Case

Case

Globe valve, a relatively common valve in life, can often see its figure in our projects. Although common, but many friends do not know much about it, in the time of self-installation, but there will be some problems, so that it does not take long to have problems, but also continue to replace, and even complain about the quality of the valve is not good, leading to so many misunderstandings, it is not right.

In view of this situation, the contents of this issue, with you about the knowledge of the globe valve, so that we have a clear understanding, so that the installation of their own unnecessary trouble.

Globe valve, also known as forced closed valve, the so-called "forced" means that when the valve is closed, you need to apply pressure to the valve flap, forced pressure on the fluid, to play a role in cutting off the fluid. The pressure is generally applied in the form of a spiral lift, turning the valve handle, the valve stem down, driving the valve flap, so that the sealing surface in the form of pressure on the sealing surface of the valve seat, sealing the flow of fluid. This is also the principle of its operation.

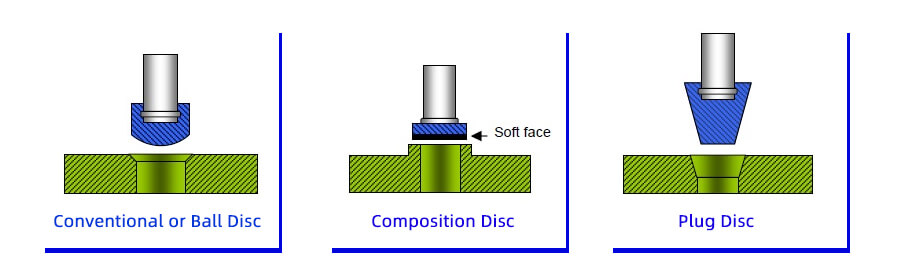

The valve flap of the globe valve can be made into a plug type, and the sealing surface can be made into a cone, so that the spiral lift of the valve stem drives the valve flap, it can realize the function of controlling the flow of fluid, with good fluid flow regulation function. And this kind of valve opening and closing formation is relatively short, with a good cut-off function.

Therefore, this kind of valve is widely used, water, gas, steam, oil and other fluid media in the project. Can be used for both regulation and cut off, very suitable.

In addition, the globe valve itself does not produce friction with the valve body, so it has a better sealing performance and a longer service life, which is its advantage. Of course, because it needs to belong to the forced closed valve, its opening and closing torque is relatively large, it is difficult to achieve rapid opening and closing, and the internal channel of the valve body is relatively tortuous, there is a relatively large resistance, will cause fluid power loss, which is its disadvantage.

The above is about the working principle, function and related advantages and disadvantages of the globe valve, to give you a brief understanding, in fact, we live, encounter the most or its installation and use. Now we will continue to introduce it to you.

Globe valves are commonly used in various industries, especially in situations where precise flow control is required. Here are some application cases for globe valves:

#1 Water treatment plants - Globe valves are often used in water treatment plants to control the flow of water and other liquids through pipes, ensuring accurate and precise regulation of the water flow rate.

#2 Petrochemical processing - Globe valves are used in petrochemical processing to regulate the flow of fluids such as oil, gas, and chemical solvents, and to provide precise control over the rate of chemical reactions.

#3 Power generation - Globe valves play an important role in power generation systems, where they are used to control the flow of steam and other fluids in boilers and turbines.

#4 HVAC systems - Globe valves are used in heating, ventilation, and air conditioning (HVAC) systems to control the flow of water and other fluids through pipelines, and to regulate the temperature and pressure of the fluid.

#5 Oil and gas industry - Globe valves are widely used in the oil and gas industry to regulate the flow of crude oil, natural gas, and other fluids. They are used in offshore drilling rigs, refineries, pipelines, and other areas of the industry.

Overall, globe valves are versatile valves that are widely used in various industries and applications, providing precise and reliable flow control.

About the installation of the globe valve, is not complicated and other types of valves, leave the appropriate size, according to the interface, is a fillet connection of the fillet connection, is a flange connection in accordance with the requirements of the flange connection, and nothing special. However, at the time of specific installation, the following three matters should be noted.

The globe valve is directional and must be installed in accordance with the correct direction. Generally, it has a directional arrow mark on the valve body, we can install it in accordance with the direction of fluid flow and the direction of the arrow. If there is no arrow mark, the direction can be determined according to the principle of "low in high".

If the valve body can not visually determine the import and export height, you can look at both ends of the valve interface, feel it with your hands, up is the export, straight through is the import. This directionality is important, do not install the reverse.

If the handle and handwheel type globe valve, when installed, do not deliberately require horizontal or vertical installation, the orientation of the handle is not required, as long as it is easy to operate, the location is appropriate, can be installed. For self-acting globe valves, such as automatic globe valve for gas, there is a horizontal installation, the handle facing upward a requirement, mainly to consider the impact of gravity, more sensitive.

According to the principle of opening and closing the globe valve, its handle in the open state is elongated, closed when it is shortened, so the installation, be sure to pay attention to the handle not only to reserve space for operation, should also consider the handle of the vertical lifting space to prevent the normal opening and closing of the valve.

This is some of the installation requirements of the globe valve, which is more controversial, but also the most likely to appear is the direction of installation, some friends will ask, if the direction of the globe valve is installed incorrectly what will happen? This does have a certain impact.

What problems will exist if the direction of the globe valve is installed in the opposite direction?

As a globe valve, it is required to install in the direction of the instructions, if installed in the opposite direction, the following may occur.

According to the structure of the globe valve, we can see that the internal channel of its valve body is similar to a lying flat "S" type, and the valve is in the middle of the S-shaped position, the two channels in two, in the closing time is forced to make the valve valve pressure seat to achieve sealing. This is only the lower part of the fluid with pressure, so that it is easier to open, and if the reverse, the upper part of the pressure, the pressure will give the valve valve a force tightly pressed valve, open the time is more difficult.

Also according to the structure of the globe valve, we can see that the main seal of the globe valve is in the upper part, including the seal at the stem and the seal at the bonnet, if the flow from the top down, when the valve is closed, that is, the upper part has been in a state of pressure, once the valve is not sealed tightly, is in the closed valve state, or will leak outward. And the opposite direction, there is no such concern.

I believe that friends know that we pipeline conveying some fluids, such as water, its internal may have some sediment, rust and other dirt. According to the structure of the globe valve, if the valve is flowing from top to bottom, due to the factors of the valve flap, sediment, dirt is likely to gather in the upper part of the valve flap, or even the valve stem and the entire upper cavity, because the valve flap and the valve stem is moving up and down, so these attachments will impede the up and down movement of the valve flap, and even can not switch the valve normally.

In order to make the globe valve work properly for a long time, we should understand the daily operation and maintenance of it. There are the following matters we need to understand.

1.Opening and closing operation method. Normal globe valve facing the handle, clockwise direction for the globe valve to close or turn down, counterclockwise direction to open or increase the adjustment.

2. Do not use too much force when fully open the valve. General globe valve fully open, the valve handle can not rotate, indicating that the stem has been completely rotated out, if you use brute force, may cause damage to the globe valve button, affecting the normal use of the valve. The correct method is to open slowly, when the rotation is more laborious, slightly back to complete the operation.

3. The use of high-speed fluid to flush the dirt in the valve body. If the globe valve is open for a long time, there may be some dirt attached to the valve flap and sealing base, resulting in the valve not closing tightly, in this case, we can try to adjust the globe valve to the minimum flow state, the use of high-speed fluid, the dirt will be flushed away, and can be repeated. This is also a daily solution to the globe valve does not close tightly operation method.

4. Press down the valve handle to assist in closing the valve. When the delivery fluid pressure is not good to close the globe valve, we can try a little force to the valve handle a longitudinal force, but pay attention to the strength, so that it is easy to close the valve.

The above is all the content of today's science and technology about the globe valve. Finally, to summarize, the globe valve is a forced closed valve, its installation needs to pay attention to the directional, in accordance with the arrow mark for installation.

If not installed in accordance with the requirements, installed in reverse, will lead to the valve open more difficult, affecting the valve body sealing and service life and can not be properly opened and closed. In order to be able to better use the globe valve, the last to explain to you about the operation of the globe valve four methods. Hope to bring some help to you.