Case

Case

The butterfly valve is one of the commonly used valves in the water treatment system, and its main function is cutting off and throttling. When the butterfly valve is used for cutting, the elastic seal is used, the material is rubber, plastic, etc., and when it is used for throttling, the metal is used for hard sealing.

Mididle line to clamp butterfly valve

Double flange butterfly valve

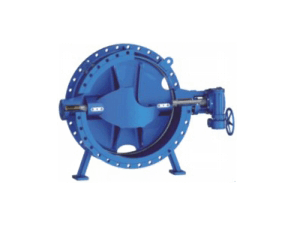

Double eccenntricflange butterfly valve

U type butterfly valve

Double flange electric soft seal butterfly valve

Anti-knot dew butterfly valve

Double flange electric soft seal butterfly valve

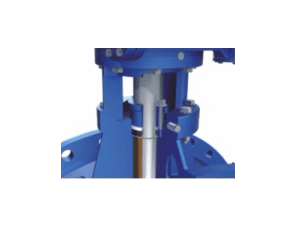

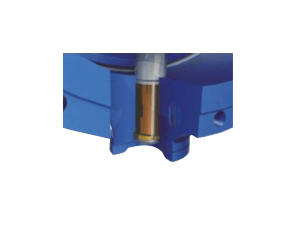

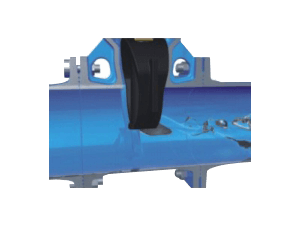

The reliablity of top seal has been enhanced by using the double sealing of "O" ring and "V" rings. The "O" ring is located between the stem and the body to ensure the first sealing performance. The second seal is combined by V-shaped seal rings which achieve sealing requirements by the extrusion of the gland.

There is yoke between the body and operator. Once the leakage occurs in the top, the valves can be repaired without taking apart the gear-boxes or actuators. In this case, we iust need to tighten the bolts of the gland, or remove the gland andadd new "V" ring. The problem canbe solved.

After the valves pass the test, the cylindrical pin is punched between the yoke and top flange to fix the position. This ensures the stabilty of the quality.

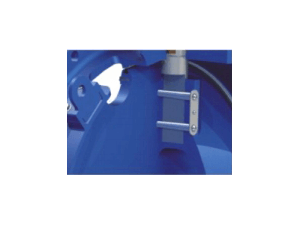

The disc is fixed with taper pins, the taper pins were fixed on the disc with shim and bolts. This effectively prevents the taper pin from loosening, and ensures that the connection of the disc and the stem was more stable.

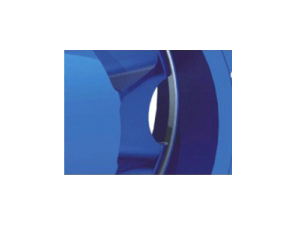

The body is sealed by stainiess steel body seat and rubber sealing ring of the disc. The high hardness and good resistance of attrition of the stainless steel seat ensure the long service life of the valves.

Environmental-friendly

The rubber sealing ring of the disc is fixed in the groove by two sets of bolts and one retainer ring. The rubber ring is extruded and defomed by adjusting the first set of the bolts to form the seal with the body seat, and the second set of bolts were used to maintain the deformation of the sealing ring. In the use, if there was the leakage in the body seat, the two sets of bolts can be adjusted to seal.

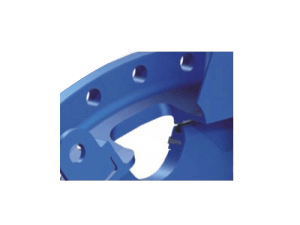

There are four connecting devices around the body, the body feet and hoisting rings can be mounted on these devices. It's easy to install the valves vertically or horizontally by changing the installation position of the body feet and the hoisting rings.

There are two "O" rings in the bottom seal, one is between the body and stem, an other is between the body and bottom seal. The sealing performance is improved with double protection.

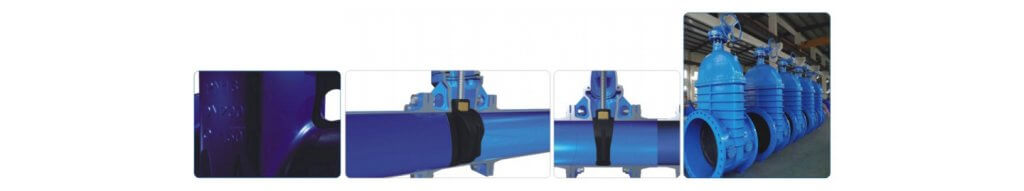

NRS resilient soft seated flange gate valve

FRS resilient soft seated flange gate valve

NRS resilient soft seated (PVC/PE PIPE)socket gate valve

NRS resilient soft seated (DI PIPE) socket gate valves

Anti-theft NRS resilient soft seated gate valve

Electric actuated NRS resilient soft seated gate valve

Gate valves with extension spindle

Heavy type NRS resilient soft seated flange gate valve

BS Electric soft-seal gate valve

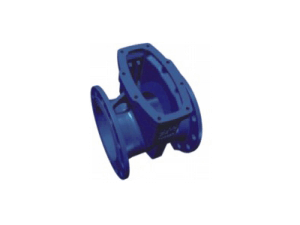

Body of resilient soft seated gate valve:

The body is made of ductile iron by presision casting molding. It was designed by 3D software, with finite element analysis for the structure. The safety coefficient is over 2.5. The bottom of the channel is without groove, no accumulation of rubbish, and with small flow resistance.

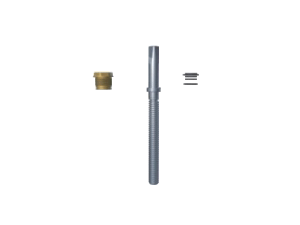

Stem of resilient soft seated gate valve:

The stem is made of stainless steel by rolling. Integral type, avoiding the use of the brass half rings to reduce stem diameter. The smooth modified ladder type screw is extruded. Global mirror polish, it fits the O rings well, to ensure that the rolation is flexible and labor saving.

Wedge of resilient soft seated gate valve:

The frame of the wedge is made of ductile iron by the percoated sand molding, the wedge is covered by EPDM totally. Double seal design, each seal line can work indepindently.

Bonnet of resilient soft seated gate valve:

The grade 8.8 bolts connect the bonnet and the body , the bolts were covered by hot-melt glue which protect the bolts for anti-corrosion. The gasket between the bonnet and body is made of EPDM. The vavle cover is with a retaining groove, make sure that the rubber gasket won't be extruded out under high water pressure.

The inside and outside surface of the valve is coated with sanitary epoxy powder by static

electricity , the average thickness is above 250 um.The adhesion of the coatig is strong; It won't

be destroyed under the impact force test of 3J. Internal parts can meet with the environ mental

protection demand, and can be used for the potable water, food and pharmaceutical area

directiy. The electrostatic powder coating process can promise high adhesion force and strong corrosion resistance.

The rubber parts are made of high quality EPDM orNBR, which is in accordance with the dinking water requirements, avoiding the problem of the common rubber whith is easy to breed microorganism. The products is not only approved by the national qulity standerds for drinkirg water related products, but also reached the UK WRAS standards. The stem nut is forged and rolled from the national standard brass rod (low lead), and no pollution to water.

We offer various kinds of interface such as flange connection, PVC pipe socket, Ductile iron pipe socket, reducing etc.). The special connection design can be developed as the requests of the customers. The gate valves can be operated by electric actuator, handwheels, square nuts or special key. lt's convenient to install the valves in different positions of the pipe lines. Except for the vertical installation, the valves also can be horizontal installation. In some narrow spaces, you can choose the installation way which is convenient for the operation of the valves.

The valve can be completely closed and reach at 0 leakage wih small torque. The actual operating torque is only 80% of diameter, and the gate valves can bear the MST of 3'' DN N.M. The products passed the switch life test of 500 times. For the valves of bigger diameter, we can offer the labour saving devices, to ensure that all the valves can be opened and closed by one person. The handwheel is strong, with accurate dimensions, it fits well with the valve stem, the shape is in accordance with human mechanics, to ensure easy operation.

The seal ring can be replaced without cutting off the water, it's easier for the maintenance and reduce the maintenance time as much as possible. The friction between the brass bushing and the "O" type seal ring is small, and the seal can work for long time. The Max. Operate torque is under the control.