Case

Case

It’s all about the point! Selection and application control of large-diameter water meters

Large-diameter water meters usually refer to water meters with a nominal diameter greater than DN50. They are mainly used for trade settlement measurement for industrial and commercial users, zonal measurement (DMA) of pipe network systems, and water measurement for fire protection, gardens, etc.

Although the proportion of large-diameter water meters is small, the total amount of water measured is usually more than twice the total amount of household water meters, and even up to 4 times in industrially developed areas. Therefore, the measurement benefits of large-diameter water meters play a vital role in a region's water management and control of production and sales differences.

Existing large-diameter water meters realize flow measurement based on measuring water flow velocity, so they are called velocity water meters. Assuming that the area is known, the product of the flow rate and the flow rate is the flow rate. The flow rate is integrated over time to obtain the total volume of water. The smaller the pressure loss of the velocity water meter, the greater the circulation capacity, which is more conducive to controlling the energy consumption of water transportation in the pipe network.

The element used to sense water flow velocity in horizontal and vertical propeller water meters is a spiral rotating impeller.

The impeller rotation axis of the horizontal propeller water meter is the same as the central axis of the pipe and is arranged horizontally. The impeller rotation axis of the vertical propeller water meter is perpendicular to the center line of the pipe axis and is arranged vertically.

In recent years, the impeller of the horizontal screw-wing water meter has been designed to be lightweight by using high-strength engineering plastics to achieve a wider measurement range, and the rotation axis can be tilted or installed vertically. In order to distinguish it from the traditional horizontal screw-wing water meter, it is called It is a turbine water meter.

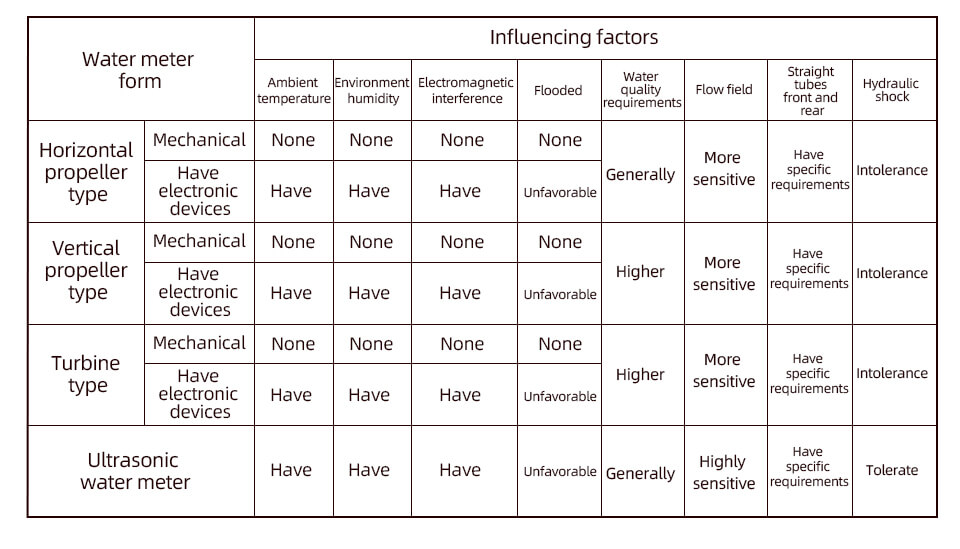

The mechanical counting mechanism of horizontal screw-wing and vertical screw-wing water meters is replaced by an electronic counter, which is a mechanical sensing electronic water meter. Since mechanical sensing electronic water meters have no transmission resistance, they have better measurement lower limit capabilities. Coupled with electronic correction technology, they can achieve better measurement characteristics than mechanical water meters.

The ultrasonic water meter is based on the working principle of the ultrasonic propagation time difference method between downstream and countercurrent. The time difference is approximately proportional to the water flow velocity.

Unlike household ultrasonic water meters, large-diameter ultrasonic water meters can be installed with multiple sound channels, which can greatly improve metering performance and better reduce sensitivity to flow field distortion. The more sound channels there are, the better the measurement performance of the ultrasonic water meter.

The impeller of the mechanical sensing water meter is driven by the water flow to rotate. The advantage is that the sensing end responds to stress and does not need to consume electrical energy. The disadvantage is that the mechanical movement is affected by resistance from the fluid and transmission, so there is a theoretical lower limit for measurement. The working mechanism of the sensing end of the electronic sensing water meter is excitation response. The sensing excitation signal of the ultrasonic water meter is ultrasonic wave.

The sensing excitation signal of the electromagnetic water meter is a magnetic field, which requires the consumption of electrical energy to generate. The advantage is that the theoretical measurement lower limit is zero, which can be achieved A very wide measurement range. In fact, due to the existence of external interference and internal noise, there is still a lower measurement limit limited by the current technical level.

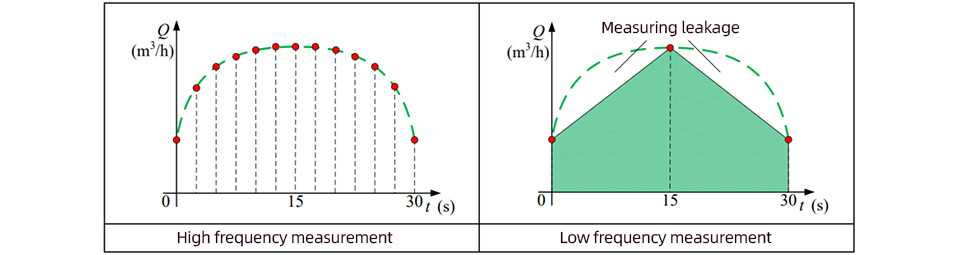

Electronic sensing electronic water meters usually use built-in battery power supply and low power consumption design. The advantage is that the circuit thermal noise is small and can achieve a measurement range much larger than that of mechanical sensing water meters. The disadvantage is that it usually uses intermittent operation in order to save power and extend battery life. Measurement mode. When the frequency of intermittent measurements is low, significant measurement errors are likely to occur in situations where the flow changes rapidly, as shown in Figure 1 below.

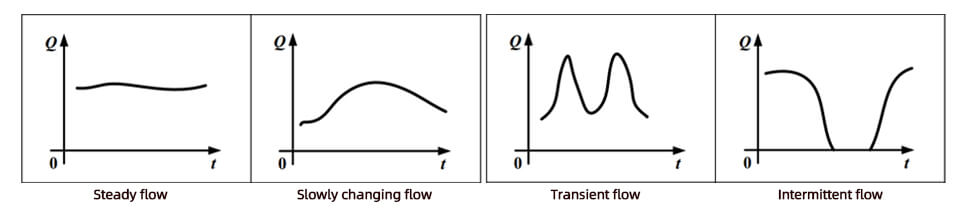

Water usage conditions refer to the changes in water flow in pipelines under normal production and living conditions. It can usually be described by the relationship curve between flow and time.

① Stable flow, the flow rate does not change significantly with time.

② Slowly changing flow, the flow rate changes slowly with time.

③Transient flow, the flow rate changes rapidly in a short period of time.

④ Intermittent flow, the flow is on for a period of time and then stopped for a period of time, repeating the cycle.

Through the analysis of water usage conditions, it is possible to roughly determine the peak and valley flow and water proportion of users' water use in various periods, which facilitates the selection of water meter types based on the performance indicators of the water meter. In principle, the measurement range of the water meter should cover the minimum flow rate and the maximum flow rate of the working flow, and the flow rate during the main water use period should fall above the water meter boundary flow rate.

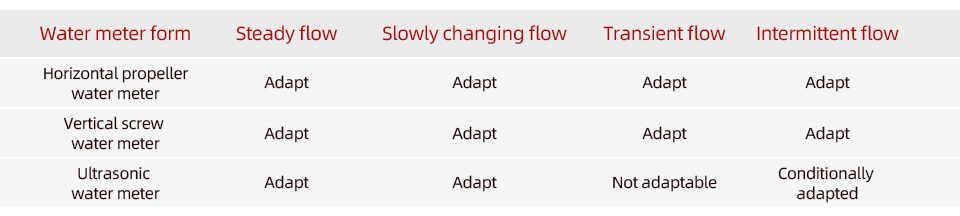

Different types of water meters have different adaptability to the above four working conditions, as shown in the table below.

Different types of water meters have different characteristics. During the selection process of large-diameter water meters, it must be recognized that only when the water meter type matches the characteristics of the working flow can the measurement characteristics of the water meter be exerted. Mismatching the type will inevitably lead to inaccurate measurement.