Case

Case

The sealing failure of the blind flange sealing joint produced by the flange manufacturer is mainly manifested in leakage. In pipeline systems and devices in various industries, the sealing failure of flange joints can cause a lot of waste of energy and raw materials. If it is more serious, it will lead to scrapped equipment, shutdown of production, casualties and serious environmental pollution.

Therefore, modern petroleum, chemical, petrochemical, atomic energy, aerospace and other industries have put forward higher requirements for the sealing of pipeline devices. Flange joint is a kind of detachable connector, and it is also a product with high sealing requirements. The key is in the sealing material, the quality of the sealing material is directly related to the sealing quality of the flange product. It can be said that although the gasket is small, it is related to the problem of the sealing failure of the flange.

Generally, the bearing weight of blind flange is relatively large, and it is generally not easy to deform during engineering. The key is the thickness problem. The inner and outer diameters of large flanges are not a problem on the production side. The worst thing to do is their thickness. If the blind flange is too thin, it will be easily deformed. Of course, there is generally no deformation problem during the production process, and it will not occur when it is processed by the machine tool, but it is dangerous during use.

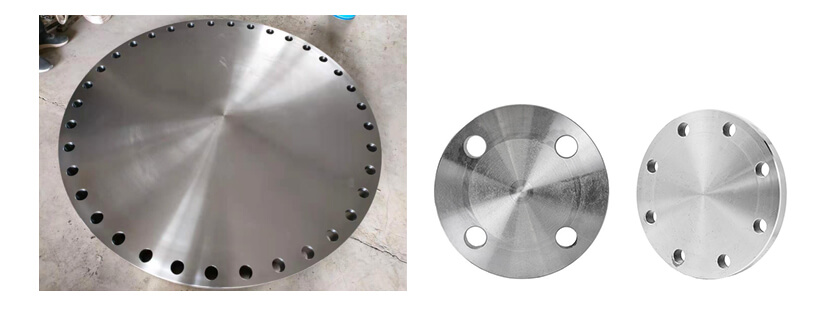

Blind flanges are cut into strips with medium plates, and then rolled into circles. Waterlines, bolt holes, etc. are then processed. This is generally a blind flange, and the maximum can be 7 meters. Such flanges have a very good quality guarantee. Because the raw material is medium board, the density is good. Materials are carbon steel, stainless steel, alloy steel, etc.

Blind flange production process characteristics: The products of large flanges are all welded products without threads. There are three types of blind flange production processes: forging, rolling and splicing. First cut the middle plate into suitable slivers, the length of the sliver is determined according to the specifications of the large flange. Then use a ring rolling machine to make a circle, and use a welding rod to weld the joint firmly, and X-ray spectrum inspection should be carried out at the welding joint. Then use the press to flatten it, and then use the lathe to process the water line, chamfering and other processes, and finally use the indexing plate to cooperate with the drilling machine to punch the bolt holes.

The formal name of flange blind is called flange cover, also some called blind flange or pipe plug. It is a flange without a hole in the middle, mainly used to seal the front end of the pipe, for sealing the mouth of the pipe. Its function is the same as that of the head and tube cover, except that the blind seal is a removable sealing device, and the seal of the head is not ready to be opened again.

Flange blind materials are carbon steel, alloy, stainless steel, plastic, etc. Flange blind plays the role of vibration isolation, cut off, sealing head and pipe cover function the same, because its sealing performance is good, for the need to completely isolate the system, generally used as a means of constant vibration isolation, blind is a solid genus with a handle, generally used to isolate the state system in general. It is more convenient to use the flange blind, need to be separated, use the blind end, need to operate normally, use the throttle ring yellow, and can also be used to fill the installation gap of the blind on the pipe. Also, flanged blinds are clearly marked, and easy to identify the state of installation.

A flange, also known as a flange or raised edge, is a component that connects pipes, usually at the end of a pipe. The flange is perforated, and when connecting, bolts are required to fasten the two flanges. The flange is sealed with a gasket, which acts as a seal or, in the case of experiments, as a temporary break. Flanges are the more common disk parts in pipeline engineering. In general, flanges are used in pairs. According to the different ways of connection, the flange is divided into threaded connection flange, welded flange, and clamping flange. Low-pressure pipelines can use threaded connection flanges and welded flanges for pressures above four kilograms.

(1) the application of the flange - because the flange has good performance characteristics, so it is widely used in chemical, construction, petroleum, health, pipeline, fire, and other basic engineering.

(2) In the pipeline strength test or seal test, it cannot be applied at the same time as the connected equipment (such as turbine, compressor, gasifier, reactor, etc.) in the blind - original start-up preparation stage. A blind connection of the equipment to the pipeline is necessary. Various process material pipes connected to boundary areas beyond the boundary area should have a blind at the shut-off valve when the equipment is stopped and if the pipe is still running.

WESDOM blind flanges are ready shipment to Kingdom of Saudi Arabia! Good quality will well ensure the safety of your project. Welcome to inquiry from us!