Case

Case

How to install and maintain joints?

A dismantling joint for joining a first pipeline component to a second pipeline component including a first half and a second half, the first half including a cylindrical spigot having an outer face and a flange extending outwardly from the outer face of the spigot, the flange having an inner face and an outer face remote from the inner face, and the second half including a socket adapted to slidably receive therein the spigot of the first half, the socket having a proximal end and a distal end remote from the proximal end, the proximal end being opposed to the inner face of the flange of the first half;

And forcing means arranged between the inner face of the flange of the first half and the proximal end of the spigot to engage the inner face of the flange of the first half and the proximal end of the socket of the second half adjacent the outer face of the spigot to force the first and second halves away from each other.

Installation instructions:

①Before the installation , the nut of the gland screw can be

tightened symmetrically , and then start installation with the valve .

②During the installation , please confirm the center distance between the dismantling joint and the connecting flange of the valve and the pipeline shall be same .

③The valve and pipeline shall be balanced and checked symmetrically , and all the pipeline valves shall be equipped with support and the brackets .

④The flow direction of the dismantling joint shall be confirmed before installation .

⑤After the installation, tighten the nuts of the gland screws of the expansion joint by diagonal tightening method.

⑥If there is no support, the concrete support shall be used to support the valve and the lower part of the expansion joint device, so as to make them integrated.

Product description:

The self-restrained dismantling joint type "PO" allows the installation and removal of valves pieces or flanged pipes. An active adjustment length until ± 25 mm is possible during the assembly.

The transmission of the forces is carried out by the threaded rods on the counter flange.

Transport:

The transport of the pieces must be done professionally in order to avoid damages on the material.

Storing:

The self-restrained dismantling joint must be protected from bad weather and pollution. During a long storage period a protection against UV is necessary.

Assembling in the pipe network:

It is necessary to control that the flanges to be connected are clean and not damaged. The flanges must be installed in parallel and centered.

Assembly:

①To fix the first flange with the flange of the pipe or the valve. The two flanges must be centered and parallel. The flat tightness seals (to be provided by the customer) will also be installed centered.

②The nuts of the first connection are to be tightened (tightening torque according to information given by the supplier of the joint).

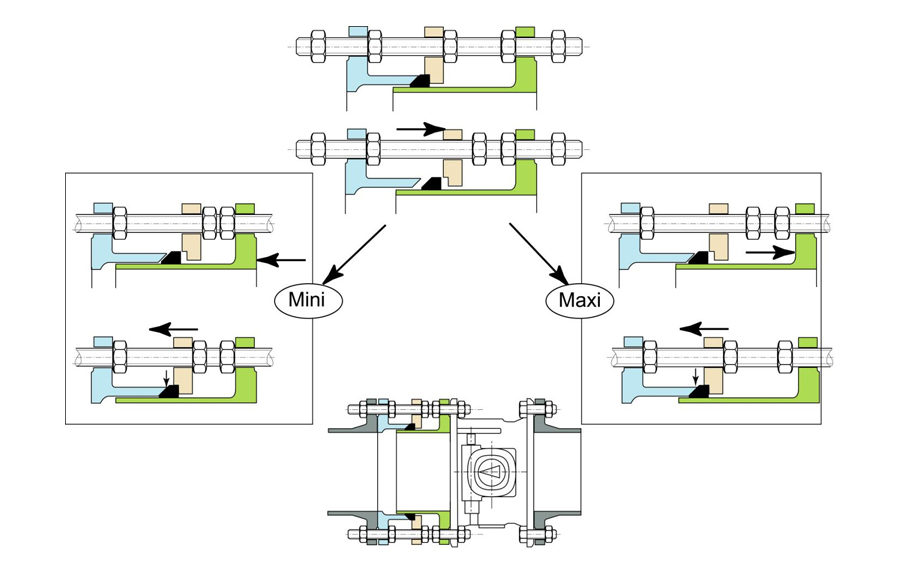

③Assembly of the second connection taking into account the necessary mini and maximum length of the dismantling joint (A).

④After the assembly of two connections, it is necessary to push the tightness seal against the external pipe

⑤Then it is necessary to tighten the nuts with the ring of tightening (3). Once the assembly of the pipe finished and the length of the dismantling joint defined, it is necessary to tighten the nuts in cross.

⑥The dismantling joint is now ready for operation and can receive the axial thrust of the pipe.