Case

Case

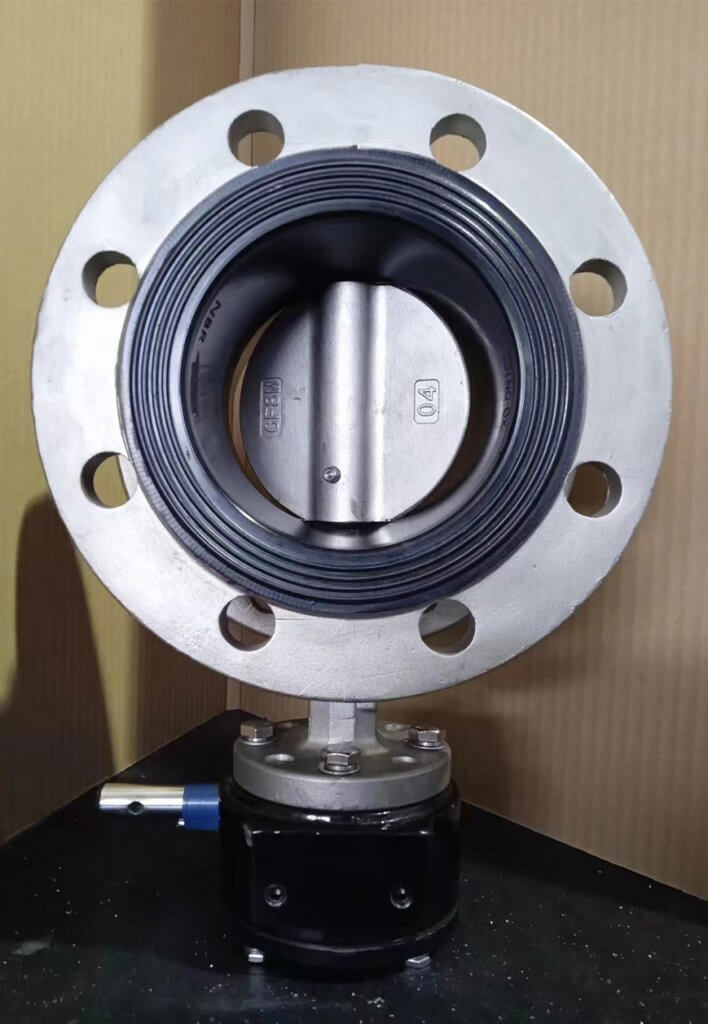

The QT450 DN100 resilient seated wafer butterfly valve is a butterfly valve that uses elastic materials as sealing elements to adjust the flow and pressure of the fluid through the rotation of the butterfly plate. Its core components include valve body, butterfly plate, sealing ring and driving device. Elastic sealing butterfly valves are usually used in situations that require precise control and rapid opening, and are widely used in chemical, petroleum, natural gas, water treatment and other industries. Compared with traditional hard-sealed butterfly valves, resilient seated butterfly valves have better sealing performance and are especially suitable for medium and low pressure applications.

The working principle of the stainless steel resilient seated flange butterfly valve is based on the rotational movement of the butterfly plate. When the butterfly plate is in a closed state, it is in close contact with the sealing surface of the valve seat, preventing fluid from passing through; when the butterfly plate rotates to the open position, fluid can pass through the valve. The rotation angle of the butterfly plate is usually between 0° and 90°, and its angle is controlled by the operation of the driving device to achieve flow adjustment. The sealing performance of the resilient seated butterfly valve relies on the elastic contact between the valve seat and the butterfly plate, which effectively prevents leakage through this contact.

The seat materials of resilient seated butterfly valves are diverse, including rubber, polytetrafluoroethylene (PTFE), EPDM (ethylene propylene rubber), etc.

Choosing the appropriate valve seat material is crucial and usually depends on the specific working conditions:

1. Rubber: Commonly used in general water and air systems, it has good elasticity and corrosion resistance, but is not suitable for high temperature or oily media.

2. Polytetrafluoroethylene (PTFE): It is suitable for situations with corrosive media in the chemical industry. It can withstand higher temperatures and has strong corrosion resistance.

3. EPDM (ethylene propylene rubber): Suitable for cold water, hot water, steam, acidic and alkaline media, but not suitable for oil media.

The correct selection of valve seat materials requires consideration of factors such as the nature of the medium, temperature, pressure, and whether there is wear or corrosion. Ensuring chemical compatibility and the working life of materials is key.

Good sealing performance: The close cooperation between the resilient seated ring and the butterfly plate ensures efficient sealing performance and can effectively prevent leakage.

Quick opening and closing: It only needs 90° rotation to go from fully open to fully closed. The operation is simple and fast, saving time and labor costs.

Compact structure: Simple design, easy installation, saving space and materials, and reducing installation and maintenance costs.

Excellent adjustment performance: The rotation of the butterfly plate can accurately adjust the flow rate, and is suitable for fluid control under various working conditions.

Low pressure loss: Since the butterfly plate is in a streamlined position in the fluid, the fluid resistance is small, reducing pressure loss.

Cost-effective: Due to its simple design and lower material requirements, elastomeric sealing butterfly valves are less expensive to manufacture and maintain.

Versatility: Can be used to shut off, regulate and divert flow to suit a variety of industrial applications.

Corrosion resistance: Especially valves using materials such as polytetrafluoroethylene can effectively resist the erosion of various corrosive media.

Resilient seated butterfly valves are widely used in the following fields:

Water treatment system: Used to control and regulate water flow to ensure the smooth progress of water supply and sewage treatment processes.

Chemical industry: Suitable for fluid control of a variety of corrosive media, such as acids, alkalis, salts, etc.

HVAC system: Used in heating, ventilation and air conditioning systems to regulate air flow and temperature.

Food and Pharmaceuticals: Hygienic valve materials can be used for fluid control in the food and pharmaceutical industries, ensuring contamination-free fluid transfer.

To ensure the long-term stable operation of the resilient seated butterfly valve, correct installation and regular maintenance are necessary:

1. Installation: Ensure that the valve is aligned with the pipeline and installed with the valve open to prevent the butterfly plate from damaging the valve seat. Pay attention to tightening the bolts evenly to avoid uneven stress on the valve body.

2. Maintenance: Regularly check the sealing condition and operating status of the valve, especially under frequent operations or harsh conditions. Remove impurities on the butterfly plate and valve seat to keep the sealing surface clean.

3. Lubrication: Lubricate the connection points of metal parts regularly to prevent rust and wear. The elastic sealing material itself generally does not require lubrication, but contact with oil or organic solvents should be avoided.

4. Replace the seal: When the sealing performance is found to be reduced, the sealing ring should be replaced in time to ensure the normal use of the valve.

Resilient sealing butterfly valves have become indispensable fluid control equipment in many industries due to their excellent sealing performance, rapid opening and closing capabilities and versatility. Through correct material selection, standardized installation and reasonable maintenance, its service life can be greatly extended and work efficiency improved. Whether in the chemical industry, environmental protection, or food and pharmaceutical industries, resilient seated butterfly valves have demonstrated strong adaptability and irreplaceable value.