Case

Case

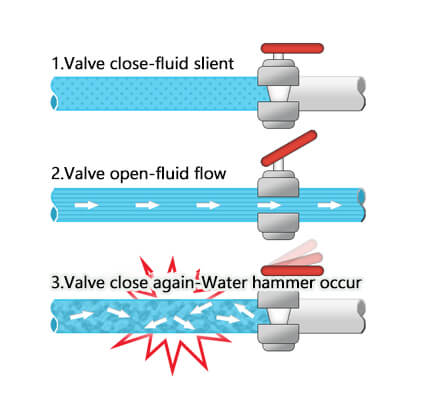

Water hammer, is a hydraulic transition phenomenon in which pressure changes are caused by sudden changes in water velocity in pressure pipes, also known as transient flow. That is, in a pressure pipeline, when the water flow changes sharply for some reason, the pressure of the liquid in the pipeline will increase or decrease due to the inertia of the fluid. It is very harmful to the pump unit and piping system. Under normal circumstances, water hammer will not occur during normal operation and normal shutdown of the pump.

From different angles, water hammer phenomenon can be divided into 4 categories:

(1) According to the relationship between valve closing duration and water hammer phase, it can be divided into direct water hammer phenomenon and indirect water hammer phenomenon;

(2) According to the fluctuation of water hammer, it can be divided into continuous water hammer phenomenon of water column and water hammer phenomenon of separated water column;

(3) According to the hydraulic characteristics of water hammer, it can be divided into rigid water hammer phenomenon and elastic water hammer phenomenon;

(4) According to the external conditions of the cause of water hammer, it can be divided into the phenomenon of starting water hammer, closing the valve water hammer and stopping the pump water hammer.

Pump stop water hammer is a kind of water hammer phenomenon. It is caused by the pump station staff's misoperation, accidental tripping of the external power grid, and natural disasters (gale, lightning, earthquake) and other reasons, which lead to the sudden power failure of the pump unit, resulting in the shutdown of the pump. Water hammer phenomenon in stations and pipeline systems.

According to the survey, many water hammer accidents belong to the water hammer accident of pump shutdown, which poses a great threat to the safety of the pump room and pipeline. The line is broken.

Although the duration of the water hammer phenomenon is short, the engineering accidents caused by it cannot be ignored. If it is light, the water pump unit will generate vibration and hydraulic impact noise; If the pump is shut down due to an accident, water column separation and water hammer will be caused in the pipeline, and the destructive power will be more serious.

How to protect against pump stop water hammer

Since the water hammer of stopping the pump may cause serious accidents in the pump station and the water delivery system, it is necessary to take corresponding measures to eliminate the water hammer of stopping the pump or reduce the pressure of the water hammer according to the specific situation. So far, there have been a variety of protection measures against pump stop water hammer, which can be roughly divided into:

Water replenishment (air injection) and pressure stabilization can prevent water column separation or over-pressurization cut-off to bridge water hammer. Belonging to this type are two-way surge chamber, one-way surge chamber and pressure tank.

(1) Two-way surge tower: built near the pumping station or at an appropriate location of the pipeline. The water surface height of the two-way surge tower should be higher than the water surface height of the receiving pool at the end of the water pipeline and the head loss along the pipeline should be considered. The surge tower will replenish water to the pipeline or release the excessive pressure in the pipeline according to the pressure change in the pipeline, so as to effectively avoid or reduce the water hammer pressure.

(2) One-way surge tower: It is built near the pumping station or at an appropriate location of the pipeline, and the height of the one-way surge tower is lower than the pipeline pressure there. When the pressure in the pipeline is lower than the water level in the tower, the surge tower will supply water to the pipeline to prevent the water column from being broken and avoid water hammer.

(3) Pressure tank: There is not much experience in domestic use, but it is widely used abroad. It works using specific laws of gas volume and pressure. As the pressure in the pipeline changes, the pressure tank supplies water to the pipeline or absorbs the excessive pressure in the pipeline, and its function is similar to that of a two-way surge tower.

Drainage and depressurization can avoid a sharp rise in pressure. This type includes pump stop water hammer eliminators, slow-closing check valves, and burst diaphragms.

(1) There are three main types of pump stop water hammer arresters, bottom open pump stop water hammer arrester, self-closing pump stop water hammer arrester, and automatic reset pump stop water hammer arrester. They are similar in working principle, that is, when the outlet pressure drops to a certain value during the pump stop process, the eliminator opens, and when the water hammer boost wave returns to the pump, the eliminator discharges water outward, thereby eliminating the water hammer. The length of the main pipe protected by the water hammer eliminator generally does not exceed 800m.

(2) Slow-closing check valve is a kind of check valve. It eliminates water hammer through slow-closing. There are many forms, simple and feasible, and it has been widely used. There are two types of slow-closing check valves: hammer type and energy storage type. This kind of valve can adjust the closing time of the valve within a certain range according to the needs. Generally, 70% to 80% of the valve is closed within 3 to 7 seconds after the power failure, and the remaining 20% to 30% closing time is adjusted according to the conditions of the water pump and pipeline, generally in the range of 10 to 30 seconds.

(3) The bursting diaphragm is similar to installing a fuse on the circuit. When the pressure in the pipeline exceeds the predetermined value due to water hammer, the diaphragm will automatically rupture, and the water will leak out, which will eliminate the water hammer by releasing water and reducing pressure.

(1) Appropriately increase the diameter and wall thickness of the pipeline, and reduce the flow rate of the water pipeline, which can reduce the water hammer pressure to a certain extent.

(2) Reduce the length of the pipeline, change from one pumping station to two pumping stations, and connect the two pumping stations with a suction well.

(3) The water hammer value can be reduced to a certain extent by selecting a water pump unit with a large moment of inertia or adding a flywheel with sufficient inertia.

(4) Change the layout of the vertical section of the pipeline. When laying out water pipelines, drastic changes in slope should be avoided as far as possible.

In addition, the following points should be paid attention to when choosing the protective measures against pump stop water hammer:

(1) The protective measures selected should be compatible with the scale, function, safety requirements and technical (management) level of the pumping station and pipeline system, and the safe and reliable technology, economical and reasonable, and management should be selected as much as possible. Maintenance-friendly protective measures.

(2) In the case of possible water hammer hazards, early prevention and control should be carried out. For example, in the design of the pumping station and piping system, the selection of the direction of the pipe, the selection of the pump unit and the pipe, and the determination of the flow rate in the pipe, etc., measures to eliminate or reduce the hazard of water hammer should be considered.

(3) According to the specific situation, comprehensive preventive measures (several measures are adopted at the same time) should be adopted as much as possible to improve the safety and reliability of the protective function.

(4) Sufficient attention should be paid to the management, maintenance and operation of protective measures. Many domestic major pump station water hammer accidents are caused by poor maintenance or misoperation of protective equipment.

(5) The selection of protective measures must be carried out simultaneously with the precise calculation and mutual analysis of the pump stop water hammer.

In short, the water hammer phenomenon and its hazards, like any specific physical phenomenon, are produced under specific conditions. Therefore, most of the preventive measures are based on the early protection of the water hammer when the pump is stopped. In actual engineering, its essence should be grasped, comprehensively considered, and flexibly applied