Case

Case

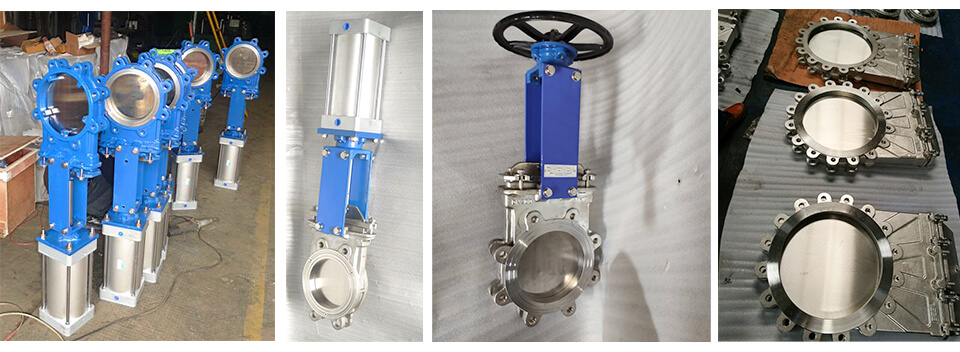

Knife gate valve is suitable for power plant, mine, paper making, metallurgy, chemical industry, sewage treatment and other kinds of wear, corrosive slurry and particle pipeline for opening and closing or regulating the flow.

Applicable nominal pressure 0.6Mpa ~ 1.6Mpa, adapt to the temperature -40℃ ~ 1000℃, the structure form is divided into hard seal and soft seal two types, sealing performance is good, the valve body is carbon steel or stainless steel material, high compressive strength, sealing surface wear resistance, easy installation, ash and ash less phenomenon, long service life.

1. The circular DC channel design of knife gate valve does not store slag and does not jam. The bottom end of the valve plate is processed into the blade shape, which can cut off the fly ash, ash, paper pulp, etc., and has a good opening and closing effect.

2.The disc is fine polished to obtain the best sealing effect. Compact design, occupy small space, light weight, cheap price, easy to install, wear-resisting and blocking measures perfect, easy to maintain, easy to use and long life, and can be arbitrarily selected driving device.

3.The valve body and the packing culvert are precision casting, in which the valve body is cast as a whole, the material can be selected according to the user needs WCB, 304, 316, 316L, 2520, the packing is made of graphite packing, PTFE PTFE material, corrosion resistance, wear resistance, non-slag.

4.The valve plate has 3 support points, so that the valve plate has a good self - alignment. The disc does not deviate when the valve is closed and under back pressure.

5.The drive mode of knife gate valve can be configured with handwheel, electro-hydraulic, sprocket, bevel gear, pneumatic, hydraulic and electric.

6.Knife gate valve connection forms are clamp type, flange lug type, sealing metal to metal hard seal, metal to rubber, polyurethane, polytetrafluoroethylene soft seal.

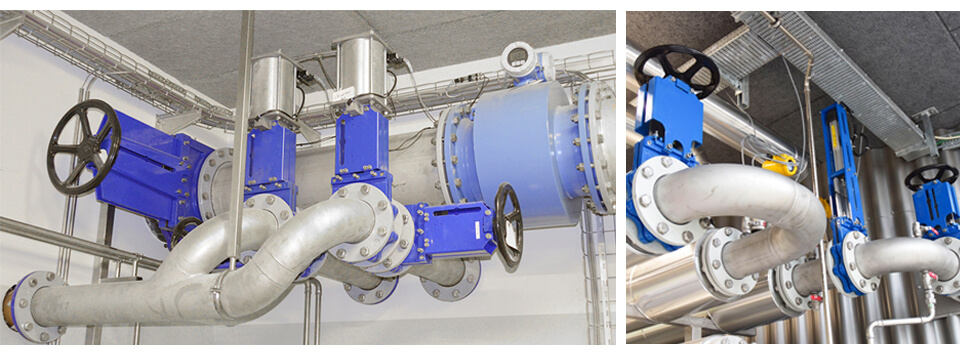

Mining, coal washing, iron and steel industry - used for washing coal pipeline, filter slag slurry pipeline, ash discharge pipeline; Purification device - used for rainwater, waste water, mud, dirt and clear water with suspended solids; Paper industry - for any concentration of pulp, feed water mixture; Power Plant Ash Removal - Used for ash slurries.

1. Please keep it in a dry and clean room. After long-term storage, it should be cleaned before installation, and check whether the bolts are loose.

Read this instruction carefully before installation and check valve number, size and technical parameters.

2. It is strictly prohibited to weld the flange after installing the valve, so as not to damage the valve sealing ring. Between the pipeline reserved valve installation distance should be appropriate, flange on both sides of the gasket. Installation should ensure that the valve work, maintenance, replacement on the convenience.

3. The center of the two pipelines and the center of the diameter of the valve should be kept coaxial, the flange surface should be flat, and the flange surface is not allowed to have a large deviation, so as to ensure the clamping and normal operation of the valve. The bolts should be tightened evenly and symmetrically.

4. During loading and unloading, the sling is not allowed to be used on the handwheel, cylinder and valve stem.

5. Please pay attention to the following matters when the valve is installed in the gray warehouse:

① When the valve is opened, please first run the feeder and dual-shaft mixer installed under the valve for about one minute to empty the ash in the pipeline under the valve, and then open the valve.

② When the valve is closed, please close the valve first, wait for one minute and then close the feeder and the dual-shaft mixer.

| Fault phenomenon | ause | Prevention and solution |

| Valve does not operate or switch is not in place | 1、Packing is too tight and skewed | Adjust nut tightness on packing gland |

| 2、There are dirt and dust between valve body and valve plate (valve cavity) | Cleaning and dressing remove dirt and extend air delivery time | |

| 3、Wear stem, stem nut or stem bent out of shape | Replace stem and stem nut | |

| 4、Insufficient air source pressure (pneumatic) | Increase air source pressure | |

| 5、Cylinder cylinder whether damaged (pneumatic) | Check whether the cylinder is out of round, if damaged replace the cylinder | |

| 6、Solenoid valve or stroke switch signal failure (pneumatic) | Check or replace solenoid valve, travel switch | |

| 7、Limit fault or no action of electric actuator (electric) | Check or replace the electric actuator | |

| Leakage at packing | 1、Packing not compacted | Tighten nut on packing gland |

| 2、Packing failure | Change the packing | |

| Sealing surface leakage | 1、The handwheel has not reached the bottom | Tighten the handwheel |

| 2、Wear or dirt on sealing surface | Disassemble repair, grind sealing surface or remove dirt |