Case

Case

Ball valve is the most widely used mechanical product in all valve markets at present. It is mainly composed of valve body, valve seat, ball, valve stem and transmission device.

The ball core is driven to rotate by the actuator to achieve the function of switching or regulating . It is widely used in petrochemical, water conservancy, urban construction, heating and other industries.

There are many types of ball valves, which can be combined into various products with different functions through different structural forms, connection methods, pressure levels, and driving forms.

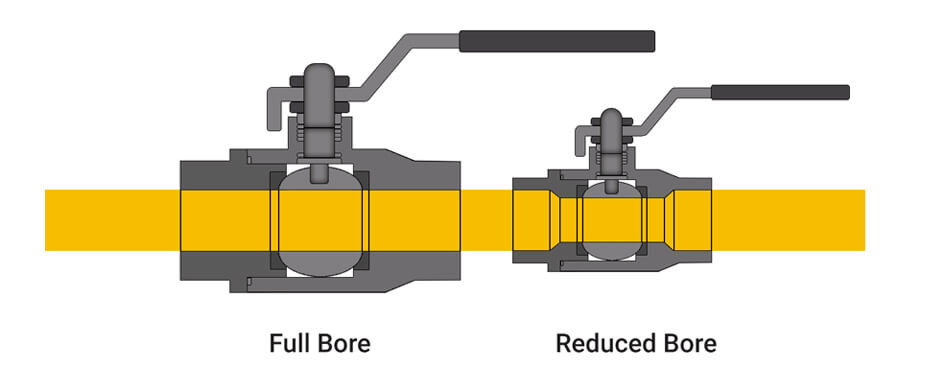

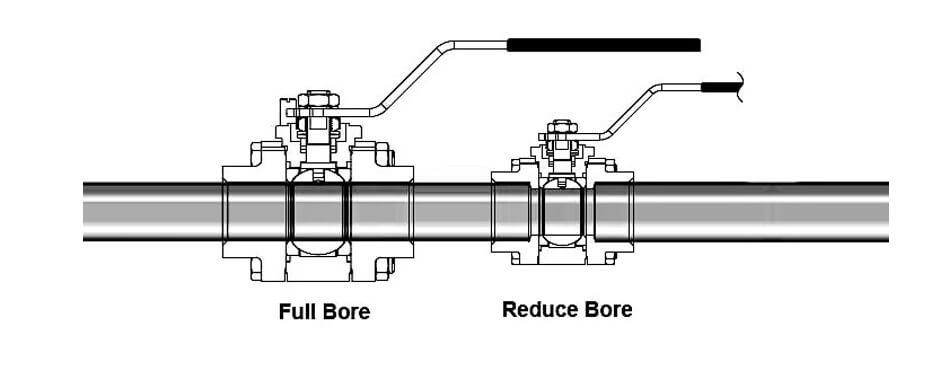

Generally speaking, when the inner diameter of the valve ball is less than or equal to 85% of the inner diameter of the ball valve port, it is called a reduced diameter ball valve, and when the inner diameter of the ball valve is greater than 95% of the inner diameter of the ball valve port, it is called a full bore ball valve.

1.The full-bore ball valve is an equal-width flow channel, that is to say, the size of the hole from the inflow to the outflow is the same, and its size cannot be smaller than the value specified in the standard, which is roughly equivalent to the nominal diameter of this specification, such as DN50 full-bore The diameter of the flow channel of the ball valve also needs to be about 50;

2.The inlet of the flow channel of the reduced-diameter ball valve is wider than the diameter of the flow channel, and the actual diameter of the flow channel is about one specification smaller than this specification.

For example, the diameter of the flow channel of the DN50 reduced-diameter ball valve is 38 It is roughly equivalent to the specification of DN40. For DN250 and below, shrink one specification, for DN250-600, shrink two specifications, and for DN250 and above, it depends on the actual situation.

1. Full-bore ball valves are generally used to transport viscous and slagging medium pipelines. Because of their small fluid resistance, it can be said that there is basically no flow resistance, and it is convenient for regular wax scraping and purging devices to pass through.

2.The reduced-diameter ball valve is suitable for pipelines conveying gas or media whose physical properties are similar to water, because its weight is about 30% lighter than that of a full-bore ball valve, and its flow resistance layer is 1/2 that of a globe valve of the same diameter. 7 or so. It is beneficial to reduce the pipeline load and reduce the cost.

1.For pipelines that require regular pigging, no matter what medium is transported, full-bore ball valves must be used. The medium will not reduce the flow through the full-bore ball valve, and the small flow resistance is an ideal product for pipeline control, especially for strict working conditions, especially in oil pipelines and gas pipelines. The main pipeline needs to be buried underground , a full bore welded ball valve must be used.

2. The reduced-diameter ball valve is suitable for some working conditions with low requirements and small flow resistance requirements. When the inner diameter of the valve is more than 80% larger than the inner diameter of the pipe end, it has almost no effect on the pipeline fluid passing capacity. Many shutters have a diameter reduction, which is generally controlled within 0.8.

On the one hand, the diameter reduction reduces the flow capacity of the valve, that is, the K value of the valve, increases the pressure on both sides of the valve, and causes energy loss. , without much impact, perhaps increasing the flushing of the pipeline.