Case

Case

Electromagnetic flowmeter is a flowmeter that performs flow testing based on Faraday's law of electromagnetic induction. The advantage of electromagnetic flowmeter is that the pressure loss is extremely small and the measurable flow range is large. The ratio of large flow rate to small flow rate is generally more than 20:1. It is suitable for a wide range of industrial pipe diameters, up to 3m. The output signal is linear with the measured flow rate and has high accuracy. It can measure acids and acids with conductivity ≥5μs/cm. Alkaline salt solution, water, sewage, corrosive liquid and fluid flow such as mud, pulp, paper pulp etc.

According to Faraday's electromagnetic induction principle, a pair of detection electrodes are installed on the tube wall perpendicular to the axis of the measuring tube and the magnetic field lines. When the conductive liquid moves along the axis of the measuring tube, the conductive liquid cuts the magnetic field lines to generate an induced electric potential. This induced electric potential is composed of two The detection electrode detects that the numerical value is proportional to the flow rate, and its value is:

E=KBVD

In the formula:

E - induced electric potential;

K - coefficient related to magnetic field distribution and axial length;

B - magnetic induction intensity;

V - average flow rate of conductive liquid;

D - electrode distance; (measuring tube inner diameter);

The sensor transmits the induced potential E as a flow signal to the converter. After amplification, transformation and filtering, and a series of digital processing, the instantaneous flow and accumulated flow are displayed on a dot matrix LCD with backlight. The converter has 4~20mA output, alarm output and frequency output, and is equipped with RS-485 and other communication interfaces, and supports HART and MODBUS protocols.

WESDOM is an enterprise specializing in the design, research and development, production and sales of instruments and flow calibration devices.

①It is not affected by changes in fluid density, viscosity, temperature, pressure and electrical rate, and the linear measurement principle can achieve high-precision measurement;

There are no flow blocking parts in the measuring pipe, the pressure loss is small, and the straight pipe section requirements are low;

②The nominal diameter DN10-DN2000 covers a wide range, with a variety of linings and electrodes to choose from, which can meet the requirements for measuring a variety of conductive fluids;

③The converter uses programmable frequency low-frequency rectangular wave excitation, which improves the stability of flow measurement and reduces power loss;

④The converter uses a 16-bit embedded microprocessor, full digital processing, fast operation speed, strong anti-interference ability, reliable measurement, high accuracy, and the flow measurement range can reach 1500:1;

⑤ High-definition backlit LCD display, full Chinese character menu operation, easy to use, simple to operate, easy to learn and understand;

⑥With RS485 or RS232O digital communication signal output;

⑦ It has conductivity measurement function, which can determine whether the sensor is empty, and has self-test and self-diagnosis functions;

⑧Using SMD devices and surface mounting technology, the circuit has high reliability;

⑨Can be used in corresponding explosion-proof situations.

| Performance | Technical Parameters | ||

| Nominal diameter | DN10——DN3000mm | ||

| Accuracy | ±0.5% of the indication value, optional ±0.3% or ±0.2% of the indication value | ||

| Lining material | PTFE, PFA, F46, neoprene, polyurethane rubber, high temperature rubber | ||

| Electrode material | SUS316, Hastelloy B/C, titanium, tantalum, platinum-iridium alloy, stainless steel coated with tungsten carbide | ||

| Connection method | Flange connection, plug-in connection, wafer connection, clamping connection | ||

| Medium temperature | Integrated type | -20℃~+60℃ | |

| Split type | Neoprene lining, polyurethane lining | -10℃~+80℃ | |

| PTFE lining, PFA lining, F46 lining | -10℃~+160℃ | ||

| Nominal pressure | 0.6~4.0Mpa(Special pressure can be customized) | ||

| Ambient temperature | -25℃~+60℃ | ||

| Dielectric conductivity | ≥20μs/cm | ||

| Measuring range | 1500:1 Flow rate setting<15m/s | ||

| Structure type | Integrated type, separate type, immersed type, explosion-proof type | ||

| Protection level | IP65、IP68 | ||

① Installation location: The electromagnetic flowmeter should be installed upstream of the pipeline to ensure that the fluid can be evenly distributed before entering the flowmeter. At the same time, the installation location should be convenient for maintenance and calibration.

② Pipeline preparation: Clean the inside of the pipeline to prevent residues in the pipe from affecting the electromagnetic flowmeter. Prepare corresponding flange and sealing materials, and prepare anti-vibration pads at the interface according to the size and specifications of the flow meter.

③ Installation method: Usually connected through flange, use correct tools and torque to tighten the flange to prevent leakage. Anti-vibration pads need to be installed at the interface to avoid interference caused by pipeline vibration.

④ Wiring method: Follow the wiring diagram in the electromagnetic flowmeter manual to ensure that the connection between the cable and the terminal is firm and reliable, and avoid interference between the signal line and the power line.

⑤ Calibration and trial operation: Calibrate after completion of installation to ensure the accuracy of the measurement results. Before trial operation, check whether all components are installed and tightened normally.

⑥ Environmental requirements: The installation location of the electromagnetic flowmeter should avoid the influence of strong vibration and strong electromagnetic field. It is recommended to install it vertically. If installed horizontally, make sure the two electrodes are on the same horizontal plane.

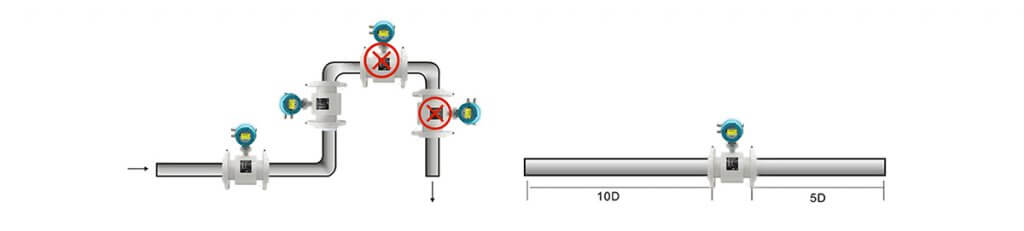

⑦ Straight pipe section requirements: Keep the first 10 and 5 times the pipe diameter as the straight pipe section, which is crucial to reduce the impact of bubbles and solid particles.

⑧ Welding installation: Avoid welding the flow meter to avoid damaging the flow meter.

⑨ Grounding measures: The transmitter shell, shielded wire, measuring tube and pipes at both ends of the transmitter need to be grounded, and separate grounding points should be set to improve measurement accuracy.

⑩ Direct sunlight: Avoid direct sunlight exposure of the electromagnetic flowmeter, which may cause high temperature.