air release valves at high points or critical locations. Common air release valves include thermostatic automatic air release valves, automatic air release valves, key air release valves, plug valves, or manual venting valves. These valves discharge trapped air as needed, ensuring smooth circulation.

Summary

The installation and selection of valves in heating systems should be adapted based on the building structure, heating method, and specific user requirements. Proper valve installation and regular maintenance can not only extend the system’s service life but also improve energy efficiency and reduce costs, delivering a more comfortable and effective heating experience during winter.